Deep hydrodesulfurization solid-acid catalyst of gasoline and preparation method thereof

A solid acid catalyst and deep hydrogenation technology, applied in the chemical field, can solve the problems of difficult long-term industrial operation, poor catalyst stability, etc., and achieve the effect of reducing sulfur content and good low-temperature aromatization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

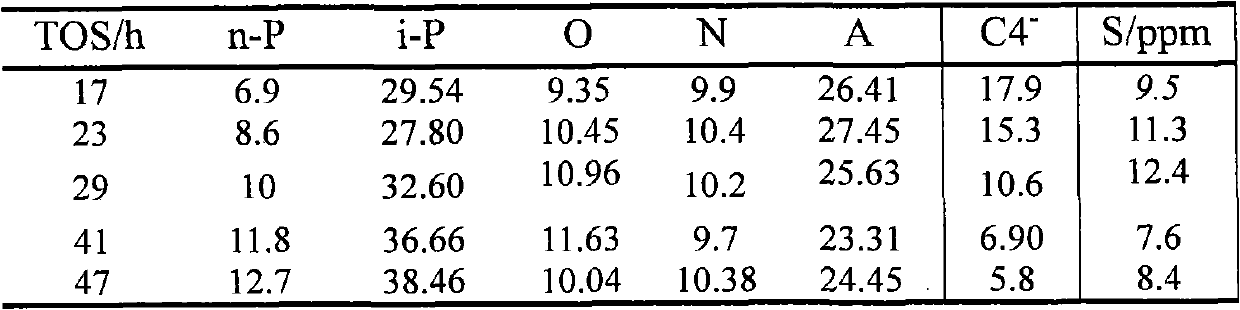

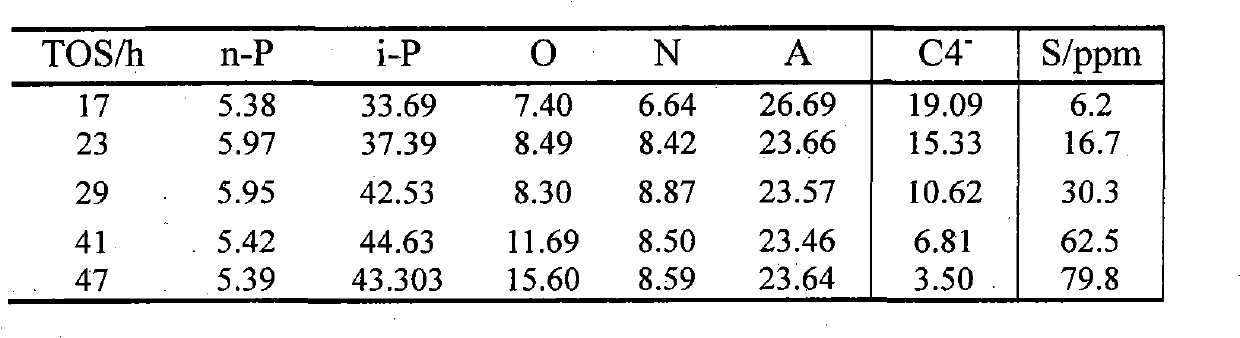

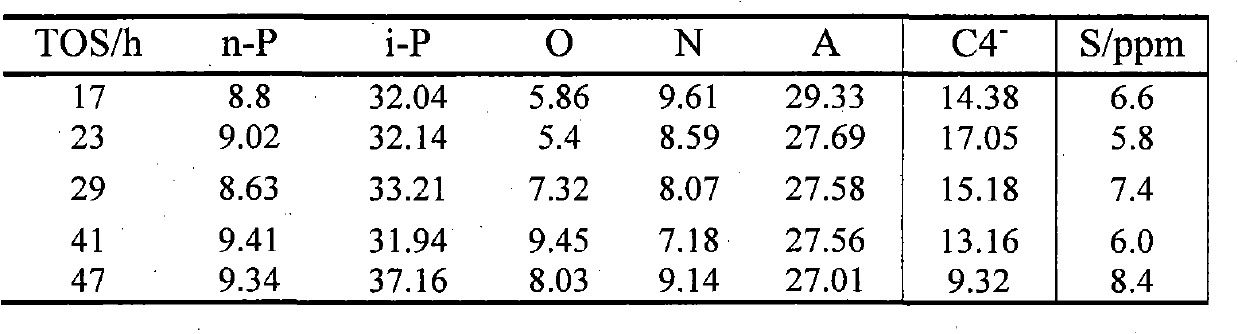

Examples

Embodiment 1

[0048] Weigh 1.0g of phosphotungsten POM and dissolve it in 4.5ml of water, and stir properly to obtain a colorless and clear solution. The NiHZSM-5 prepared according to Comparative Example 1 was impregnated by equal volume impregnation method, impregnated for 12 hours, dried at 150° C. for 12 hours, and calcined at 350° C. for 4 hours. Get Cat1.

Embodiment 2

[0050] Weigh 1.0g silicotungsten POM and dissolve it in 4.5ml water, stir properly to obtain a colorless and clear solution. The NiHZSM-5 prepared according to Comparative Example 1 was impregnated by equal volume impregnation method, impregnated for 12 hours, dried at 150° C. for 12 hours, and calcined at 350° C. for 4 hours. Get Cat2.

Embodiment 3

[0052] Weigh 1.0g phosphomolybdenum POM and dissolve it in 4.5ml water, stir properly to obtain a yellow clear solution. It was impregnated onto NiHZSM-5 prepared according to Comparative Example 1 by equal volume impregnation method. After soaking for 12 hours, dry at 150°C for 12 hours, and bake at 350°C for 4 hours. Get Cat3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com