Off-line filter-cell chemically-cleaning device

A filter element and off-line technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as difficult control of cleaning conditions and complicated cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

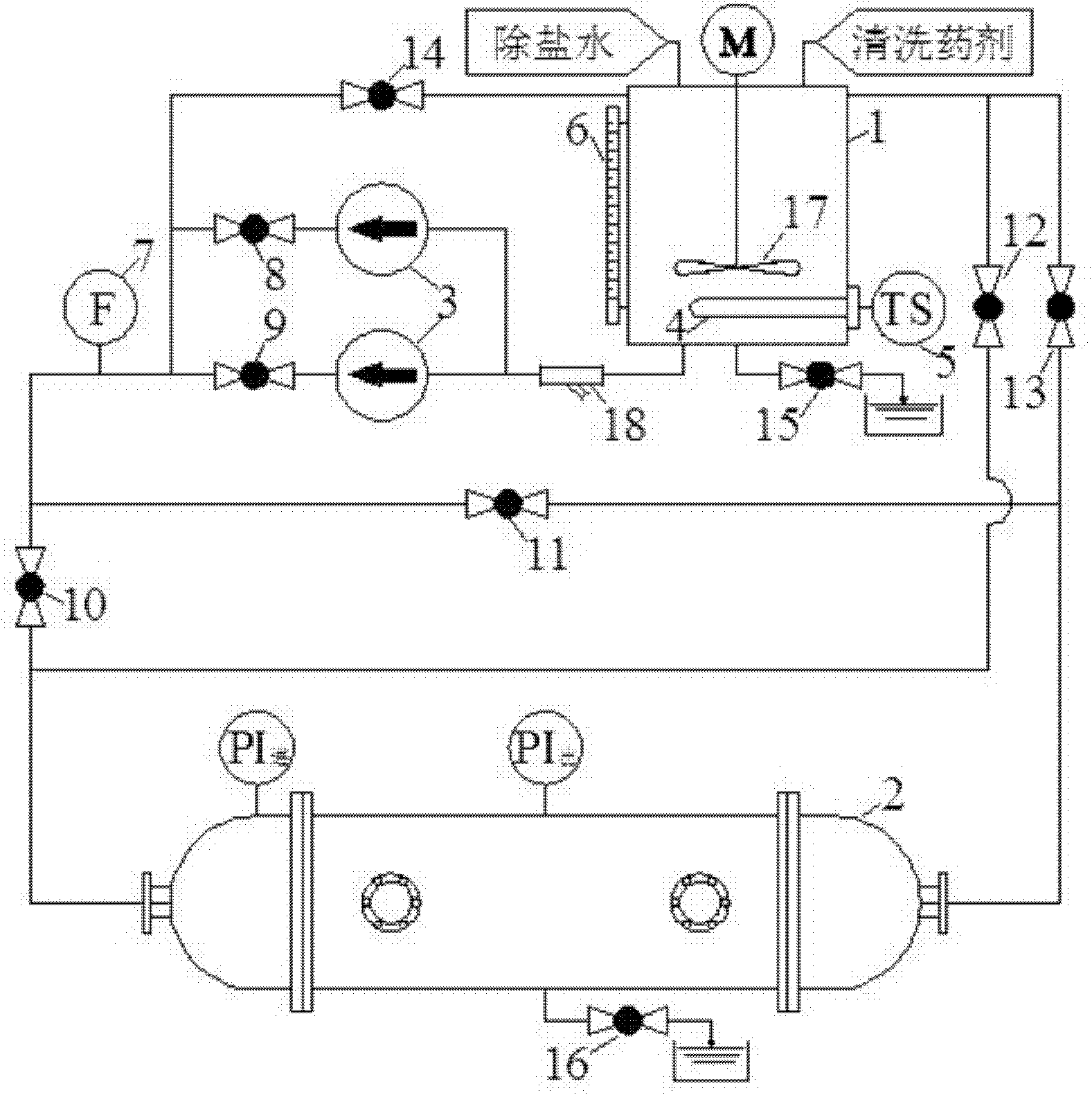

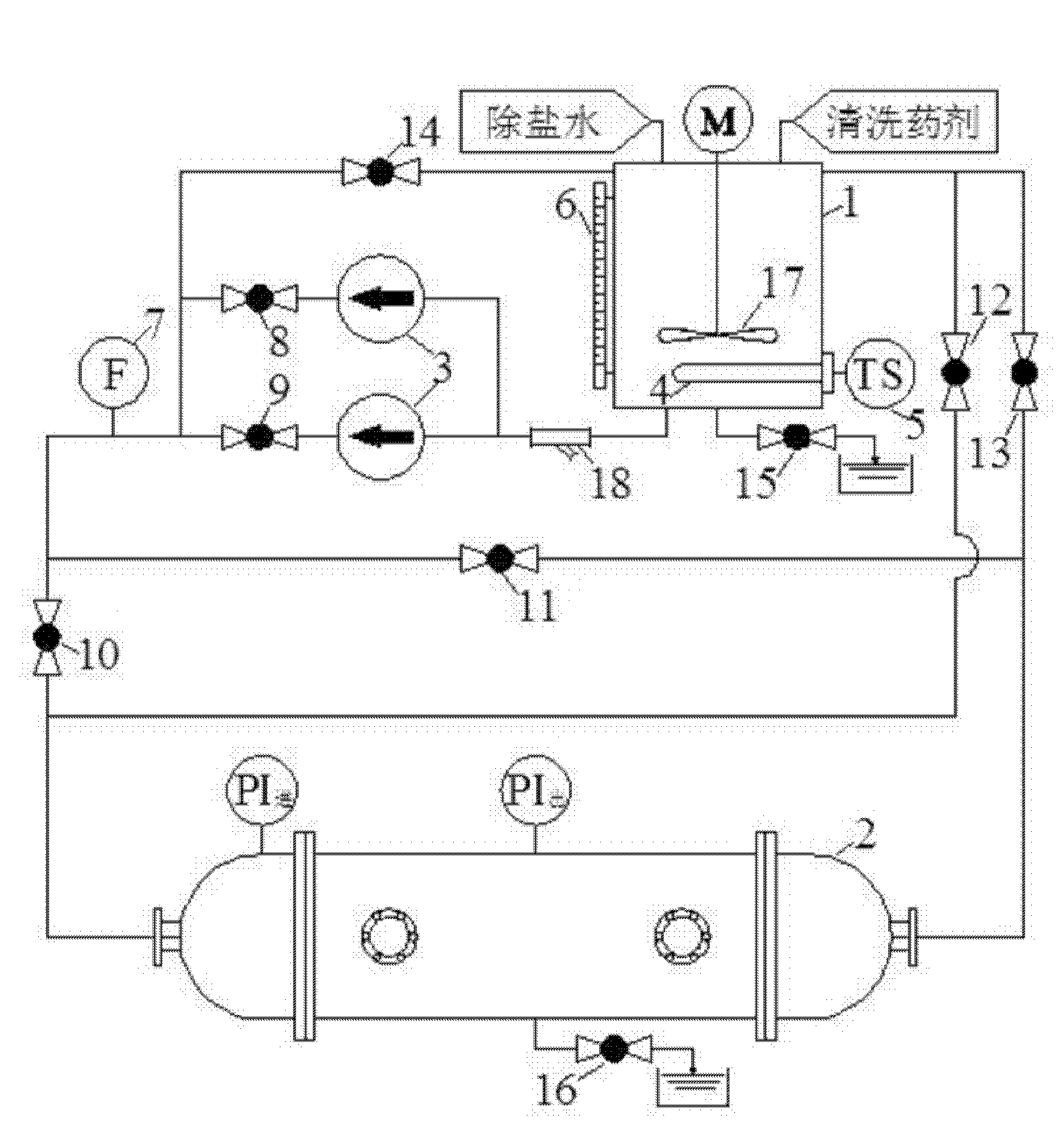

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] see figure 1 , the present invention includes a solution tank 1 and a horizontal cleaning tank 2 made of anti-corrosion stainless steel, the solution tank 1 communicates with the horizontal cleaning tank 2 through pipelines, and the inside of the horizontal cleaning tank 2 is installed with a filter element to be cleaned. The detachable splint can install 30-150 contaminated filter elements at a time. By replacing different types of splints, different types of filter elements can be cleaned, and there are pressure gauges PI inlet and outlet respectively at the horizontal cleaning tank 2 inlet and outlet. , PI out, solution tank 1 and horizontal cleaning tank 2 are provided with Y-shaped filter 18, water pump 3, flowmeter 7, first valve 10 and second valve 11 in turn on the pipeline that is connected with horizontal cleaning tank 2, and water pump 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com