Bag-type dust remover for dry purifying system

A bag dust collector and dry purification technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem that the adsorbent cannot be fully recycled, the equipment occupies a large area, and the service life of the filter bag is short, etc. problems, to achieve the effect of improving the overall purification efficiency, reducing the cutting process and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

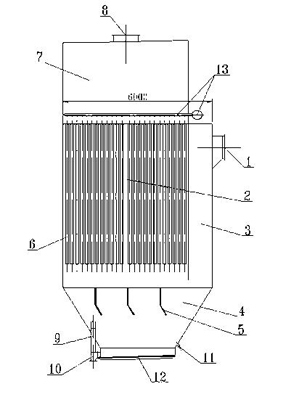

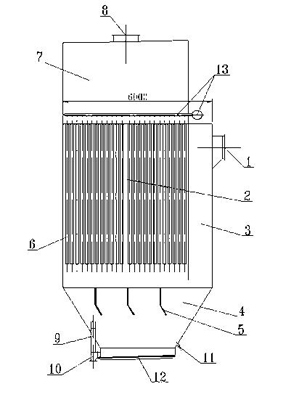

[0013] Embodiment of the present invention: the present invention is composed of ash hopper 4, middle box 2 and upper box 7 which are connected in sequence. The width of middle box 2 is 6m, and the length of the box is 4-5.5m. The air inlet 1 is connected to the body 2, and a filter bag 6 is suspended inside it. The diameter of the filter bag 6 is Ф127~140mm, and the length is 6m. And blowback system 13, one side in the middle box body 2 is provided with an air flow reaction channel 3 communicated with the air inlet 1, and the air flow reaction channel 3 can be made by welding a partition plate in the middle box body 2 to form The outlet of the air flow reaction channel 3 is opposite to the opening of the ash hopper 1, a deflector 5 is provided in the hollow part of the ash hopper 4, and an overflow pipe 9 for ash discharge and a slag discharge pipe are provided on the side of the ash hopper 4. The empty emptying port 10 and the circulating material port 11, the circulating ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com