Composite gel anti-fire extinguishing material for coal seam fire control

A composite gel and fire-fighting technology, which is applied in the field of composite gel materials, can solve the problems of insufficient filling of cracks, accelerated coal-oxygen composite speed, and poor air blocking effect, so as to reduce the amount of loess and improve the wall adhesion. , the effect of reducing the loss of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

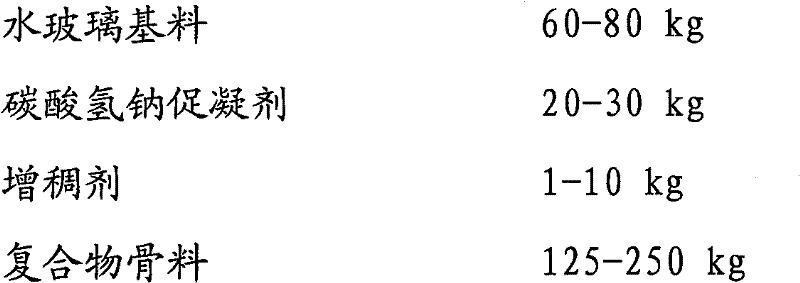

[0025] Composite gel fire extinguishing material, the main components are shown in Table 1. The loess is dried, ground, and sieved, and then mixed with super absorbent mineral clay, thickener, and sodium bicarbonate coagulant according to the ratio in Table 1. Mix evenly in the medium to obtain a solid mixture; then fully stir the water glass base material, water and the solid mixture according to the ratio in Table 1 to make a slurry.

[0026] Table 1 raw materials and dosage (unit: kilogram)

[0027] Example

1

Example

2

Example

3

Example

4

Example

5

Example

6

water glass

60

74

80

70

65

60

20

21.5

30

27

21

25

Sodium polyacrylate

10

0.5

5

2

5

3

5

Methylcellulose

0.5

3

1

100

...

Embodiment 2、3

[0033] For Embodiments 2 and 3, the present invention adopts a pipe network type large-flow glue injection process, utilizes the existing ground grouting fire extinguishing system of the coal mine, realizes large-flow transportation of gel fire extinguishing materials, and finally realizes the implementation of large-area fire extinguishing in mines. The colloid injection equipment adopts ZM-5 / 18N colloid mud injection machine, which can be used alone or in conjunction with the ground grouting system to quickly eliminate large-scale mine fires.

[0034] The composite gels prepared in the above examples all have good properties, and the fire extinguishing effect is very ideal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com