Light-emitting module with high heat conduction and light guide functions and devices applying same

A technology for light-emitting modules and light-emitting devices, which can be applied to identification devices, semiconductor devices, instruments, etc., can solve problems such as inconvenience and lack, and achieve the effects of reducing costs, improving yield, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

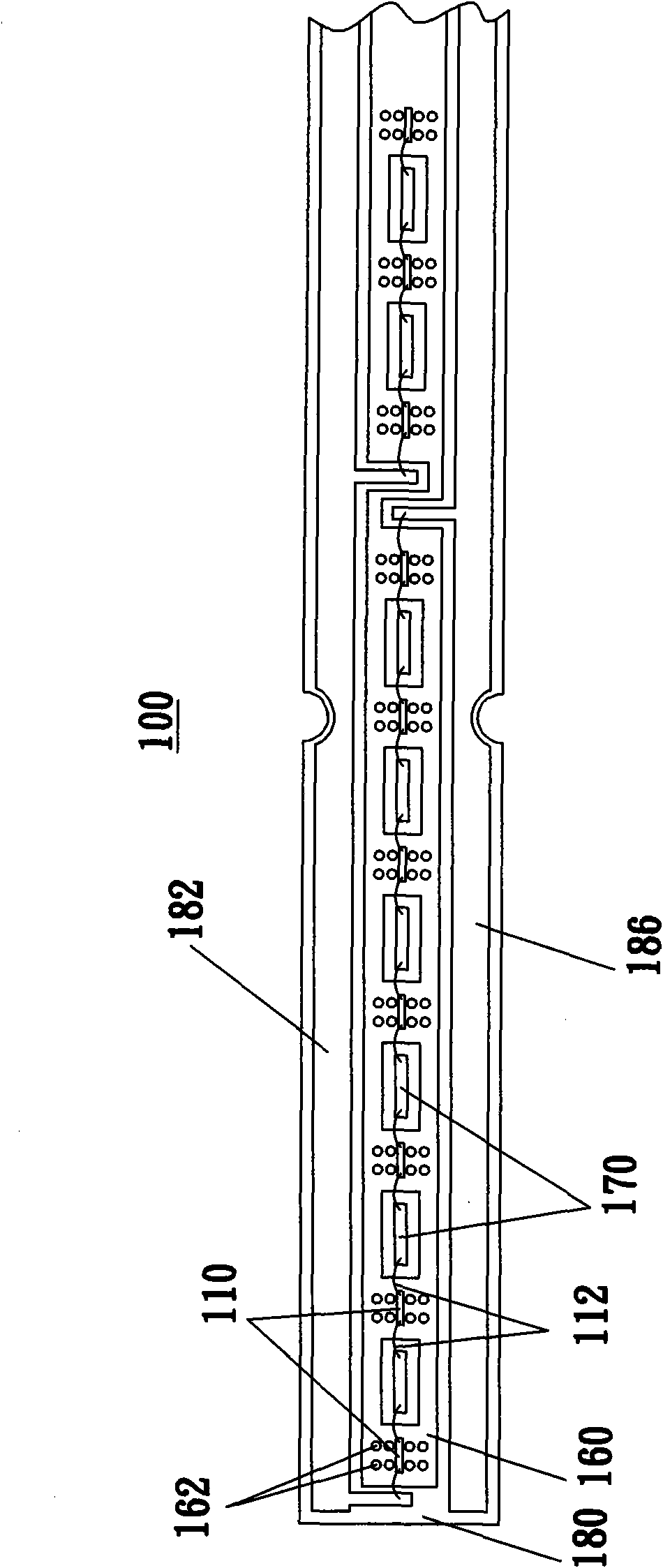

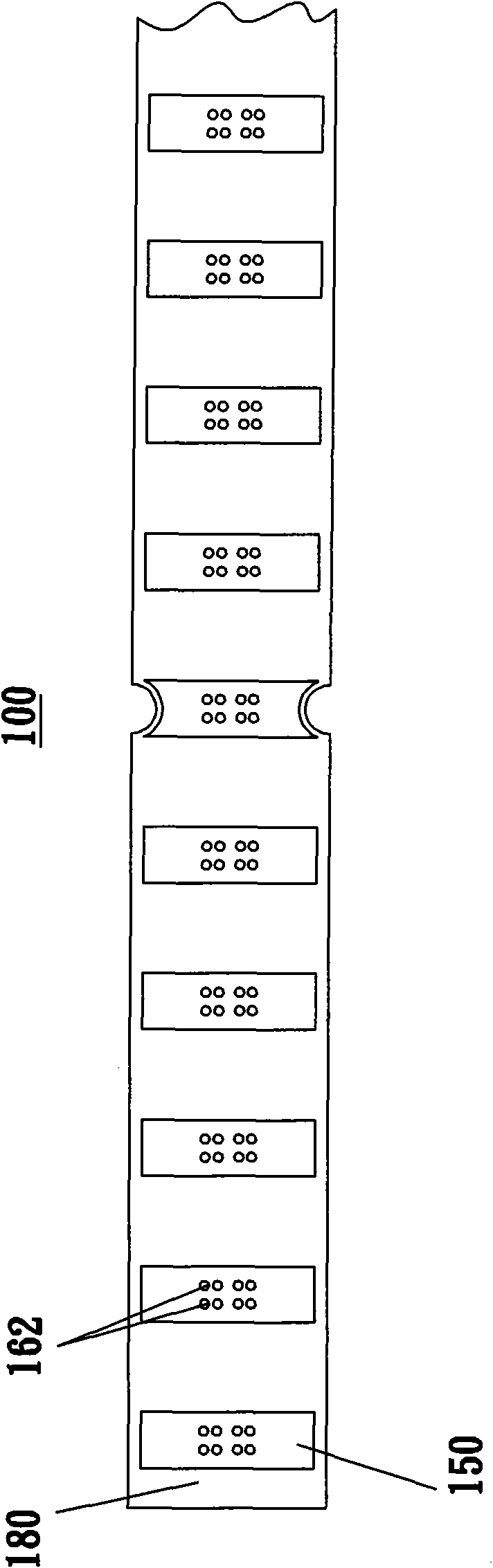

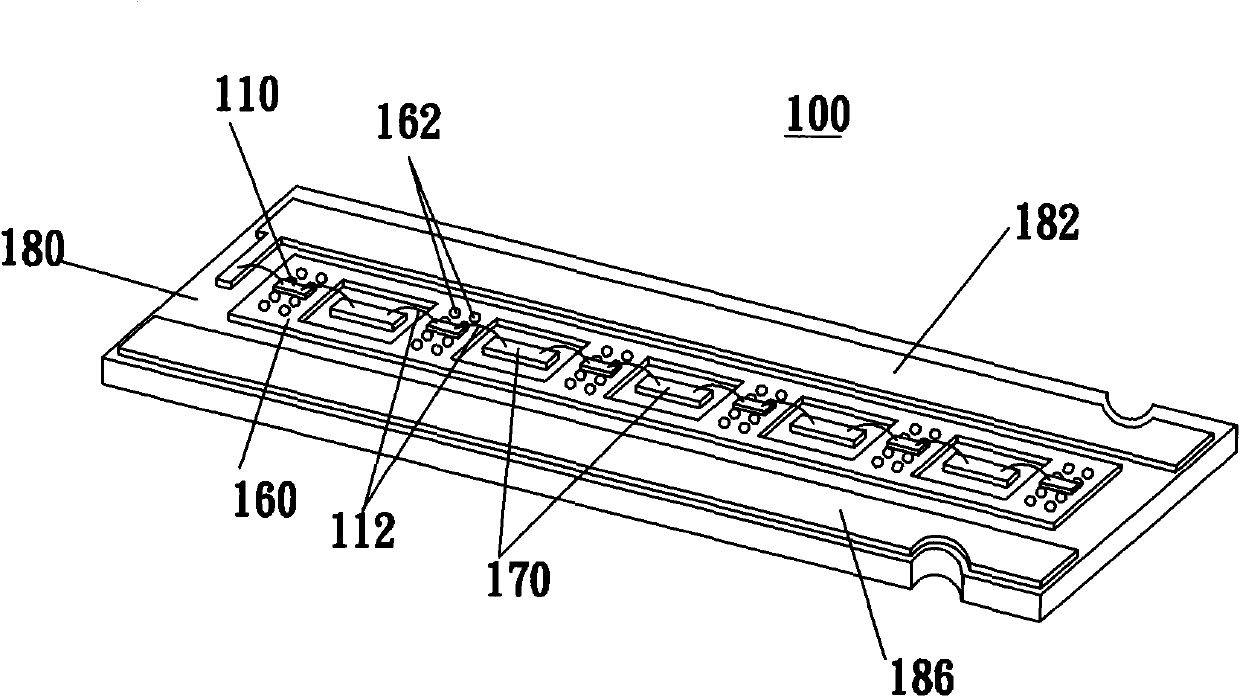

[0035] Please also refer to Figure 1 to Figure 5 , which respectively show different views of the first embodiment of the lighting module 100 of the present invention. The light emitting module includes a plurality of light emitting chips 110 and a conductive substrate. The conductive substrate includes a base material 180 , a chip pad 160 , a wire pad 170 and a heat conduction layer 150 .

[0036] The base material 180 is formed with a first surface (i.e. figure 1 the front side shown in , not labeled) and the second side opposite the first side (i.e. figure 2 The back side shown in , not labeled), is provided with conductive traces 182, 186 on the first side. Wherein the conductive track 182 is a positive conductive track, and the conductive track 186 is a negative conductive track. Of course, the positive and negative poles of the above-mentioned conductive traces can be adjusted as required, or combined with the chip pad 160 to meet the restrictions of different typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com