Small-hole grinding tool for correcting hole diameter

A grinding tool and aperture technology, applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve the problem of customizing multiple tools, and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

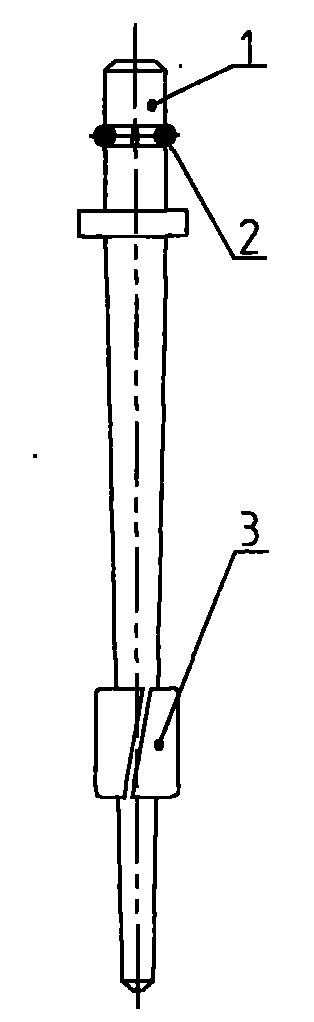

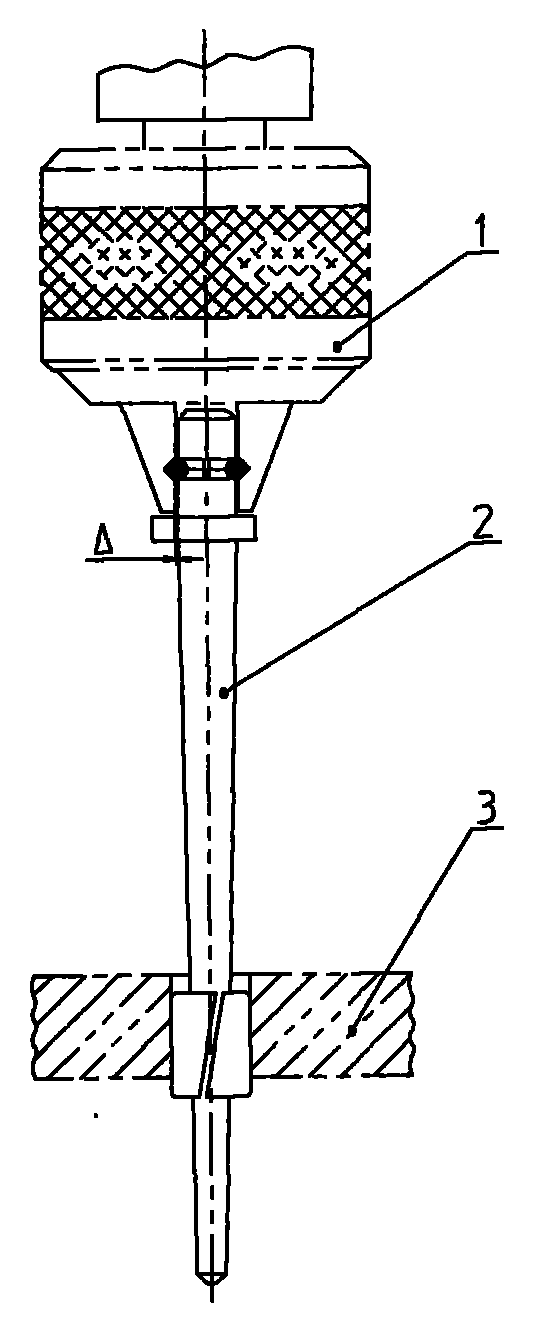

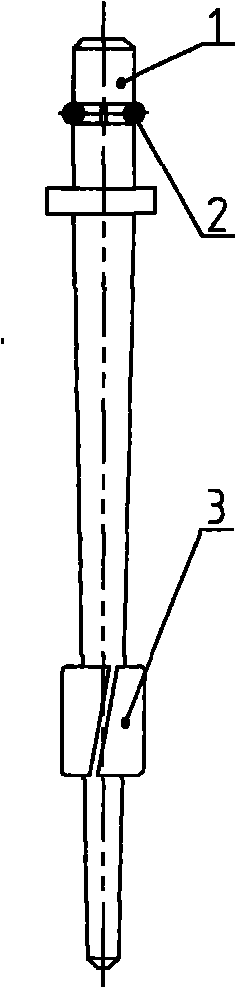

[0019] see figure 1 , the small hole grinding tool used to correct the aperture includes a grinding mandrel 1, the grinding mandrel is a conical shaft, and its large diameter end is a clamping part, and the clamping part is radially provided with a ring groove, and an opening is clamped in the ring groove The traveler 2; the other side is the working part, and the working part is equipped with an opening grinding sleeve 3. The taper of the working part of the grinding mandrel 1 and the taper of the inner hole of the open grinding sleeve 3 are both 1:50 degrees, the wall thickness of the open grinding sleeve is 0.8-1.2 mm, and the opening groove is an oblique opening groove at an angle with the axis; The cross-section of part of the annular groove is semicircular.

[0020] When in use, put the end of the taper mandrel with the open traveler 2 into the drill chuck of the drill press, put the open traveler into the ring groove of the clamping part of the drill chuck during clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com