One-step forming forging mould of elongated forging with upsetting ratio bigger than 3

A technology of upsetting ratio and forming die, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

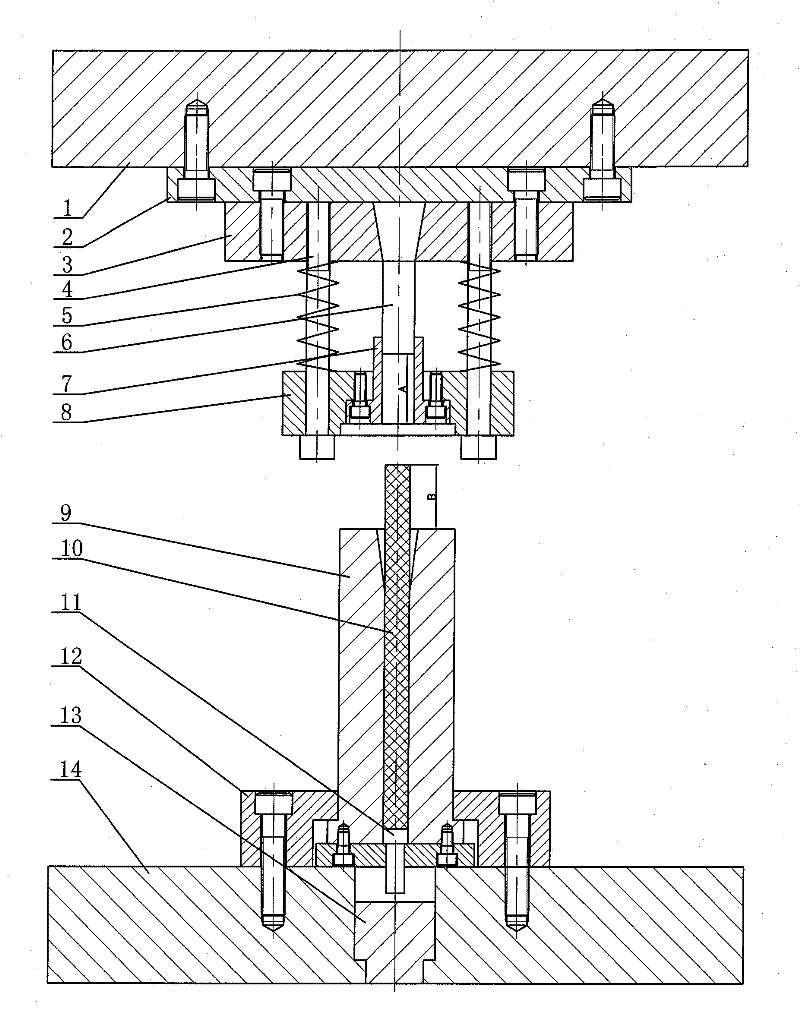

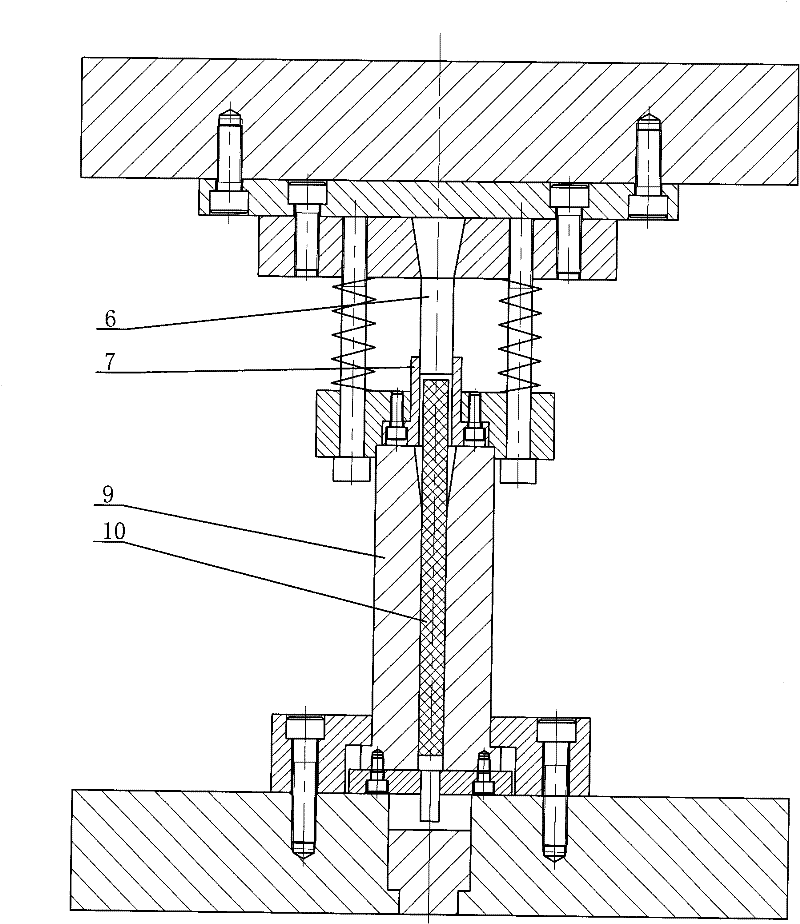

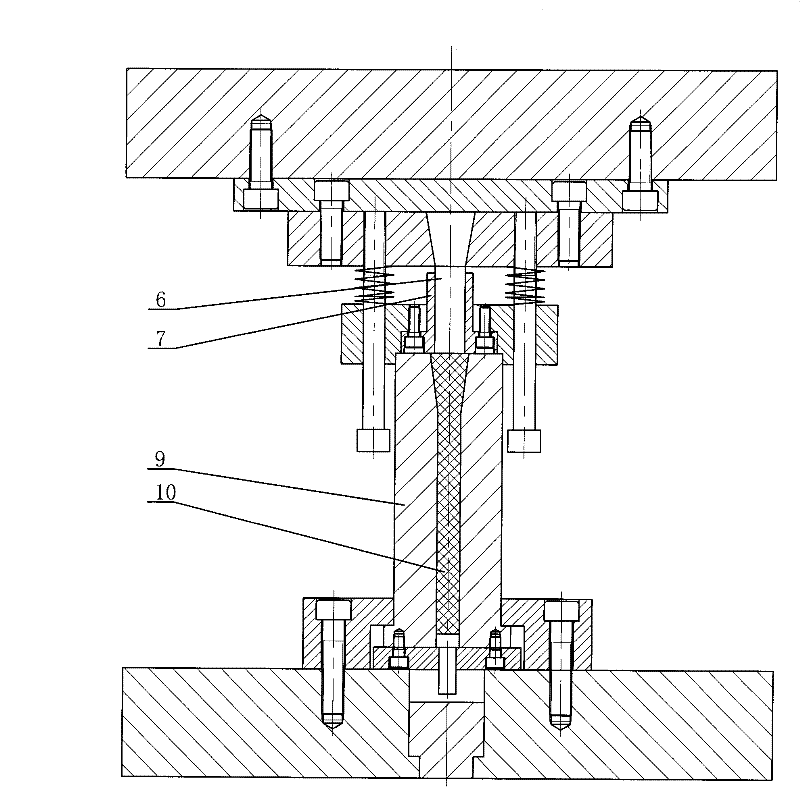

[0014] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0015] Refer to attached figure 1 , this kind of die forging die includes an upper die and a lower die 9, the upper die includes a fixedly connected upper template 1, a punch pressing plate 2 and a punch fixing plate 3, and the punch 6 is fixed on the upper die through the punch fixing plate 3 , the outer circle of the punch 6 is provided with a movable sheath 7, the sheath 7 is provided with the inner hole of the slender forging 10 that exposes the cavity of the lower die 9, the inner hole of the sheath 7 is connected with the punch The outer circle of 6 is sliding fit, the fit gap is 0.02mm to 0.03mm, the sheath 7 is fixedly connected with the sheath fixing ring 8, the sheath fixing ring 8 can slide up and down and is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com