Full automatic ultrasonic welding machine for plastic pen

An ultrasonic and fully automatic technology, applied in the field of welding machinery, can solve the problems of not being able to meet the production requirements, and the welding speed of the pen back cover and the nib cover can not keep up, and achieve the effect of solving production bottlenecks, improving efficiency, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

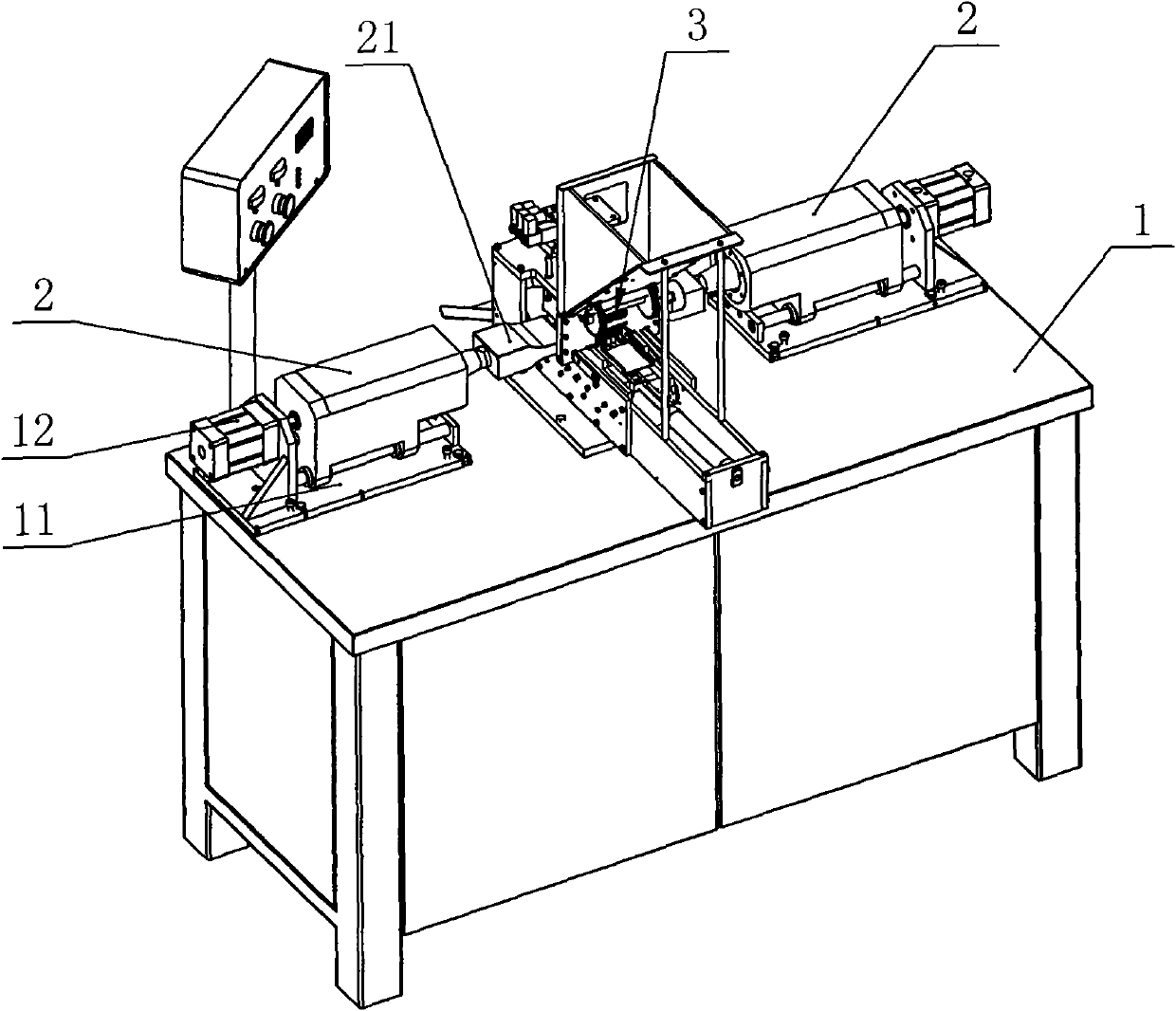

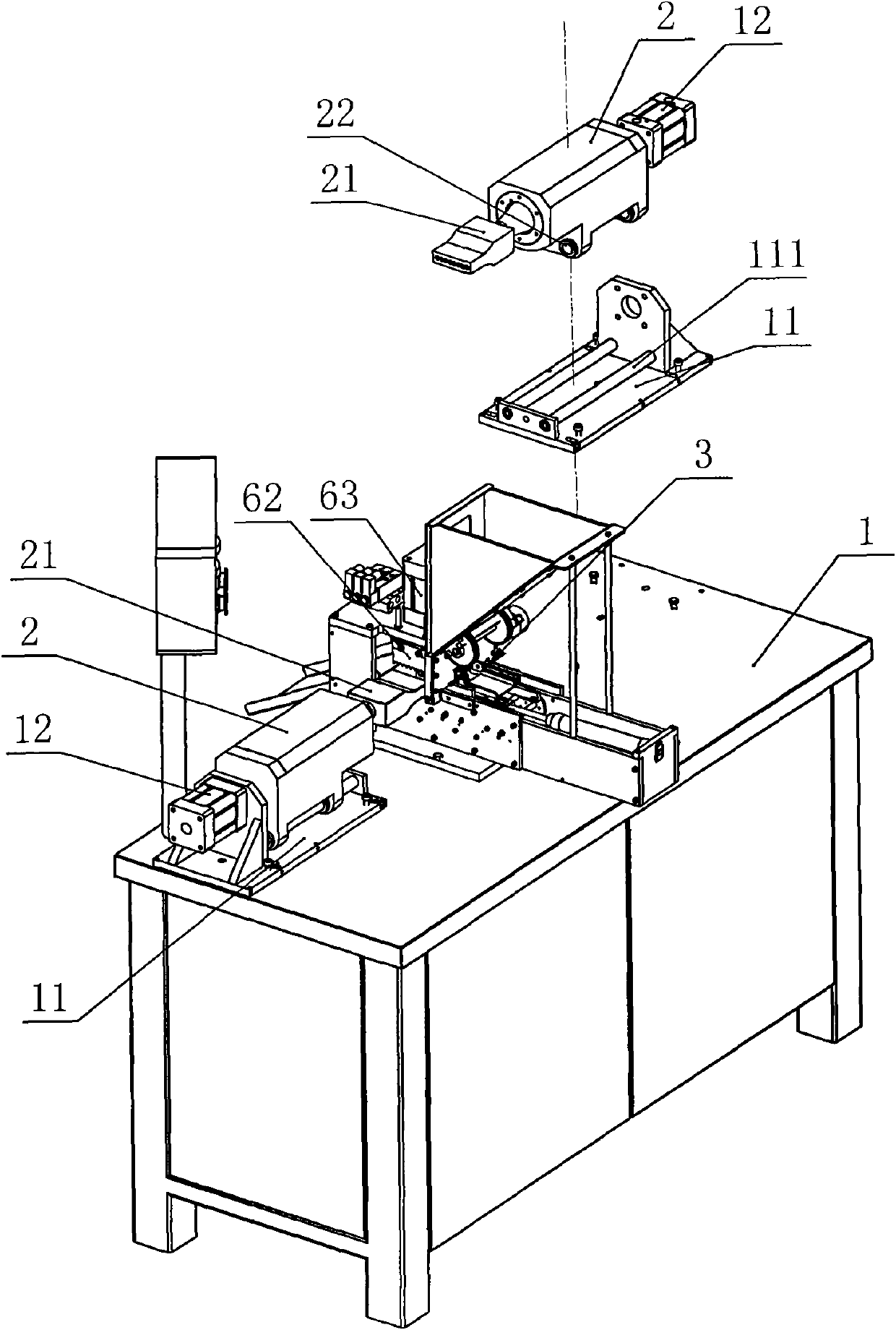

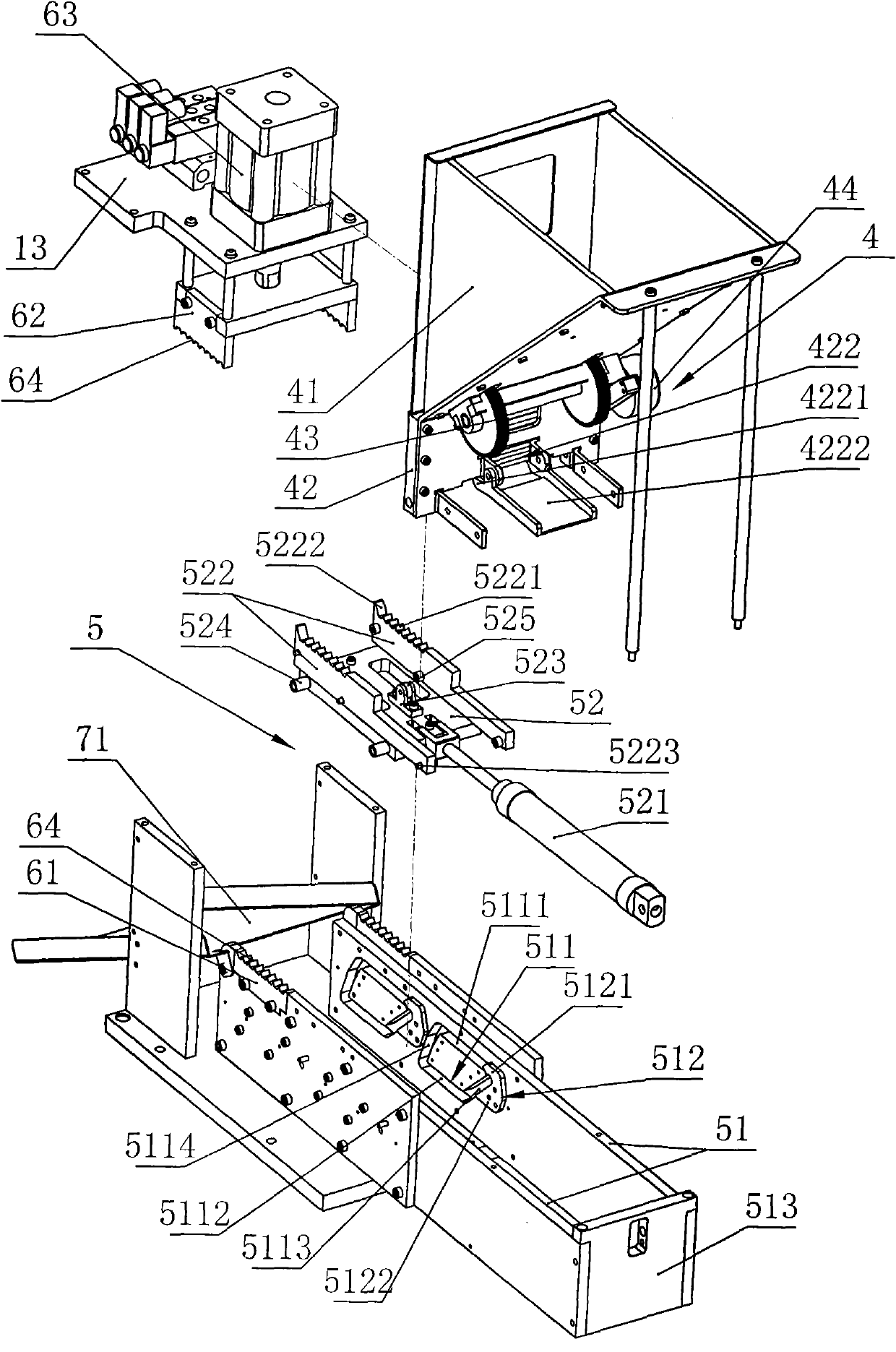

[0021] Such as Figure 1-3The specific embodiment of the present invention shown includes mounting frame 1, ultrasonic generator and transducer 2, and described transducer 2 is electrically connected with ultrasonic generator, and the head end of this transducer 2 is fixedly installed There is an ultrasonic welding head 21, the installation frame 1 described in the present embodiment is an installation cabinet 1, and the ultrasonic generator is arranged inside the installation cabinet 1 (not shown in the accompanying drawings) to simplify the mechanism setting on the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com