Vanadium-nitrogen alloy vacuum furnace

A vanadium-nitrogen alloy and vacuum furnace technology, applied in furnaces, vertical furnaces, furnace types, etc., can solve the problems of non-continuous production, small footprint, long production cycle, etc., achieve semi-automatic production and improve equipment utilization , the effect of shortening the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

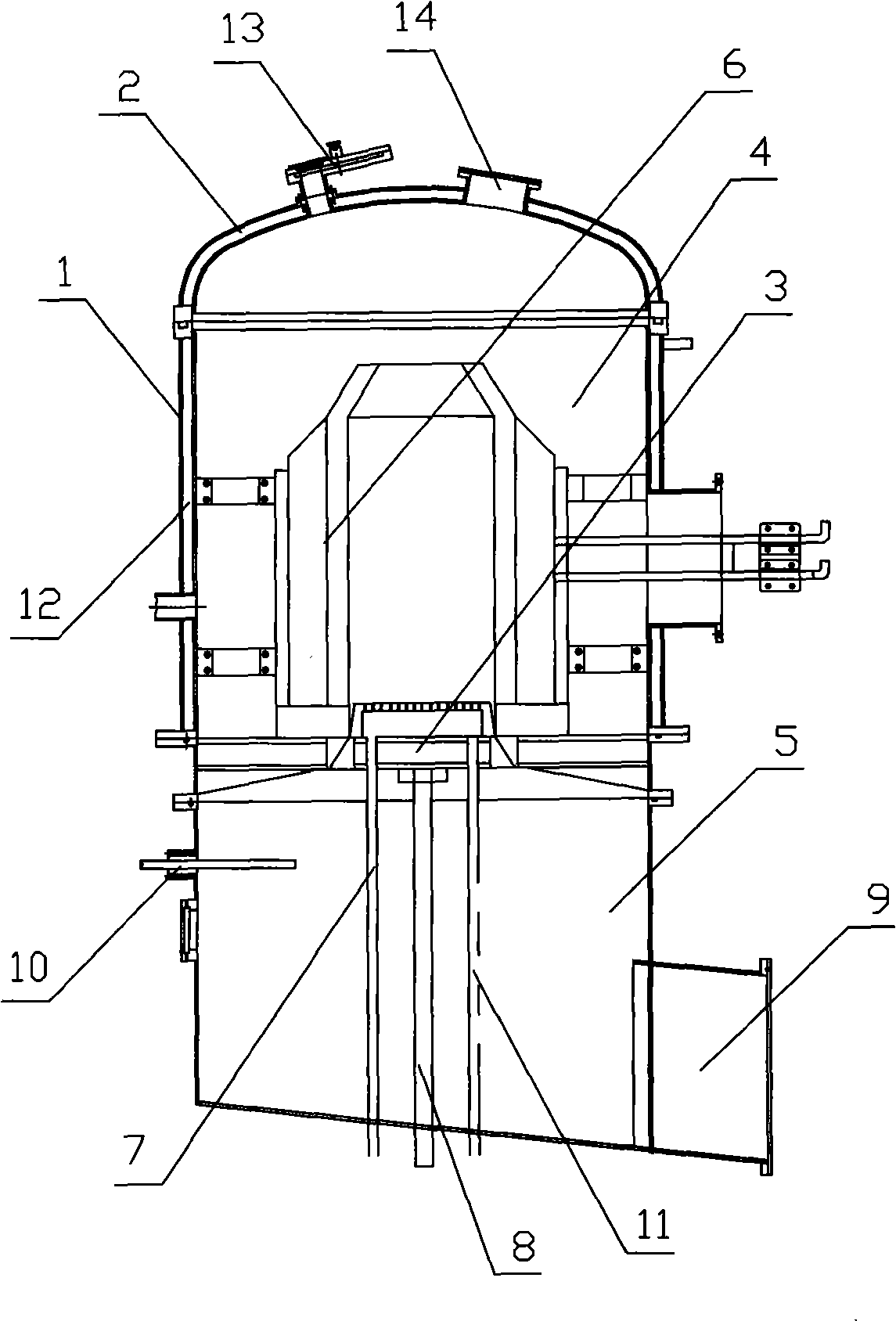

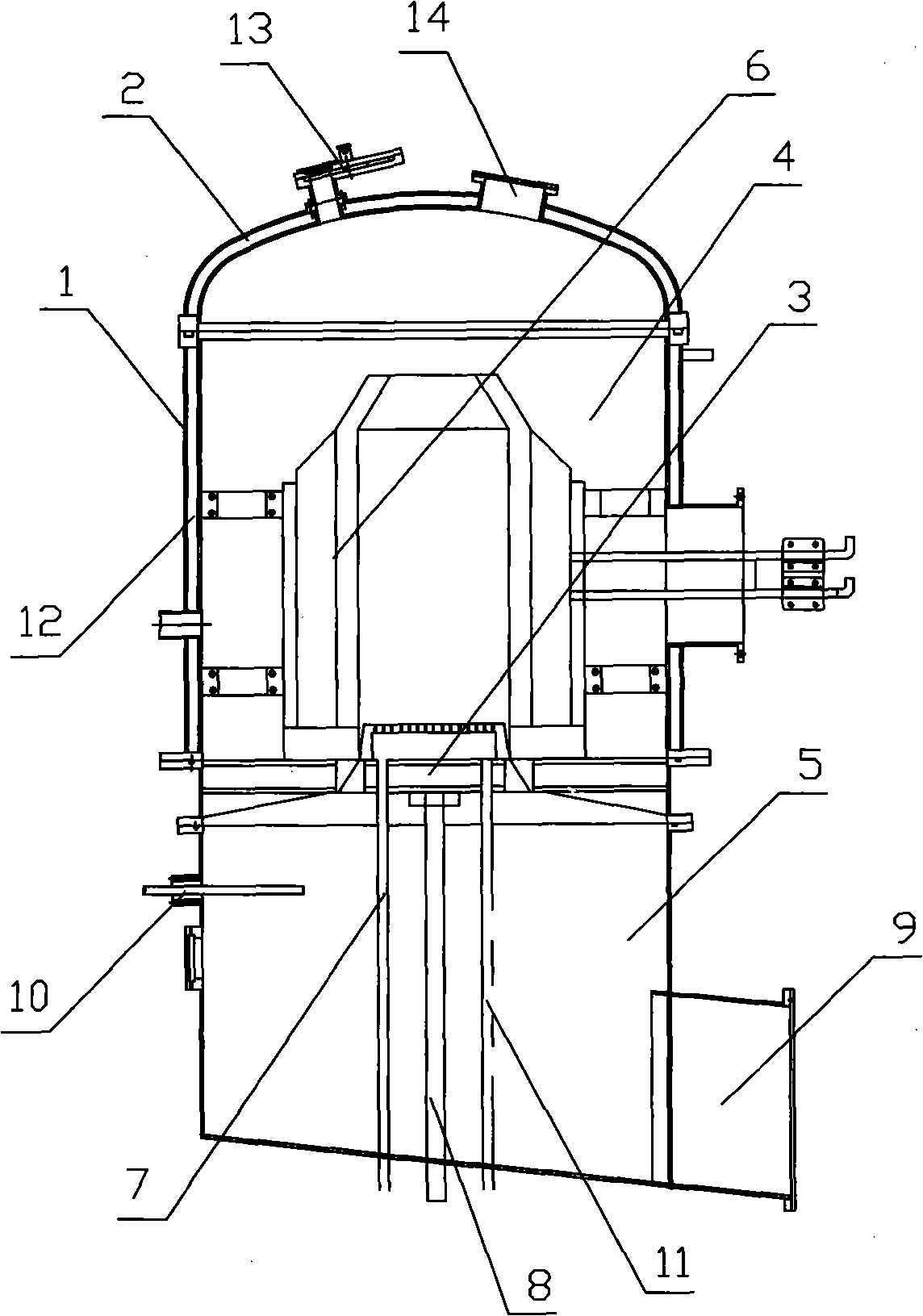

[0010] Such as figure 1 As shown, a vanadium-nitrogen alloy vacuum furnace includes a furnace body 1 and a furnace cover 2 movably connected thereto. The vacuum furnace is divided into a nitriding reaction chamber 4 and an oxygen barrier cooling chamber 5 separated by a tray 3. A heating mechanism 6 is arranged in the nitriding reaction chamber 4, and the nitriding reaction chamber 4 is connected to a nitrogen delivery pipe 7 to enter nitrogen gas. A hydraulic lifting mechanism 8 is arranged below the tray 3. On the side wall of the oxygen-isolated cooling chamber 5 A discharge port 9 and a material shifting rod 10 are provided, and a porous nitrogen diffuser pipe 11 penetrating through the oxygen-isolated cooling chamber 5 is provided at the bottom. The heating mechanism 6 includes an inner crucible and an outer intermediate frequency coil.

[0011] An insulating layer 12 is arranged inside the furnace body 1 .

[0012] Observation windows are provided on the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com