Full-film structure electromagnetic wire thin-film adhesion detection method

A detection method, electromagnetic wire technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., to achieve the effect of simple means, improved detection effect, and reduced detection condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

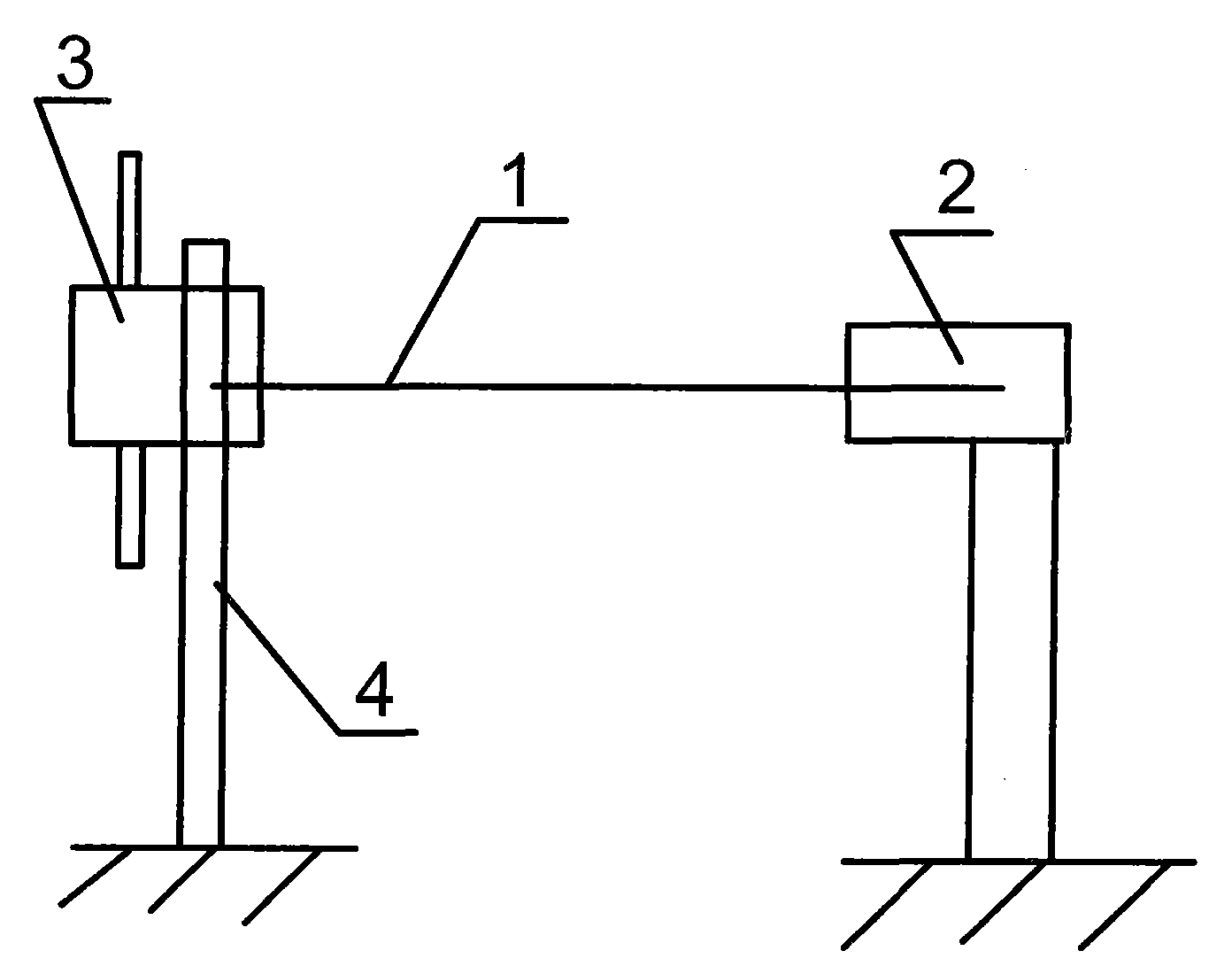

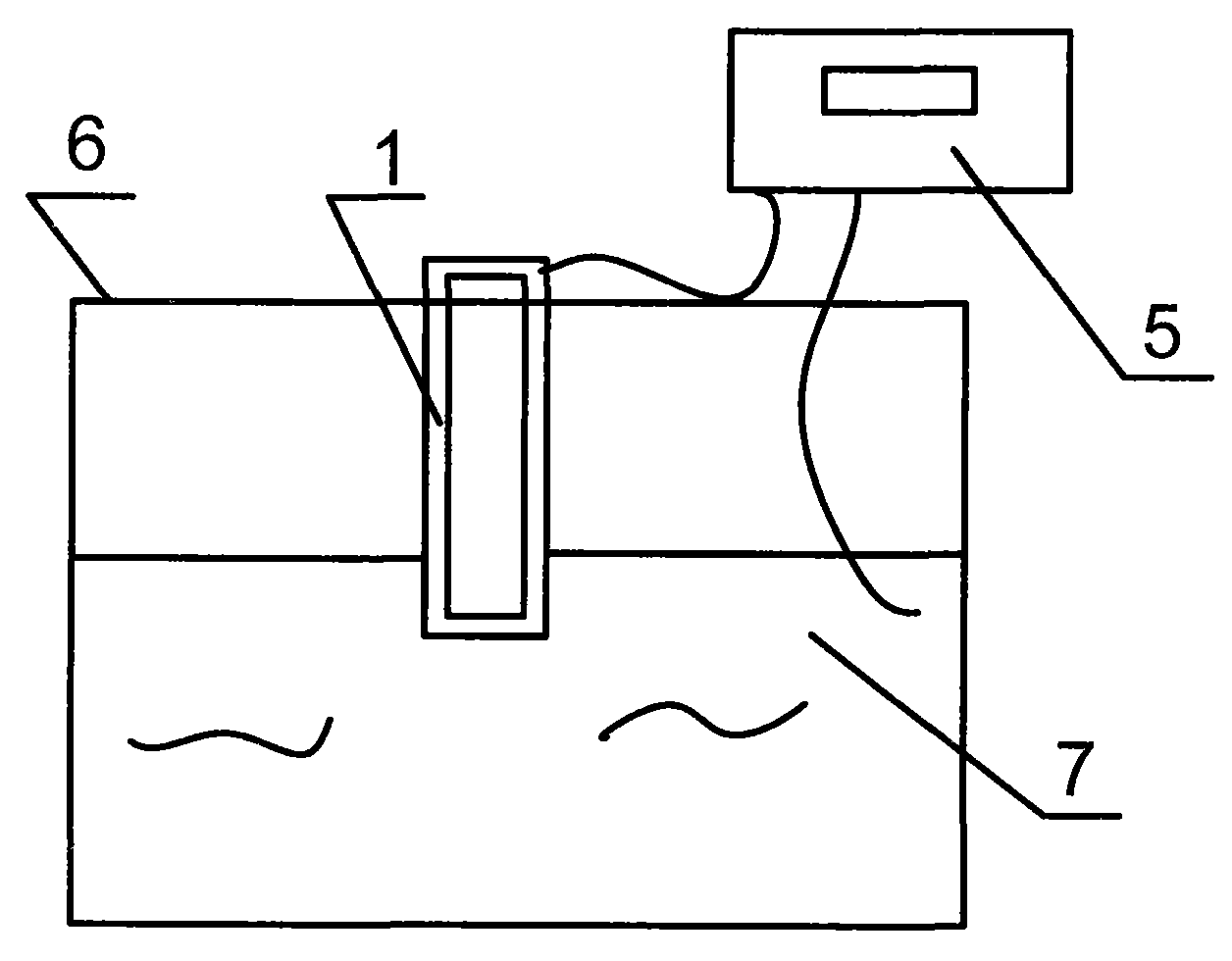

[0012] as attached figure 1 As shown, the present invention is a method for detecting the adhesion of a full-film structure electromagnetic wire film of a motor coil. The method for detecting the adhesion of a full-film structure electromagnetic wire film is divided into two parts; the torsion test and the water immersion test. The detection sequence can be reversed; the torsion test is to respectively clamp a section of finished electromagnetic wire by a clamping device, and judge the linear torsion performance of the film adhesion of the full-film structure electromagnetic wire by the relative torsion of the clamping device; the described water immersion The test is to immerse the twisted part of the finished magnet wire into a container filled with water, and use a 1000V class insulation resistance tester to touch the copper conductor of the finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com