Integrated light source measuring apparatus

A technology of measuring device and light source, applied in the direction of measuring device, optical radiation measurement, device with multiple detectors, etc., can solve the problems of shortening, decreased sensitivity, easy wear life of camera shutter, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be pointed out that the interpretation of terms or words in this specification and claims is not limited to the common understanding and the meaning in the dictionary. A principle that should be explained is that the inventor can properly define For the concepts of terms, their explanations should adopt the meanings and concepts consistent with the technical status of the present invention. Therefore, it should be understood that the embodiments described in this specification and the structures shown in the drawings are only preferred embodiments of the present invention, not all technical ideas of the present invention, which may also be the corresponding equivalents and modified examples of the present application .

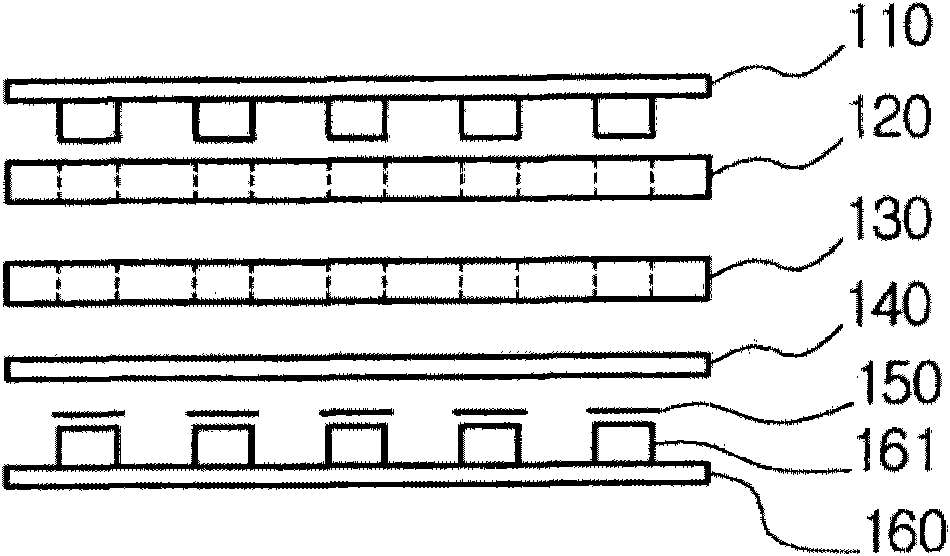

[0026] figure 1 is a cross-sectional view of the integrated light source measurement system according to the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com