Tobacco stem expanding method and equipment using low-pressure steam as medium

A steam medium and tobacco stem technology, applied in the field of tobacco stem expansion, can solve the problems of difficulty in achieving satisfactory expansion effect, poor expansion uniformity, uneven expansion of cut stems, etc., and achieves reduced equipment configuration costs, high filling rate, and reduced manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

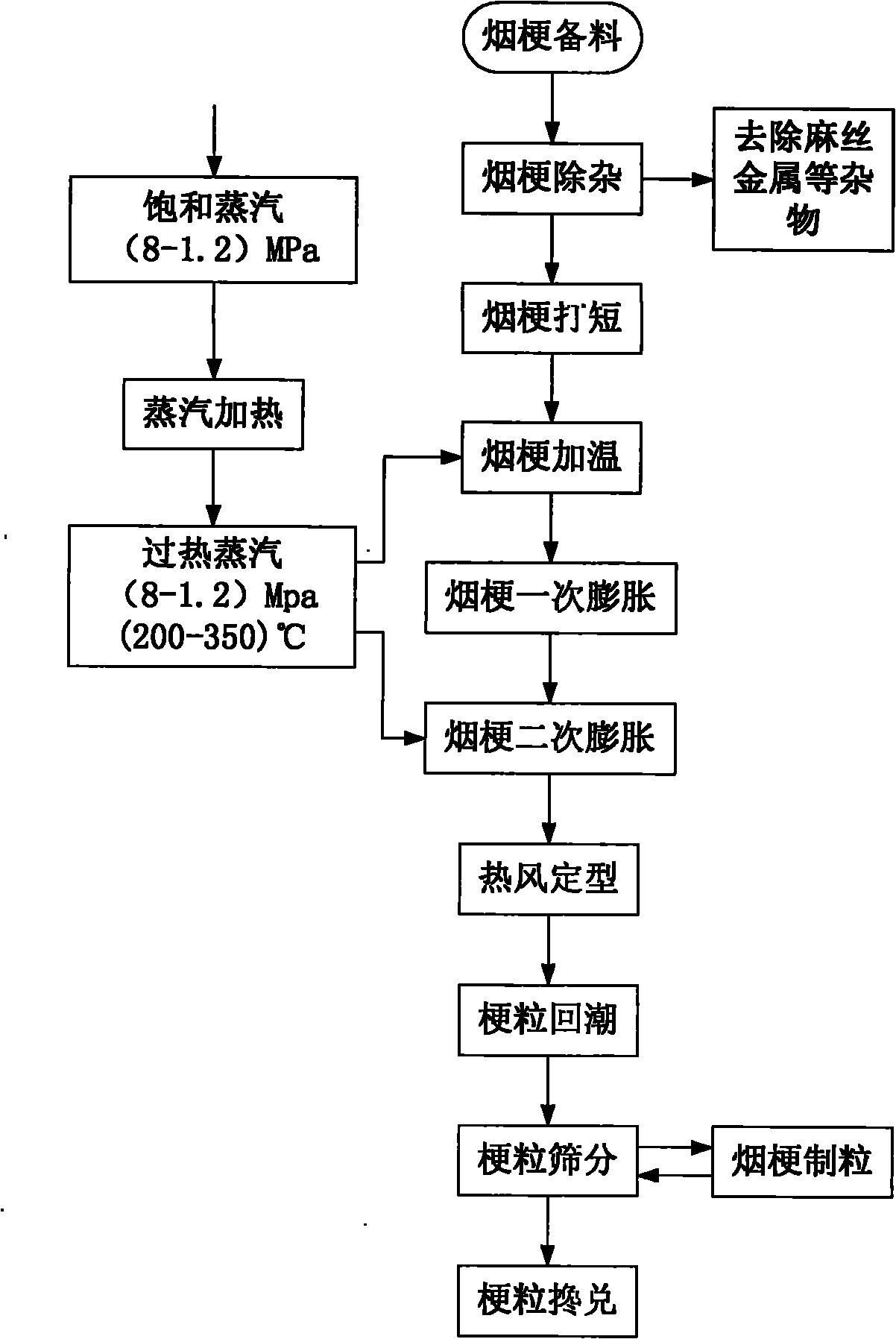

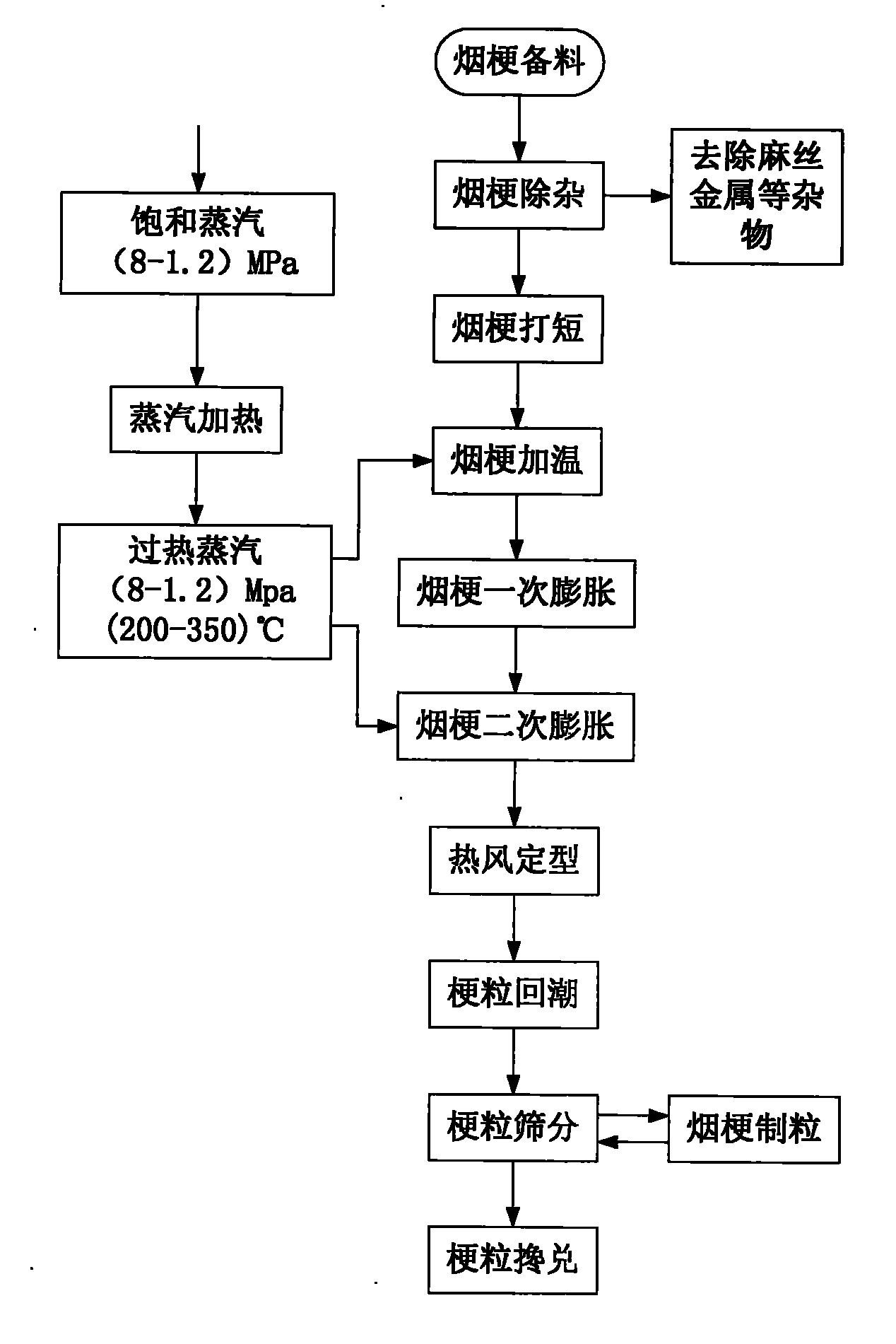

[0027] Such as figure 1 As shown, the preferred tobacco stem expansion method of the present invention may include the following process in turn: after the tobacco stems are prepared, remove hemp, metal and other impurities in the tobacco stems by removing impurities; then shorten the tobacco stems to 5-30mm Short stems, shortening the tobacco stems is beneficial to the heat transfer in the subsequent heating process of the tobacco stems, and is also conducive to the explosion of the tobacco stems into stem grains during the expansion process of the tobacco stems; after shortening, the tobacco stems are heated, and the heating medium is a pressure of 0.8 -1.2MPa, superheated steam with a temperature of 200-350°C; the mixed tobacco stem and steam mixture is released into the normal pressure environment through the rotation of the steam-lock rotor to implement the primary expansion of the tobacco stem; after the primary expansion, the tobacco stem enters the Venturi tube, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com