Process for casting oil distribution disc of vane pump

A technology of casting blades and oil distribution plates, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of affecting the smoothness of oil passages, increasing the noise of vane pumps, and the number of molds, etc., achieving significant economic benefits and social benefits Benefits, improve product quality, improve the effect of casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

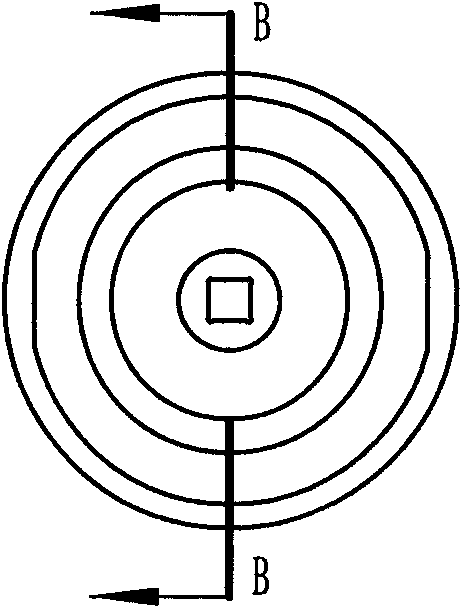

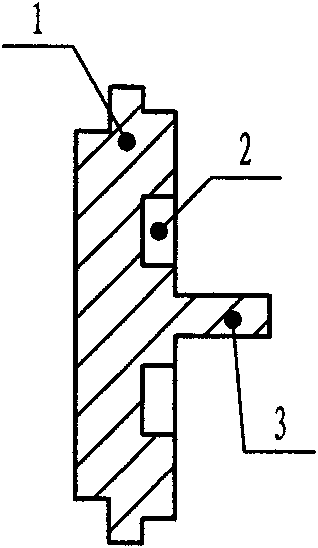

[0043] Embodiment 1: This embodiment is the casting of PFX21 oil distribution plate, including process design, mold design and manufacture, core making, sand core assembly, modeling, pouring, and sand cleaning. This embodiment consists of 1#, 2#, and 3# sand The core and the 145 molding machine plate are composed, and the specific steps are as follows:

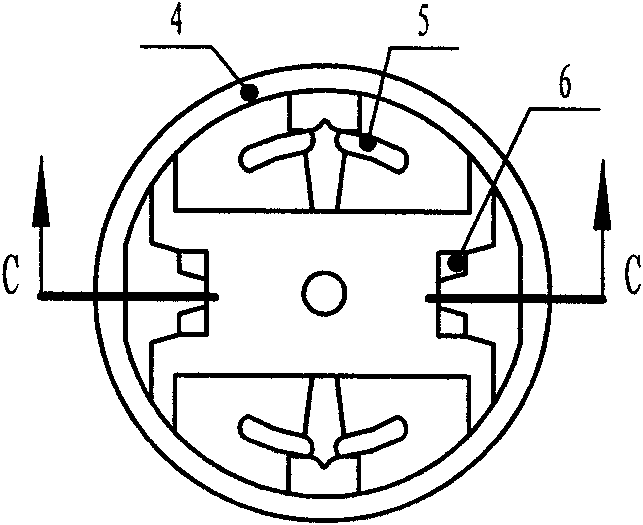

[0044] 1. Process design: Determine the process plan, use coated sand to make the core, and make a thin-shell sand core. All castings are made in the sand core, and the sand core is placed in the green mold sand cavity for pouring; design according to the part drawing casting process, Figure 9 As shown, the inner cavity of the oil passage of the part is conical, that is, one end of the oil passage has a larger aperture, and the other end has a smaller aperture (the factory term is called dovetail shape, that is, the shape of the sand core of the oil passage is dovetail shape, and one end of the sand core is wider. , the othe...

Embodiment 2

[0052] Embodiment 2: This embodiment is the casting method of PFX3-07 oil distribution plate. The process steps are the same as in Embodiment 1. The difference is that a total of 6 sand cores are required, that is, 1 main body sand core and 2 independent Dovetail sand core, 2 filling sand cores and 1 cover plate sand core, the shaft hole sand core and the main sand core are blown together, the two dovetail oil passages are made separately, and the independent dovetail sand core is bonded The sand filling agent is bonded to the chassis of the main sand core, and the sand filling sand core is composed of 2 small sand cores, which are molded with a 145 molding machine, with 4 pieces in one mold.

Embodiment 3

[0053] Embodiment 3: This embodiment is the casting method of PFX4-07 oil distribution plate. Its process steps are the same as in Embodiment 1. The difference is that a total of 6 sand cores are required, that is, 1 main body sand core and 2 independent Dovetail-shaped sand core, 2 independent ordinary oil passage sand cores and 1 cover plate sand core, the dovetail sand core is made separately and bonded to the cover plate sand core by adhesive, two ordinary oil passage sand cores They are independently blown and called independent ordinary oil channel sand cores, and are bonded to the cover plate sand cores by adhesives. They are molded with a 145 molding machine, and there are 4 pieces in one mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com