Water sealing consolidation equipment of cast-in-place pile soil body and construction technology thereof

A cast-in-place pile and water-stop technology, which is applied in soil protection, sheet pile wall, infrastructure engineering and other directions, can solve the problems of difficult to guarantee construction quality and low construction efficiency, so as to ensure the quality of concrete pouring, reduce construction difficulty and ensure The effect of excavation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

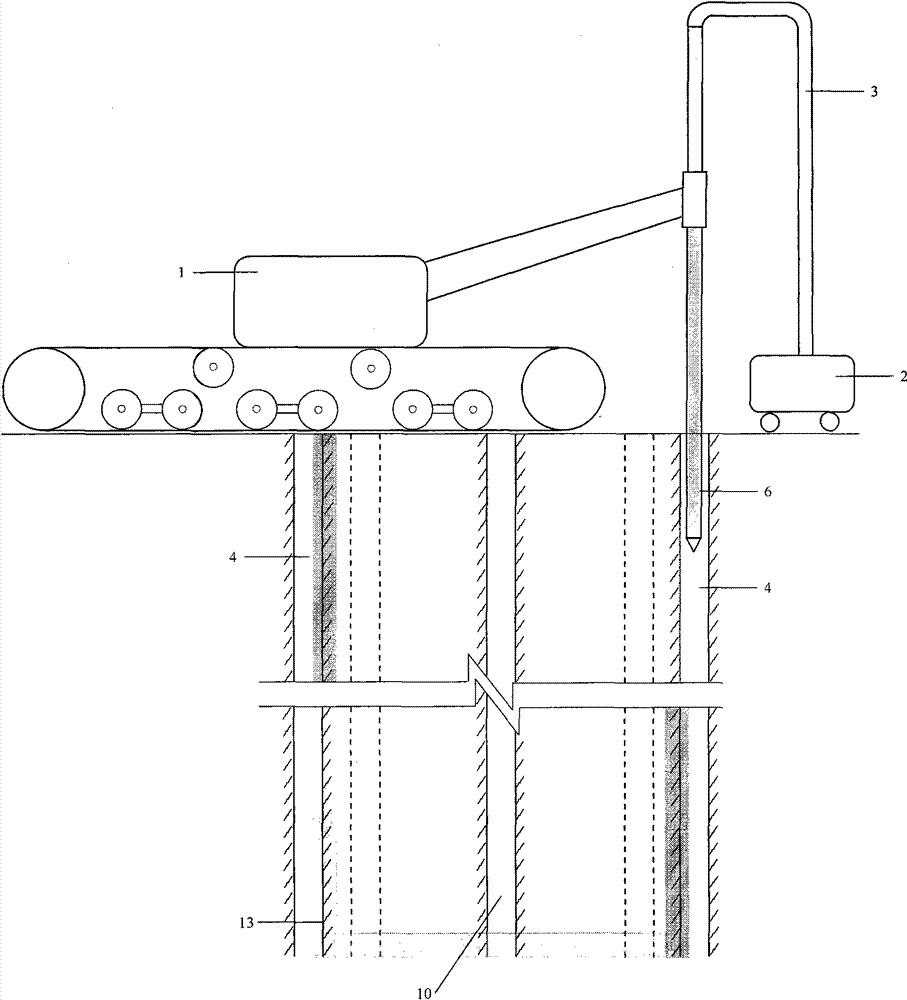

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

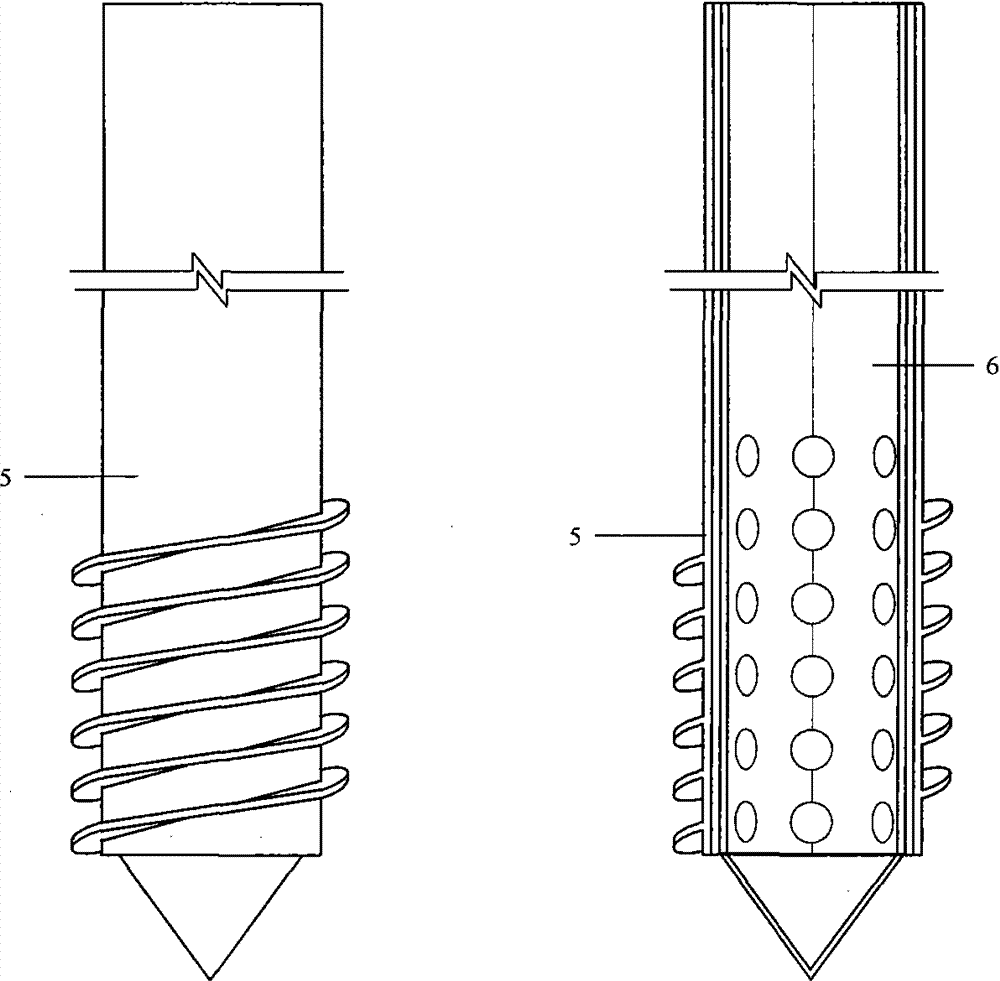

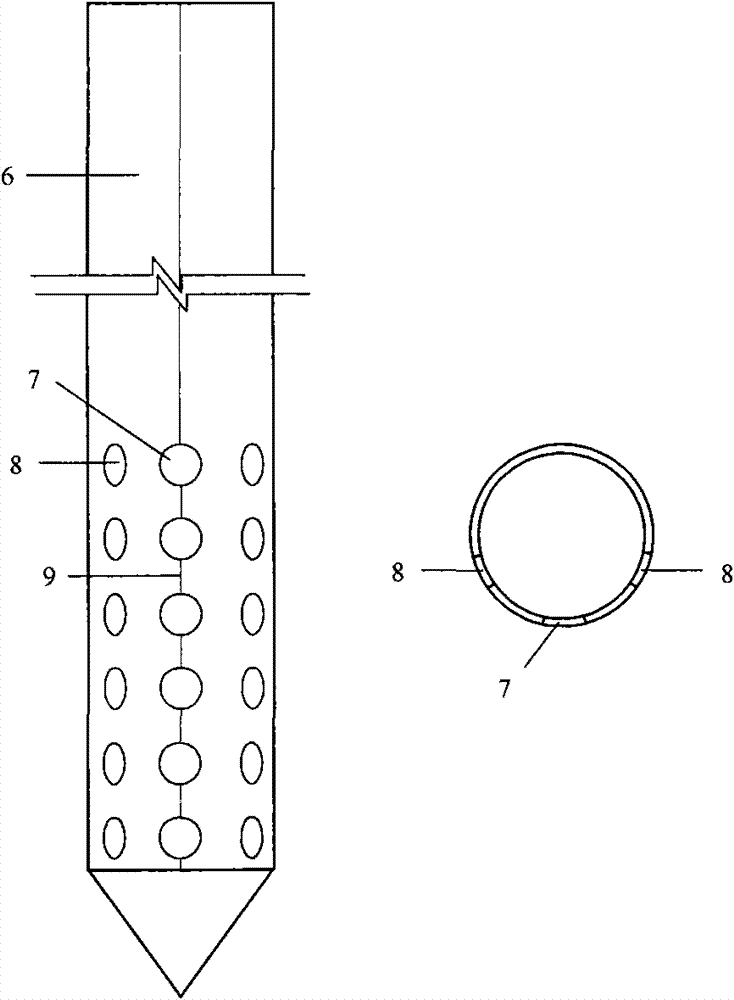

[0026] Depend on Figure 1-7 It can be seen that the concentric circle of the cast-in-situ pile to be excavated is measured first, and its diameter is 200 mm larger than the diameter of the cast-in-place pile, and then the circumscribed regular octagon of the circle is measured and released, and each apex of the regular octagon is used as the center of the circle. Φ42 geological drill pipe 5, drill eight pile side grouting holes 4, the pile side grouting holes 4 are 200mm deeper than cast-in-place piles, the geological drill pipe is also used as casing, and a whole Φ38 pile side grouting pipe is set inside the geological drill pipe 5 6. When the pile side grouting hole 4 is drilled to the design depth, adjust the angle of the pile side grouting pipe 6 so that the radial hole midline 9 on the pile side grouting pipe wall is right against the center of the cast-in-place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com