Light-emitting particles and preparation method and application thereof

A technology of luminescent particles and luminescent materials, applied in the field of building decoration materials, can solve the problems that luminescent materials cannot be effectively protected, glass microbeads are easy to absorb dust, and have no water permeability, etc., and achieve excellent luminous performance and excellent wear resistance. , the effect of increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

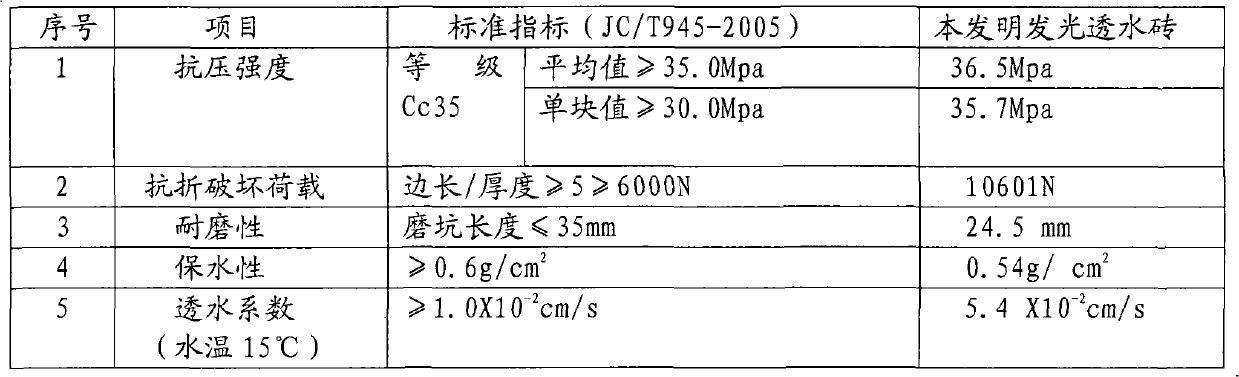

[0016] Heat 100 grams of quartz sand with a particle size of 0.2-0.4 mm to 100 ° C, and then add the pre-mixed mixture of the following materials, the mixture is 4.6 grams of hydrogenated bisphenol A epoxy resin, 0.46 grams of hydrophilic Epoxy resin, 1 gram of microencapsulated ZnS:Eu with a particle size of 0.1mm 2+ The luminescent material is added and stirred evenly, and after the temperature is lowered, it is crushed and sieved to obtain granular material A with a luminescent layer coated on the surface of quartz sand. Put the obtained material into the mold and form it into a luminous permeable brick with an initial brightness of 10cd / m 2 , 0.010cd / m after 10 hours 2 . ZnS in this embodiment:Eu 2+ The light-emitting material is a sulfide-based light-storage type self-luminous material. See Table 1 for the comparison of its performance indicators with ordinary permeable bricks.

[0017] The microcapsule encapsulation treatment in this embodiment is a technology for e...

Embodiment 2

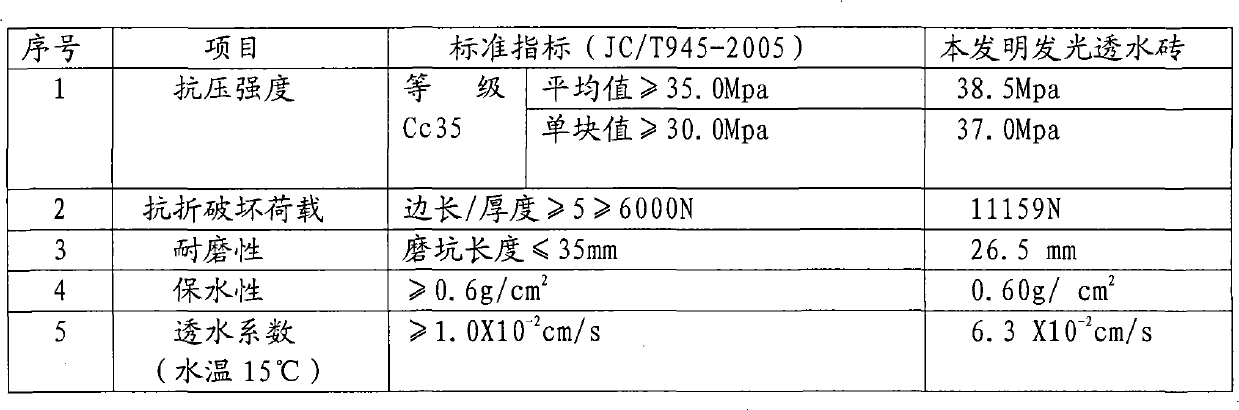

[0019] Heat 10kg of quartz sand with a particle size of 0.07-0.2mm to 200°C, and then add the pre-mixed mixture of the following materials, which is 94 grams of hydroxyl-containing acrylic resin, 6 grams of hydrophilic epoxy resin, granules Diameter is the CaSrS of 600 grams through microencapsulation process of 0.0080mm:Eu 2+ , Dy 3+ Luminescent materials and 100 grams of reflective glass beads wrapped in microcapsules and 3 grams of silane coupling agent 550 are added and stirred evenly. After the temperature drops, crush and sieve to obtain a luminescent and reflective layer coated on the surface of quartz sand The granular material B. Put the obtained material into the mold and form it into a luminous permeable brick with an initial brightness of 12cd / m 2 , 0.015cd / m after 10 hours 2 . CaSrS in this embodiment:Eu 2+ , Dy 3+ The light-emitting material is a sulfide-based light-storage type self-luminous material. See Table 2 for the comparison of its performance indi...

Embodiment 3

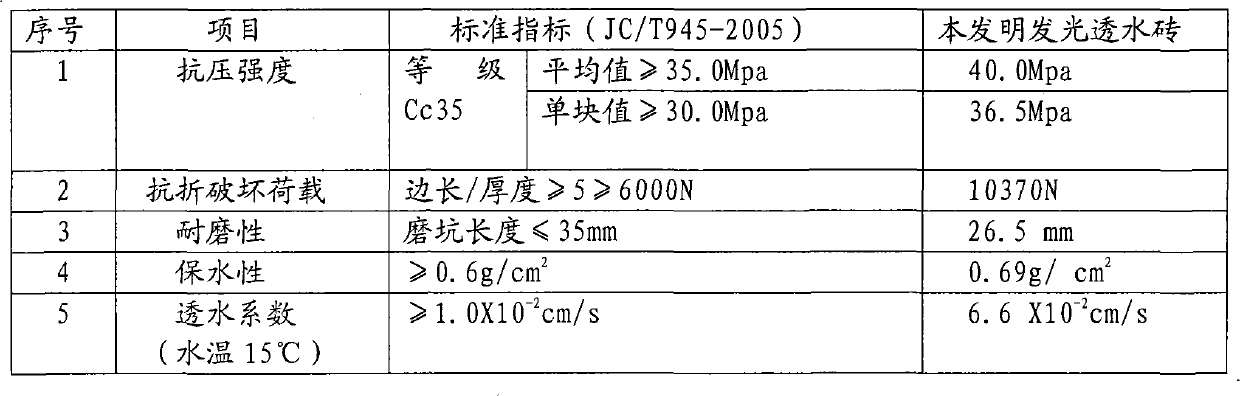

[0021]Take 15 kg of quartz sand with a particle size of 0.2-0.4mm, heat it to 260°C, and then add the pre-mixed mixture of the following materials, which is 600 grams of 70% 650 polyester solution and 560 grams of 75% HDI Biuret solution, 340 grams of hydrophilic epoxy resin, 5 grams of silane coupling agent 550, 0.6 grams of light stabilizer UV-327, 0.9 grams of antioxidant 1222, 1.8 grams of zinc naphthenate, as a chain extender and cross-linking agent 20 grams of trimethylolpropane of joint agent, 15 grams of methyl ethyl ketone as urethane grade solvent, particle diameter is the SrAl of 0.1mm 2 o 4 :Eu 2+ , Dy 3+ Add 500 grams of luminescent material, stir evenly after adding, crush and sieve after the temperature is lowered, and obtain granular material C with a luminescent layer coated on the surface of quartz sand. Put the obtained material into a mold and form it into a luminous permeable brick. The luminous brick emits yellow-green light, and its initial brightness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com