High-rise and super high-rise composite frame structure system with bilateral supports

A hybrid structure, super high-rise technology, applied in the direction of building structure, construction, etc., can solve the problems of incompatibility with high-rise/super high-rise buildings, poor lateral and torsional stiffness, weak earthquake resistance, etc., to achieve easy connection, The effect of solving stiffness problems and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

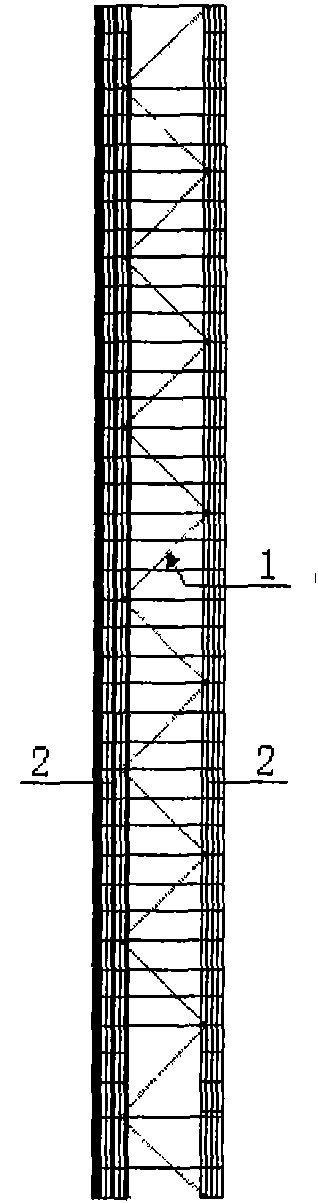

[0019] Such as figure 1 As shown, in this embodiment, the short direction of the building is a single-span frame structure, and the long direction is a multi-span frame structure. Steel supports 1 are arranged at both ends of the short direction of the building. Steel supports 1 and steel reinforced concrete columns / piers 2 at both ends The steel frame connection inside, the steel support 1, the steel reinforced concrete column / pier 2, and the steel reinforced concrete beam form a space truss system.

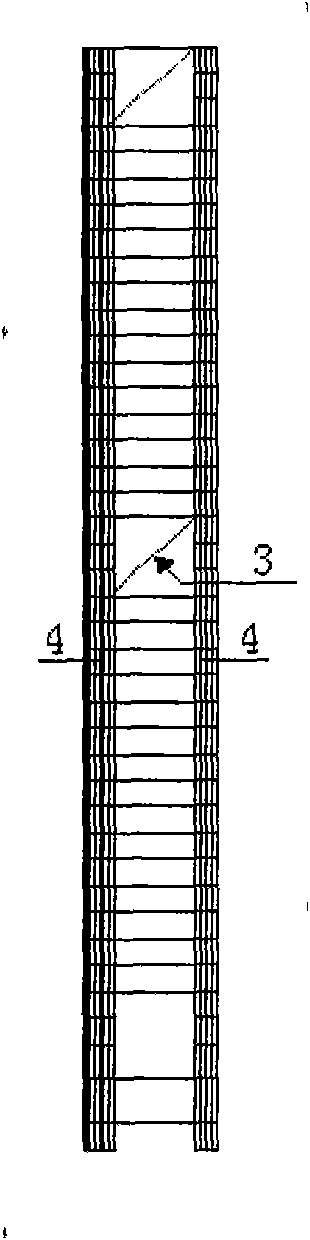

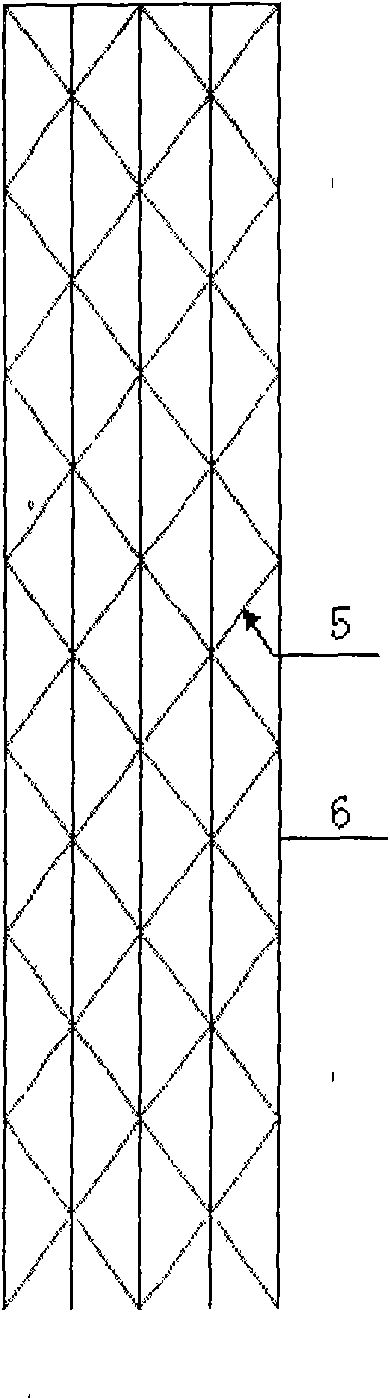

[0020] Such as figure 2 As shown, a reinforced layer is set at the middle and top of the building at the same time, and on the reinforced layer, several steel supports 3 are arranged along the short direction of the building, and the steel supports 3 are connected with the steel frames in the steel-reinforced concrete columns / piers 4 at corresponding positions. The steel support 3 forms a space truss system with the corresponding steel reinforced concrete column / pier 4 and ste...

specific Embodiment 2

[0024] The characteristics of specific embodiment 2 are: in the building, only a reinforcing layer is set in the middle of the building, and several steel supports 3 are set along the short direction of the building, and the steel supports 3 and steel reinforced concrete columns / piers 4 at corresponding positions The inner steel frame is connected, and the steel support 3 forms a space truss system with the steel reinforced concrete column / pier 4 and the steel reinforced concrete beam at the corresponding position; the cross section of the steel support is I-shaped or box-shaped. The height of the building is 70 meters, and the ratio of the height to the width of the building is 5.

specific Embodiment 3

[0025] The characteristics of specific embodiment 3 are: the height of the building is 180 meters, and the ratio of the height to the width of the building is 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com