Grinding center and method for the simultaneous grinding of multiple crankshaft bearings

A crankshaft and main bearing technology, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., can solve the problem of large space control device consumption and other problems, and achieve the effect of reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

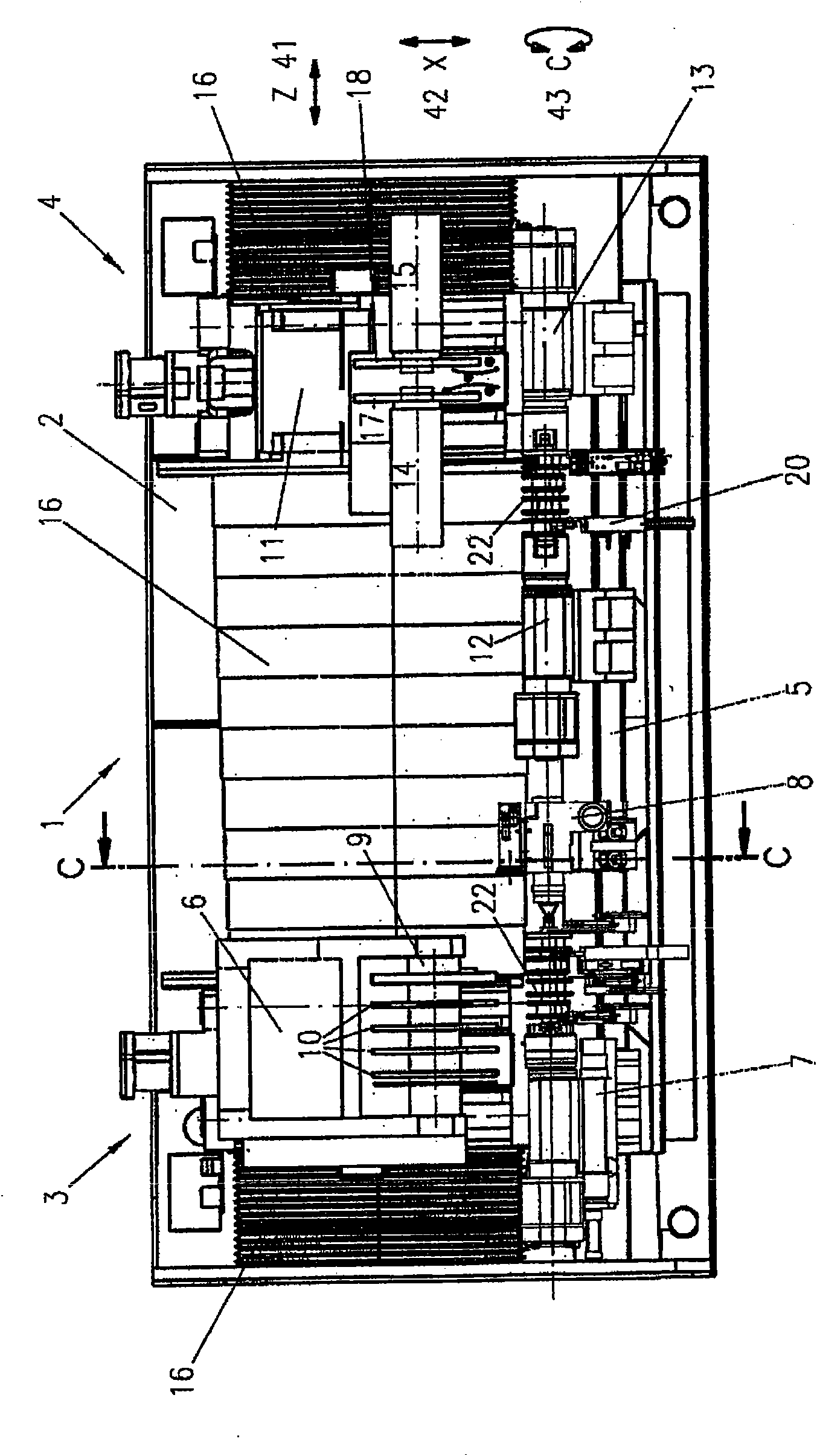

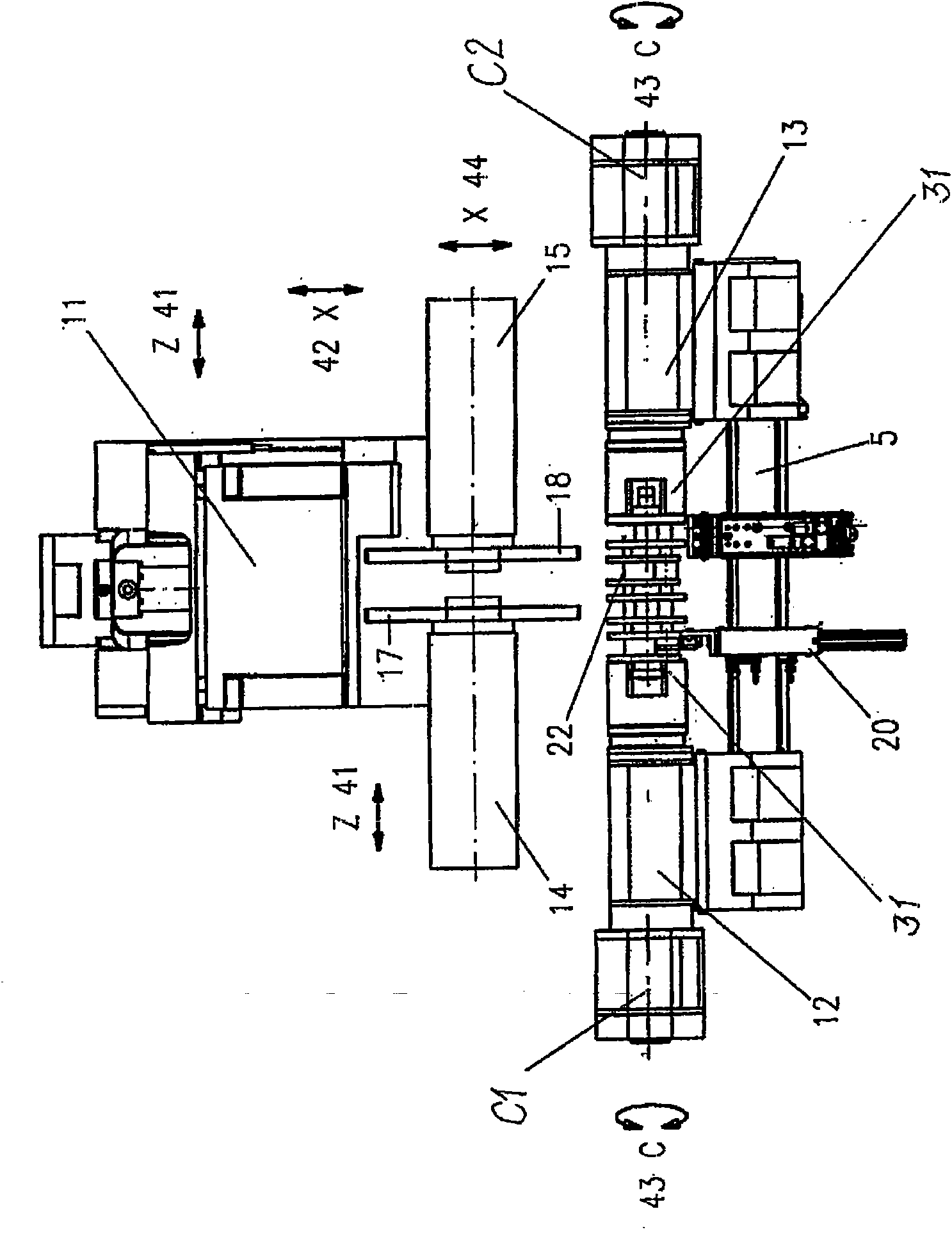

[0032] exist figure 1 A plan view of a grinding center designed as a grinding unit 1 is shown in . The grinding unit has a common machine tool 2 on which two stations 3 , 4 are arranged for machining the crankshaft 22 by grinding. The stations 3 , 4 have a common grinding table 5 on which a holding device and a drive device for the crankshaft 22 are located. The grinding unit usually also has a hood and a loading and unloading device for feeding in and removing the crankshaft 22 and transporting it from the first station 3 to the second station 4 . However, the loading and unloading device is figure 1Not shown, nor are the CNC control with input keys and the hydraulic and / or pneumatic supply.

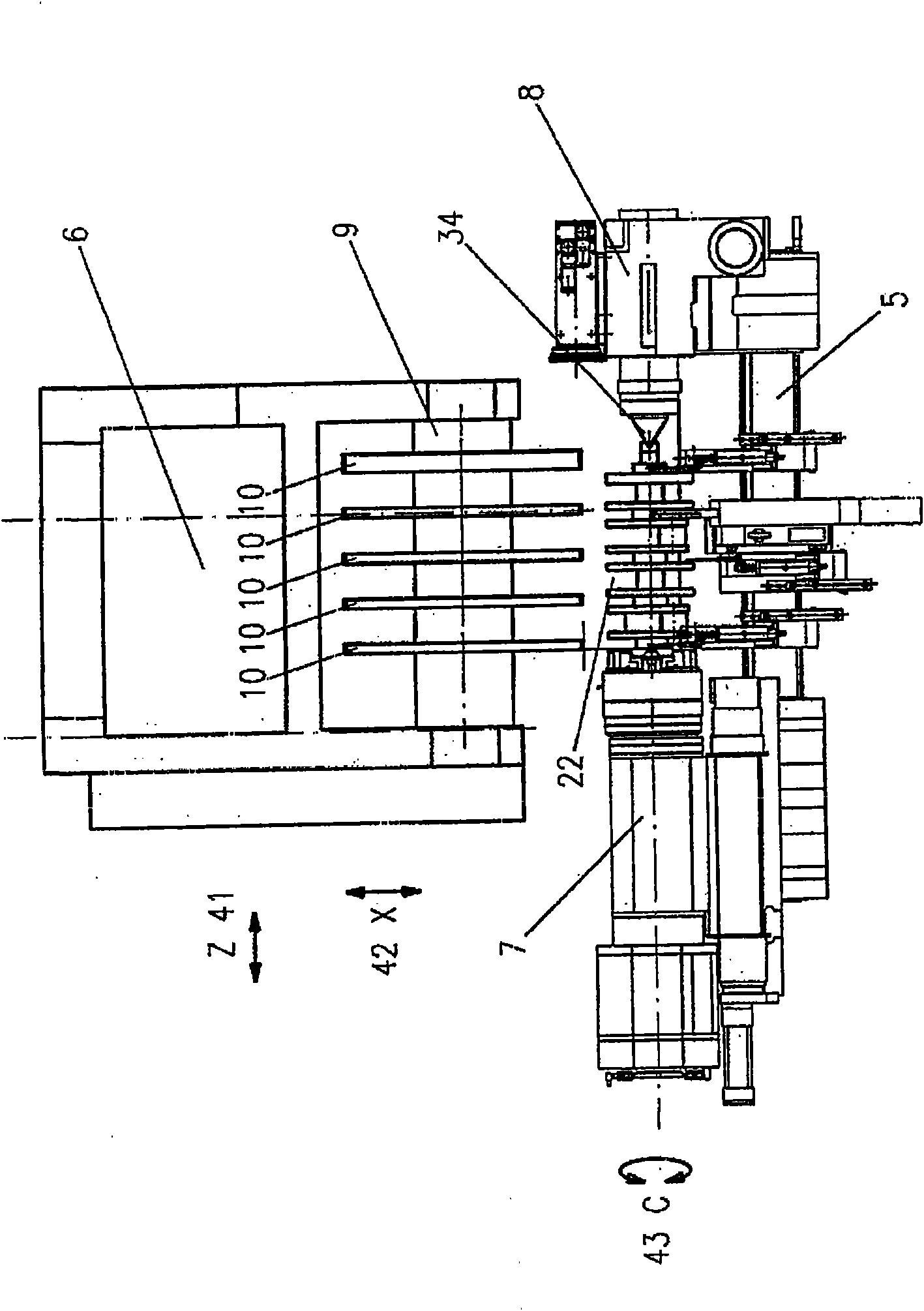

[0033] exist figure 2 The first station 3 of the grinding unit 1 shown separately in FIG. 2 is used for grinding the main bearing 23 of the crankshaft 22 . For the sake of illustration, the most important functional parts of the first station 3 are shown in the auxiliary figure "m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com