Bean milk machine with hand-mill stirrer

The technology of agitator and soymilk maker is applied in the directions of milk substitutes, beverage preparation devices, household appliances, etc., which can solve the problems of inconvenient cleaning of appliances, potential safety hazards, inconvenient cleaning of the kettle body, etc., so as to reduce cleaning difficulty, low cost, The effect of combined structure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

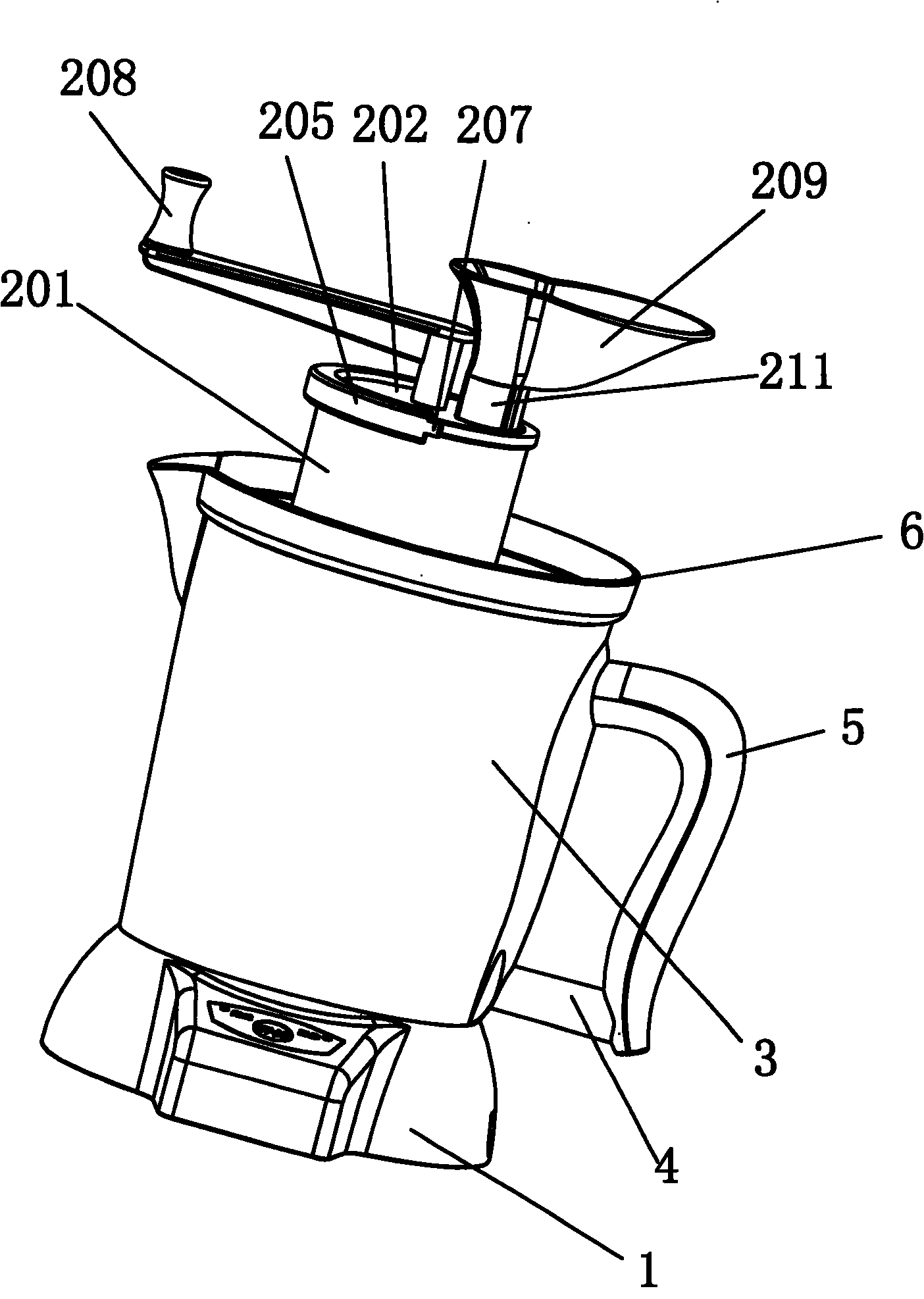

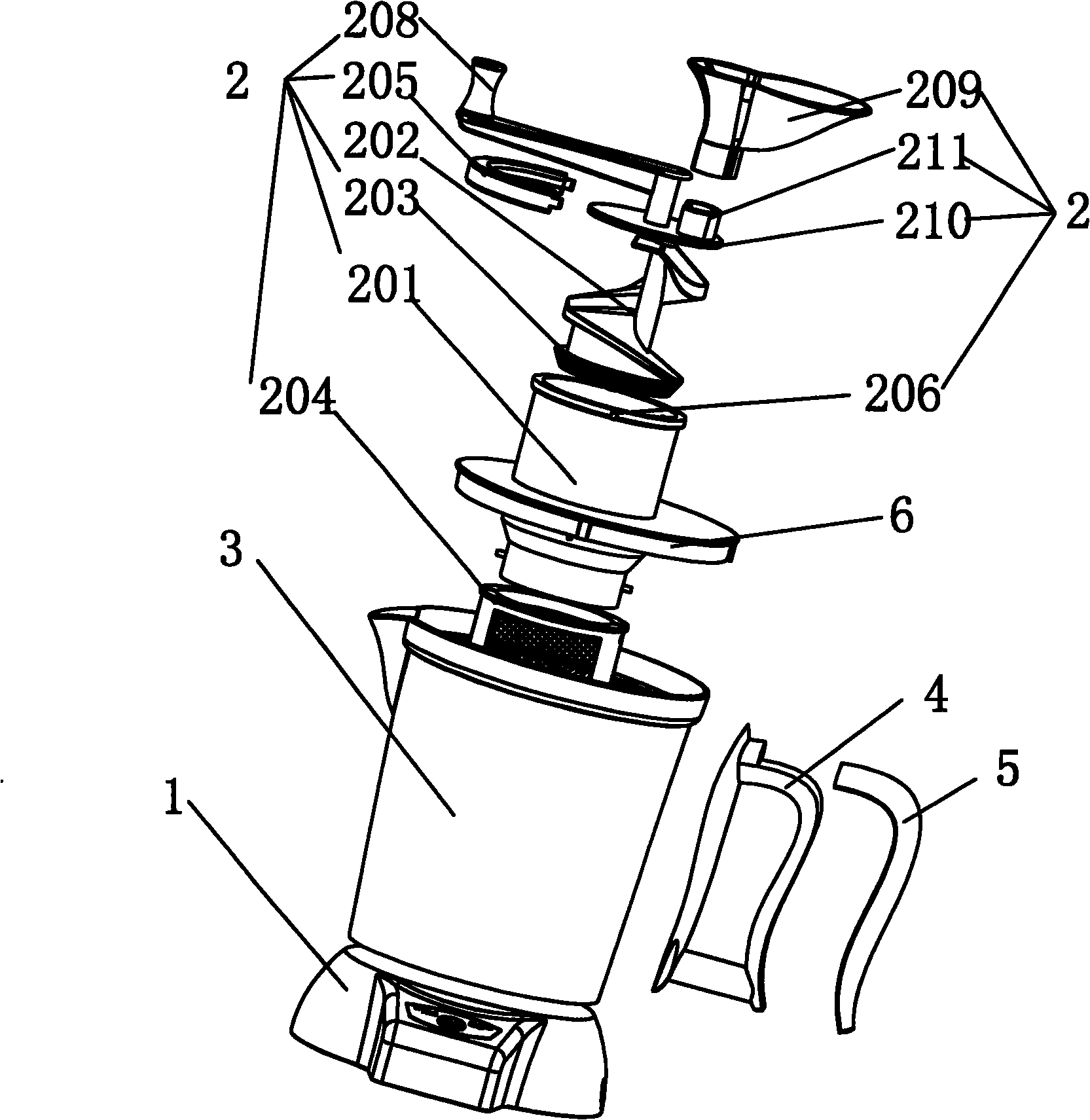

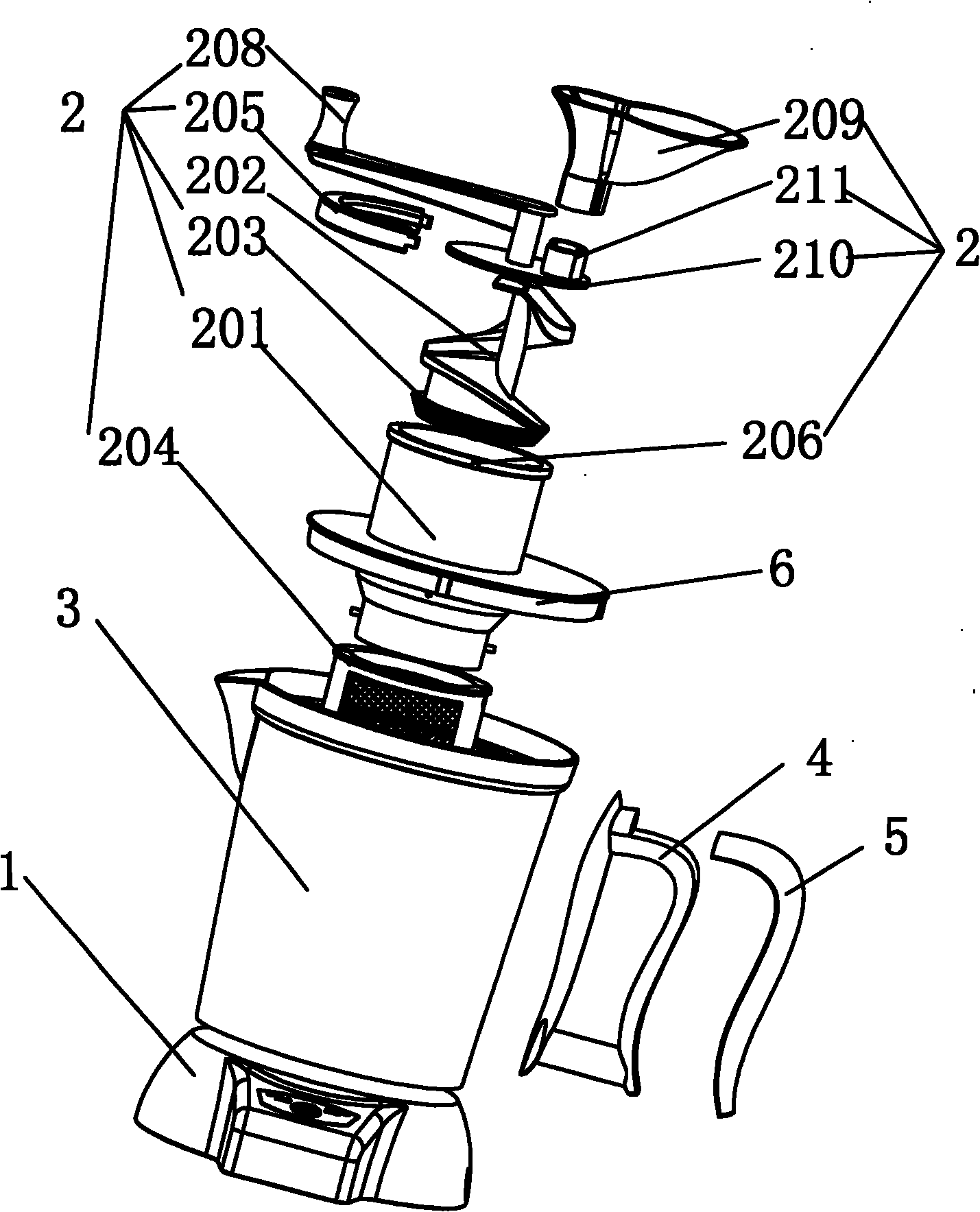

[0012] Hereinafter, the present invention will be further explained in detail with reference to the drawings.

[0013] As shown in the figure, it includes a main body 3, a base 1 and a feeding rack 6. The main body 3 is connected with a handle 4, the base 1 is provided with an electric heating element, and the feeding rack 6 is provided with a stirring device 2 which includes There is a cavity in the grinding cylinder 201, and there is a worm 202 in the cavity. One end of the worm 202 has a spiral grinding pattern 203, and the other end is provided with a rocker 208. The bottom of the grinding cylinder 201 is also provided with a spiral grinding pattern 203. Grinding, the bottom and middle of the grinding cylinder 201 are provided with slurry outlets.

[0014] A filter cover 204 is wrapped around the slurry outlet of the mill cylinder 201.

[0015] The outer circle limiting convex part 206 of the upper part of the grinding cylinder 201, and a locking member 205 locks the worm 202 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com