Crankless piston type stepless speed change engine and design method

A continuously variable and piston-type technology, applied to reciprocating piston engines, variable displacement engines, engine components, etc., can solve the problems of increasing its own weight and fuel consumption, complicated crankshaft processing technology, and large volume, etc., to reduce machining The effect of reducing cost, saving the crankshaft, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

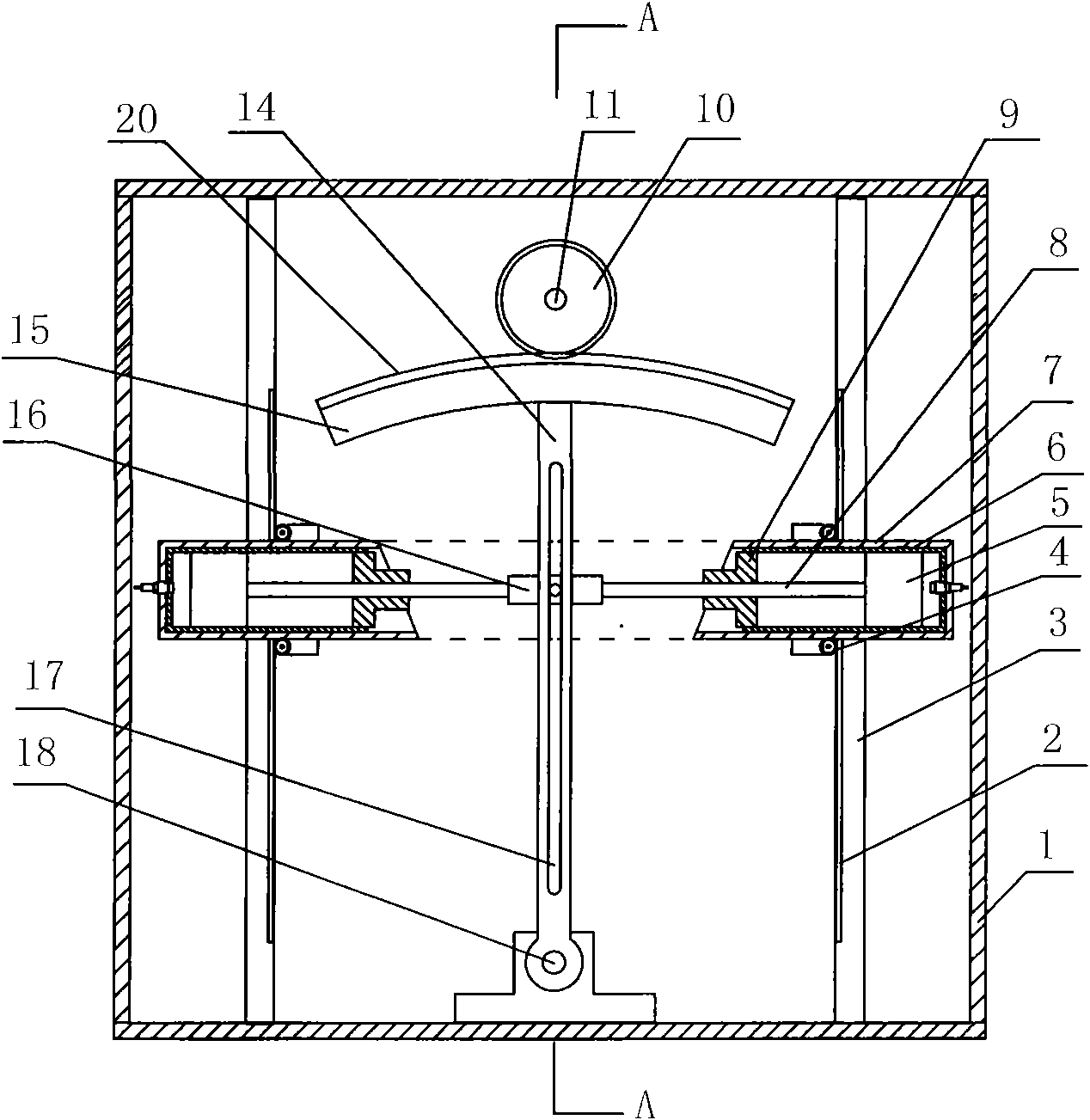

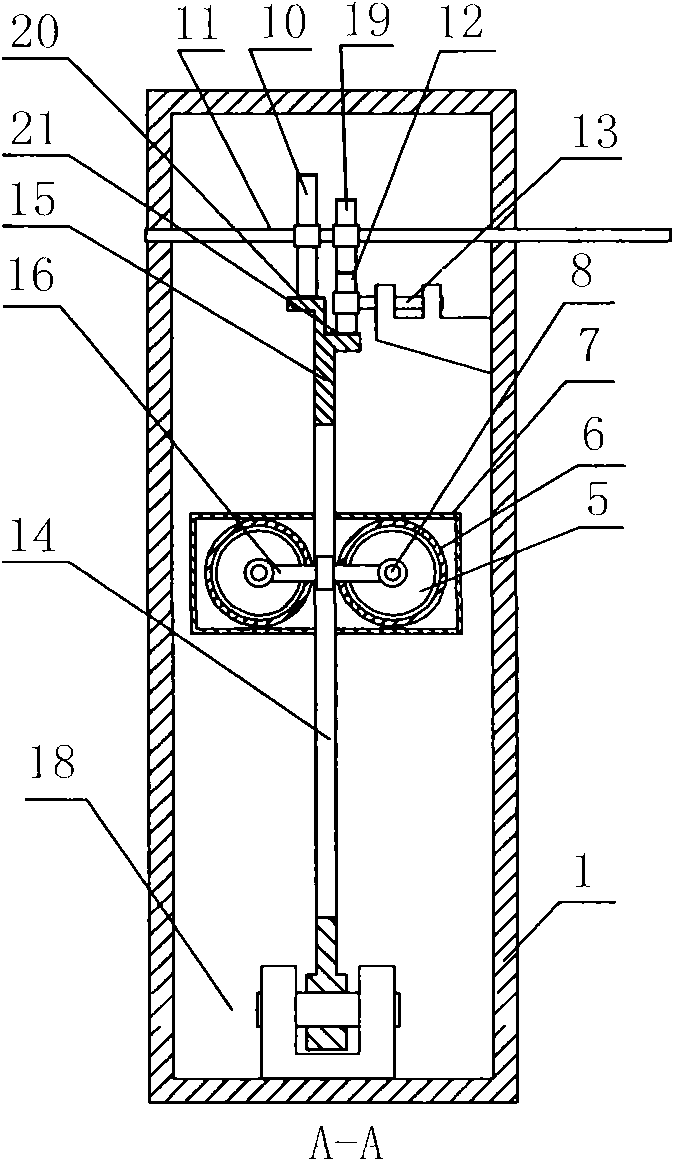

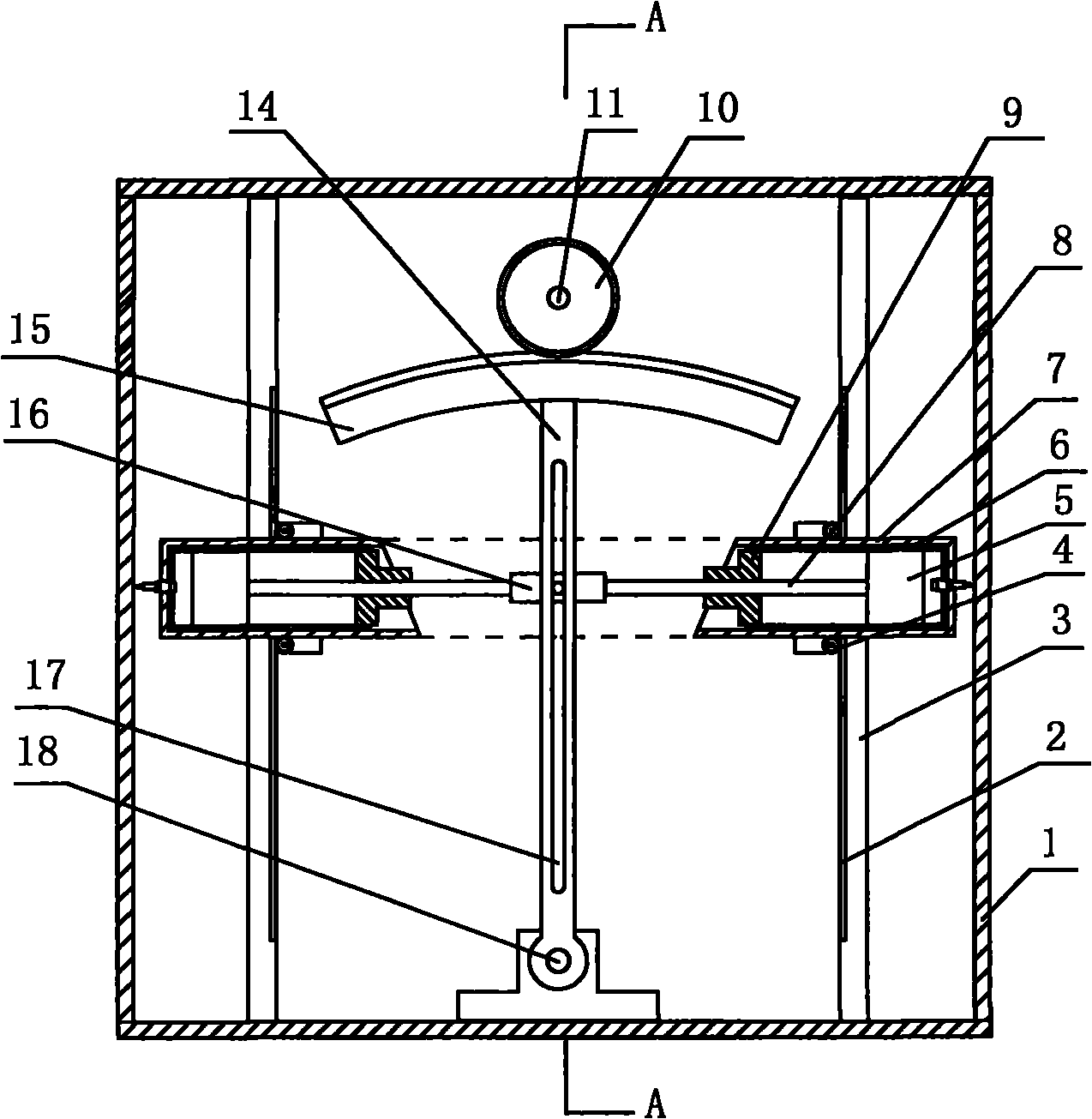

[0020] The attached drawing is just a diagram of the working principle of two pairs of symmetrical cylinder assemblies. Several pairs can be arranged side by side in one cylinder housing. Work on the drive shaft, and finally concentrate on the drive shaft to do work outwards.

[0021] The working principle of the stepless speed change is that the cylinder assembly is relatively arranged on the same axis. There is a swing arm with one end fixed in the middle of the cylinder assembly and an arc-shaped stepped rack at the other end. A chute is vertically arranged in the middle of the swing arm. There is a swing arm slider in the chute, and the oppositely arranged cylinder assemblies are connected together through a connecting rod. The swing arm slider is set in the middle of the connecting rod to drive the swing arm to swing left and right, and then drive the arc-shaped stepped rack to swing left and right to drive A group of one-way gears rotate, and the rotation of the one-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com