Composition for modifying wood, preparation method and application thereof

A wood modification and composition technology, which is applied in the direction of wood impregnation, impregnated wood, wood processing equipment, etc., can solve the problems of poor material, low density and surface hardness, and limited application range, etc., to achieve improved dimensional stability and energy saving Good, the effect of overcoming cracking and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

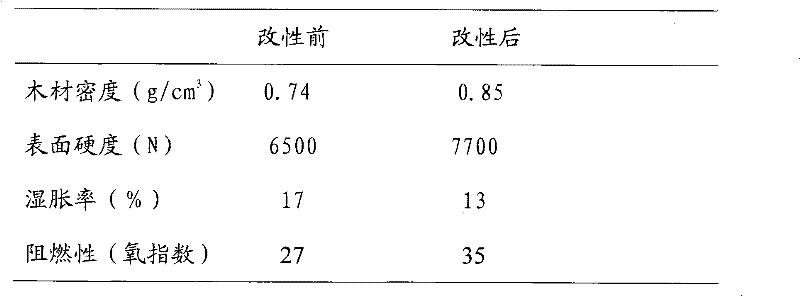

Embodiment 1

[0033] One, the preparation of composition for wood modification

[0034] Take each component (unit: Kg) phosphoric acid (content is 98%) by following weight: 253, urea (purity is 98%, industrial grade): 126, borax (industrial grade, purity 95%): 13, hydrogen phosphate Diammonium: 88, ammonium chloride: 13, water: 507; add the above-mentioned components into the reaction kettle, mix well at room temperature, adjust the pH value of the mixture to 5.0-6.0 with sodium hydroxide, and obtain the product.

[0035] 2. Application of composition for wood modification

[0036] (1) Put the eucalyptus wood to be treated into a pressurized impregnation tank and then vacuumize it, and inhale 2 / 3~3 / 4 of the present embodiment by weight under the vacuum condition of -0.09~-0.095MPa. The prepared wood modification composition;

[0037] (2) After the vacuum is released, pressurize and impregnate the wood with the rest of the wood modification composition under a pressure of 1.0-1.5 MPa for 3...

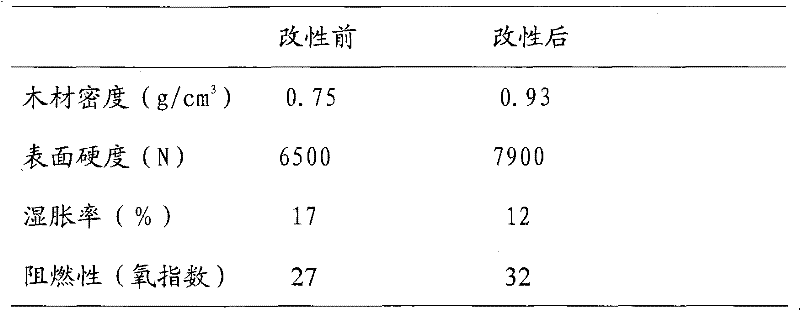

Embodiment 2

[0042] One, the preparation of composition for wood modification

[0043] Weigh each component by the following weight (unit: Kg) phosphoric acid (content is 98%): 250, acetylurea: 129, sodium borate crystal (industrial grade, purity 95%): 16, diammonium hydrogen phosphate: 85, chlorine Ammonium chloride: 13, water: 507; add the above-mentioned components into the reaction kettle, mix well at room temperature, adjust the pH value of the mixture to 5.0-6.0 with sodium hydroxide, and obtain the product.

[0044] 2. Application of composition for wood modification

[0045] (1) Put the eucalyptus wood to be treated into a pressurized impregnation tank and then vacuumize it, and inhale 2 / 3~3 / 4 of the present embodiment by weight under the vacuum condition of -0.09~-0.095MPa. The prepared wood modification composition;

[0046] (2) After the vacuum is released, pressurize and impregnate the wood with the rest of the wood modification composition under a pressure of 1.0-1.5 MPa for...

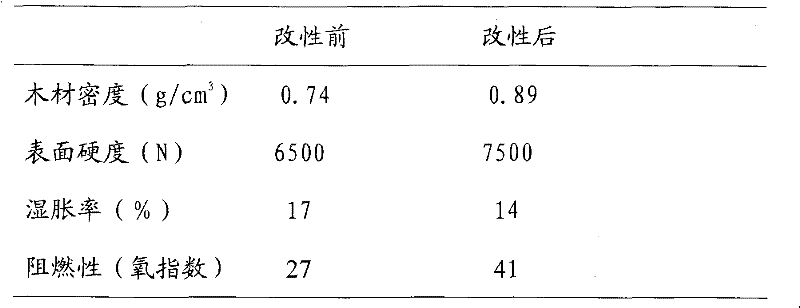

Embodiment 3

[0051] One, the preparation of composition for wood modification

[0052] Take each component (unit: Kg) phosphoric acid (content is 98%) by following weight: 253, triethylenetetramine: 120, borax (industrial grade, purity 95%): 19, diammonium hydrogen phosphate: 86, chlorine Ammonium chloride: 23, water: 497; add the above-mentioned components into the reaction kettle, mix well at room temperature, adjust the pH value of the mixture to 5.0-6.0 with sodium hydroxide, and obtain the product.

[0053] 2. Application of composition for wood modification

[0054] (1) Put the paulownia wood to be treated into a pressurized impregnation tank and then vacuumize it, and suck 2 / 3~3 / 4 parts by weight of the present embodiment under the vacuum condition of -0.09~-0.095MPa. The prepared wood modification composition;

[0055] (2) After the vacuum is released, pressurize and impregnate the wood with the rest of the wood modification composition under a pressure of 1.0-1.5 MPa for 3 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com