High-pressure sealing driver of oil-extracting screw pump

A high-pressure sealing and driver technology, used in pumps, machines/engines, pumps with flexible working elements, etc., can solve problems such as being unable to withstand high pressure at the wellhead, and achieve long life, prolong life, and improve lubrication conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

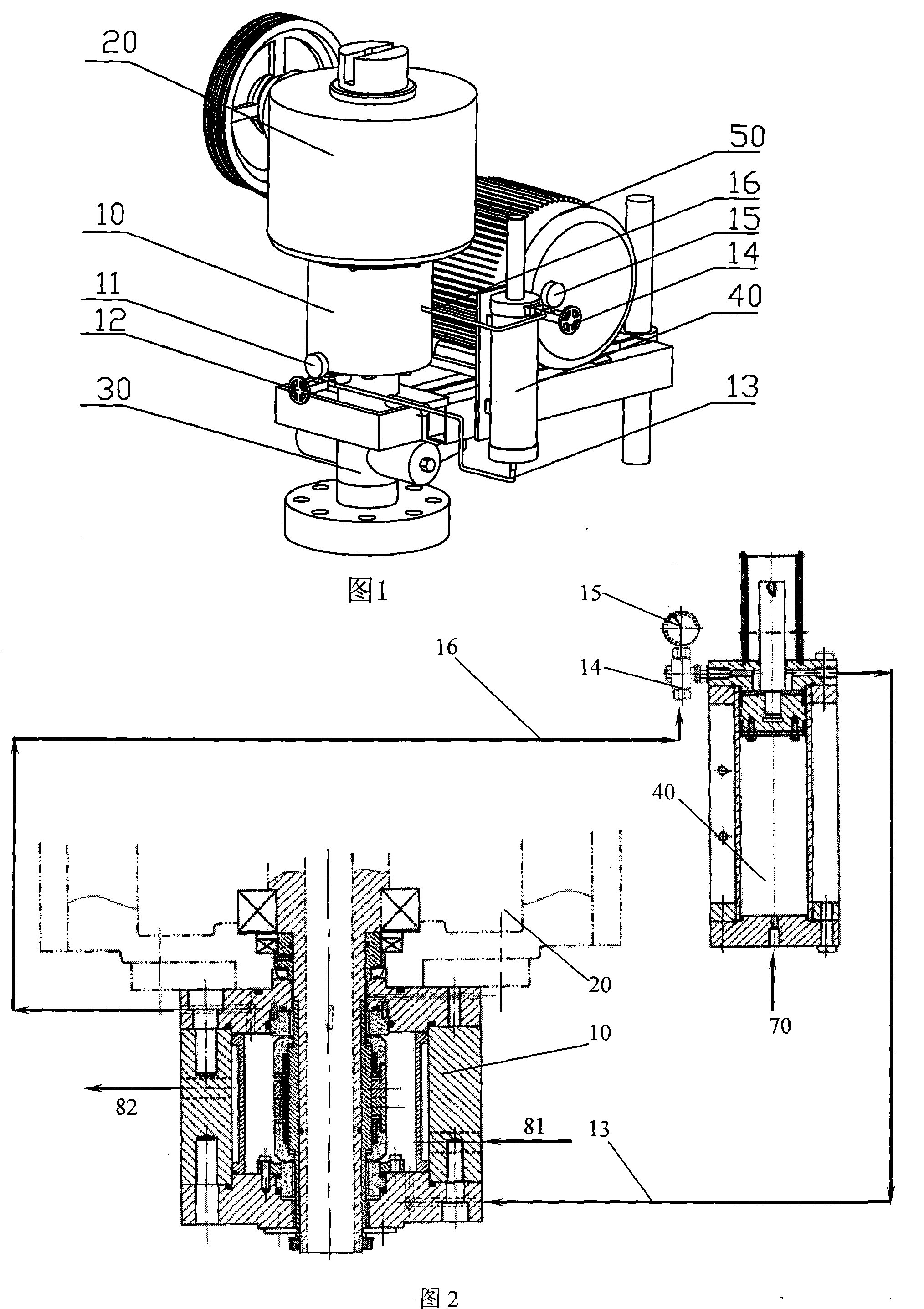

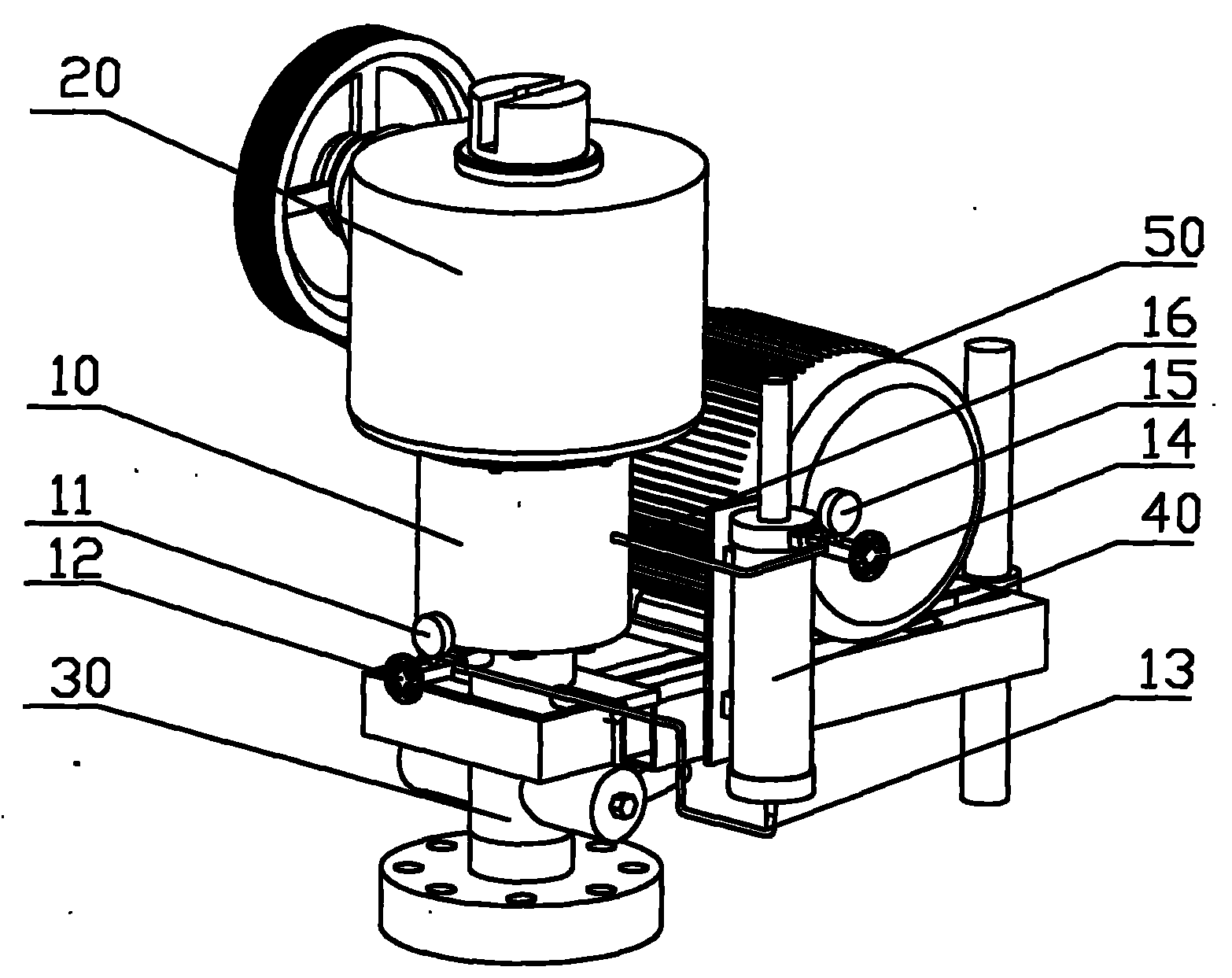

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] Main parts and details of the present invention: 10 high-pressure double-face mechanical seal, 11 input pressure gauge, 12 input valve, 13 pressure input pipeline, 14 output valve, 15 output pressure gauge, 16 pressure output pipeline, 20 deceleration Box, 30 bracket, 40 mechanical seal auxiliary booster device, 50 motor, 70 well pressure inlet, 81 coolant inlet, 82 coolant outlet.

[0012] Usually, the high-pressure sealed driver of the oil production screw pump is fixedly installed on the flange of the wellhead Christmas tree. The power of the motor is transmitted to the polished rod through the pulley, the reduction box and the polished rod clamp, and then transmitted to the downhole through the polished rod that runs through the main shaft of the drive. The high-pressure sealing driver of the screw pump for oil production o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com