Cantilever beam type accelerometer based on photonic crystal microcavity

A photonic crystal microcavity and cantilever beam technology, which is applied in the direction of measurement of acceleration, velocity/acceleration/shock measurement, optical waveguide coupling, etc., can solve the problems of difficult improvement of performance parameters such as resolution and sensitivity, and expand the scope of application , light weight and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

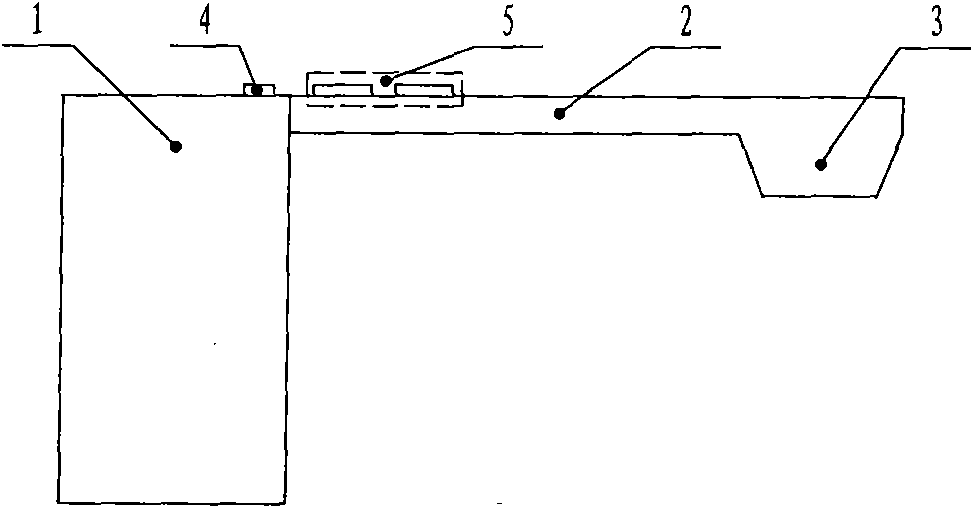

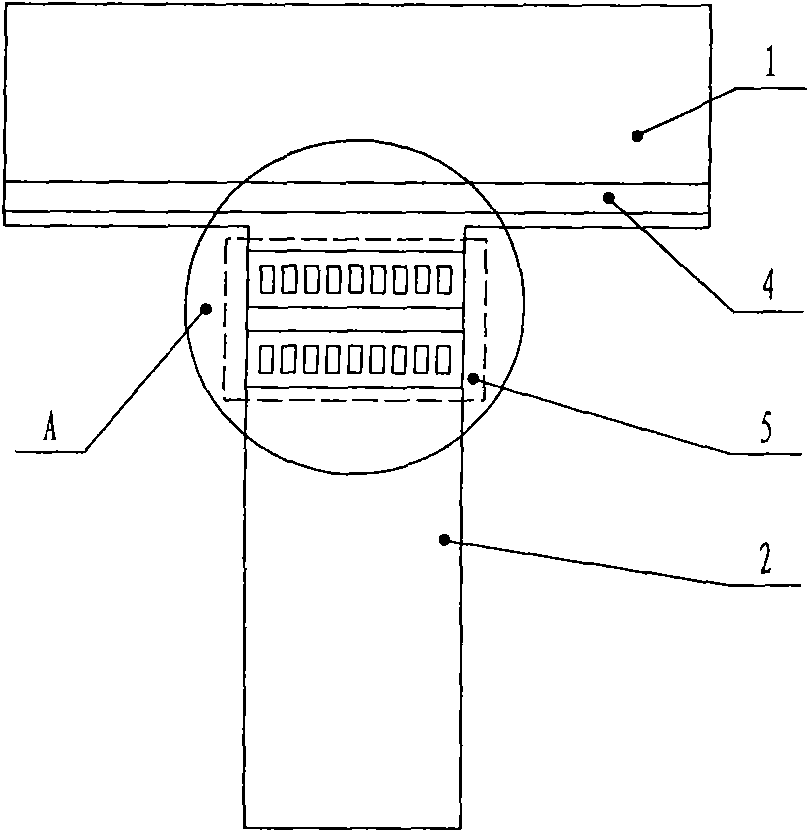

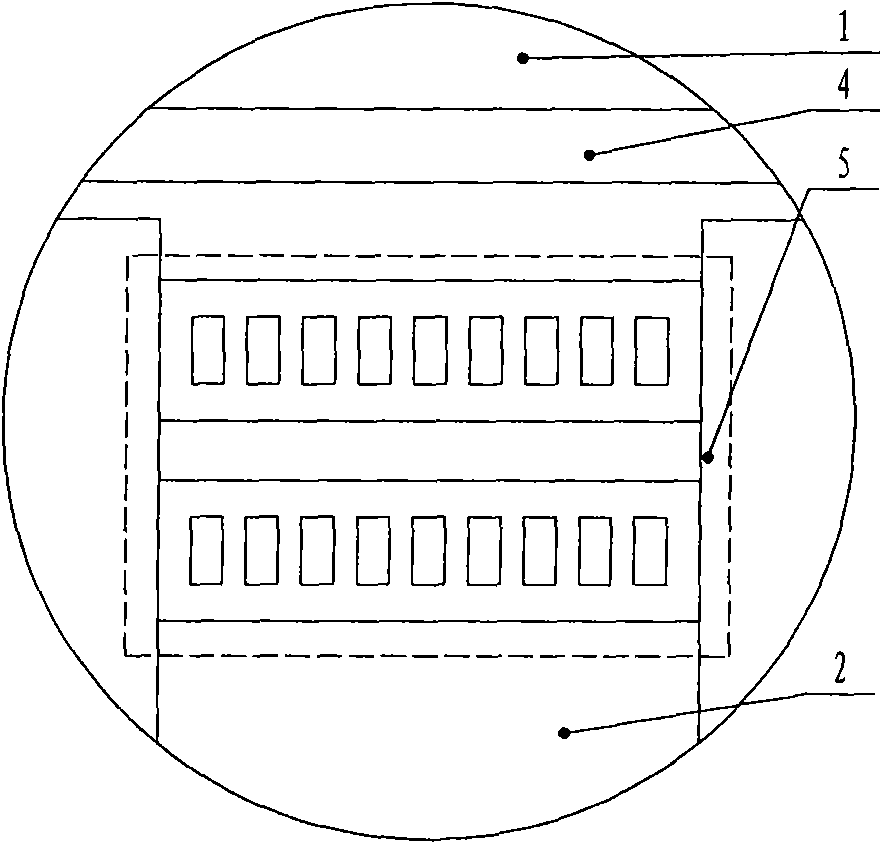

[0017] like Figure 1-3 As shown, the cantilever beam accelerometer based on the photonic crystal microcavity includes the base 1 processed on the semiconductor substrate by the micro-electromechanical device processing technology (MEMS processing technology), and the cantilever beam fixed to the base 1 at one end 2. The mass block 3 fixed to the free end of the cantilever beam 2, the base 1 is provided with an optical waveguide 4 perpendicular to the cantilever beam 2, and the end of the cantilever beam 2 fixed to the base 1 is provided with a "zipper cavity (Zippercarity) 5. The two brackets of the "zipper cavity" 5 are parallel to the optical waveguide 4 on the base 1, and the "zipper cavity" 5 and the optical waveguide 4 form a microcavity-optical waveguide coupling structure.

[0018] During specific implementation, the material of the "zipper hole" 5 is silicon nitride Si 3 N 4 , the material of the optical waveguide is silicon dioxide SiO 2 In the cantilever beam str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com