Tension control unit of flexible material

A tension control, flexible material technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of limited material storage, complex system, easy material breakage, etc., to achieve convenient adjustment and maintenance, low operating cost , the effect of stable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

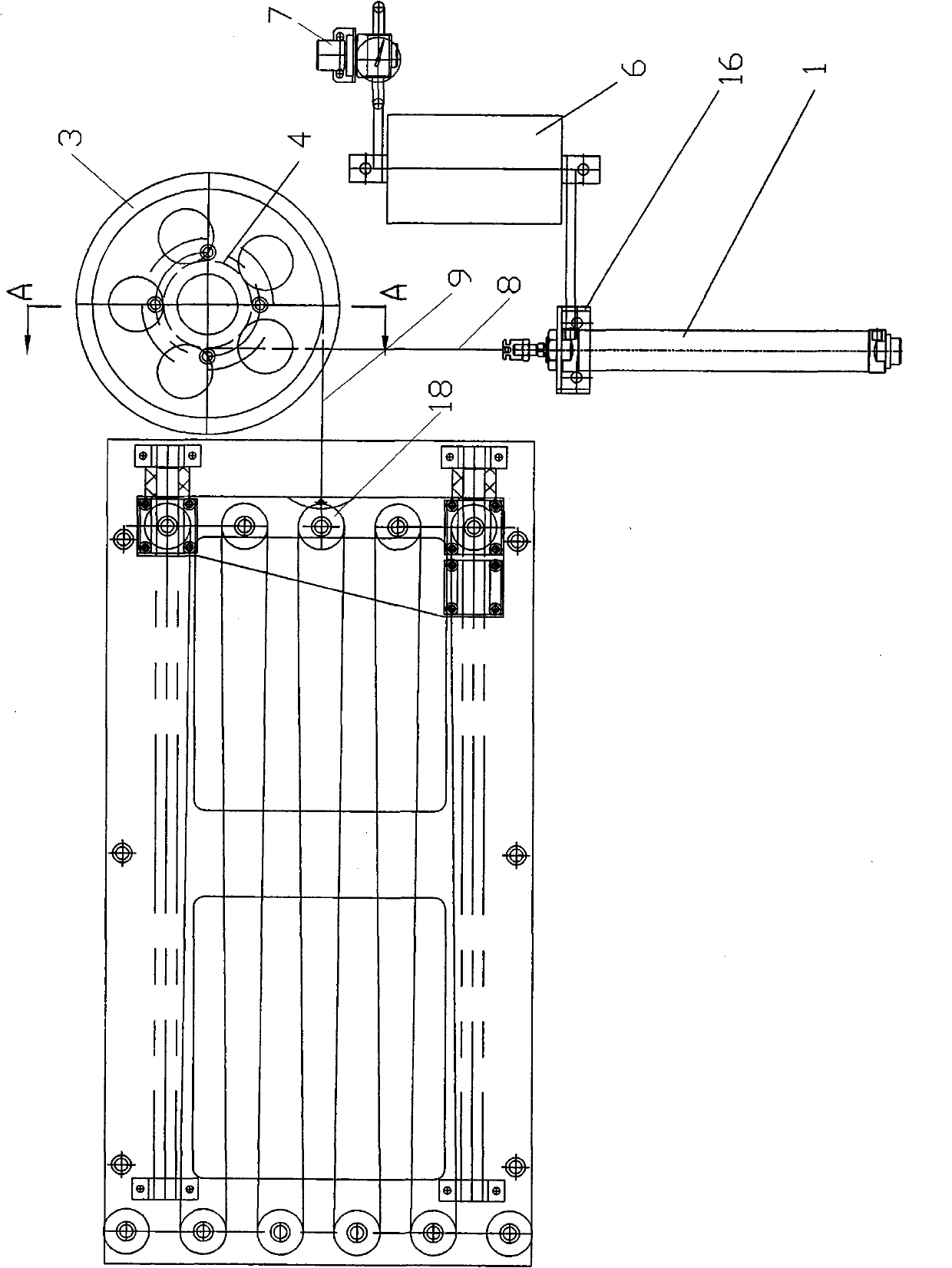

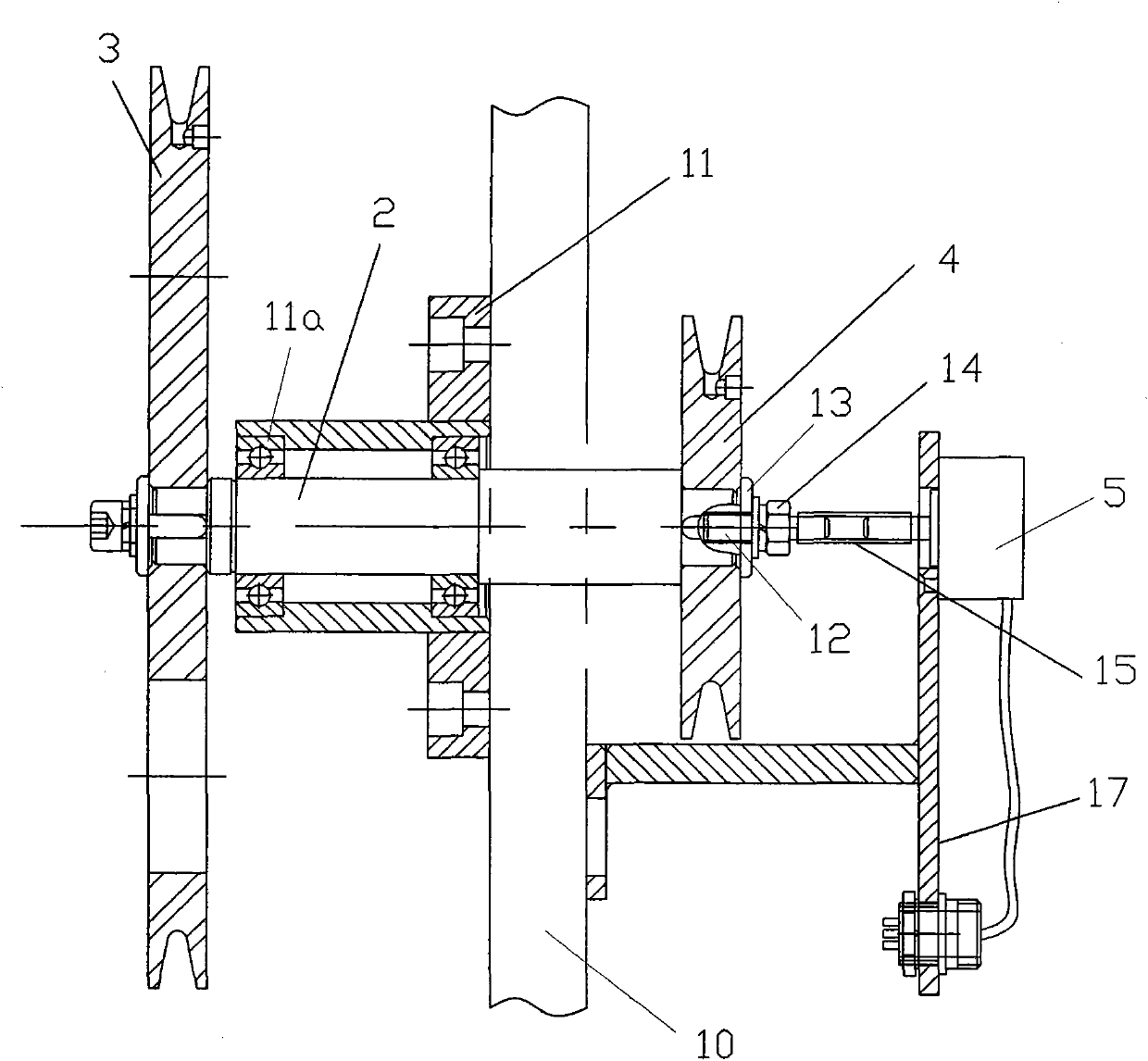

[0015] like figure 1 and figure 2 As shown, the present invention is a flexible material tension control device, including a cylinder 1, a rotating shaft 2, a large wheel 3, a small wheel 4, a potentiometer 5, an accumulator 6, a pressure regulating valve 7, a first wire rope 8, a second Wire rope 9, wallboard 10, bearing block 11, stud 12, end cap 13, nut 14, sleeve pipe 15, cylinder support 16, potentiometer support 17 and control system. Wherein, the rotating shaft 2 is installed on the wallboard 10 through the bearing seat 11, and two bearings 11a are housed in the bearing seat 11, and the bearing 11a in the bearing seat 11 supports the rotating shaft 2, and the rotating shaft 2 passes through the wallboard 10, and the two ends of the rotating shaft 2 Located on both sides of the wallboard 10. The two ends of the rotating shaft 2 are respectively equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com