Sound producing system

A technology of sound wave and electroacoustic converter, which is applied in the field of acoustics and can solve problems such as damage to electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

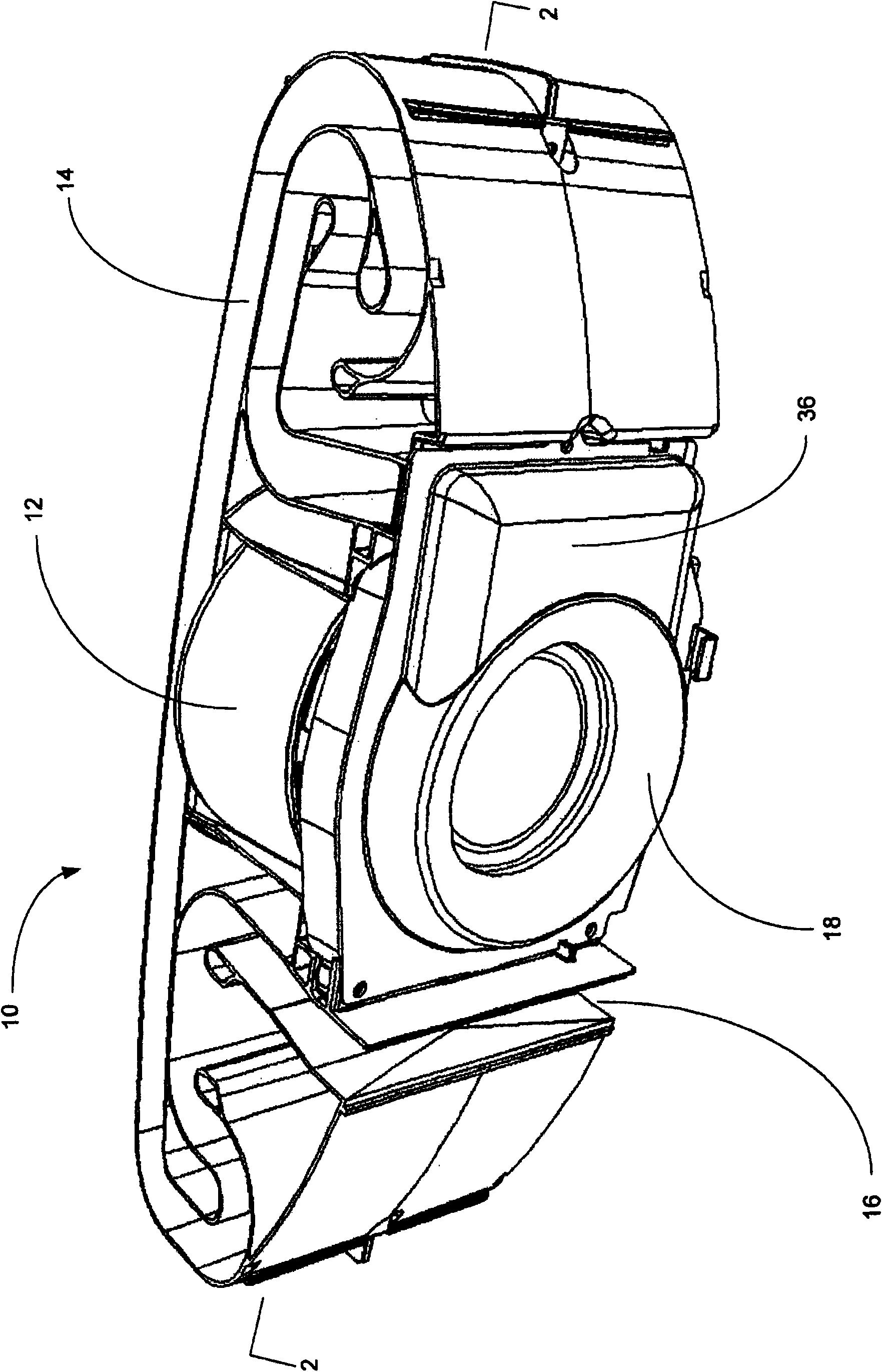

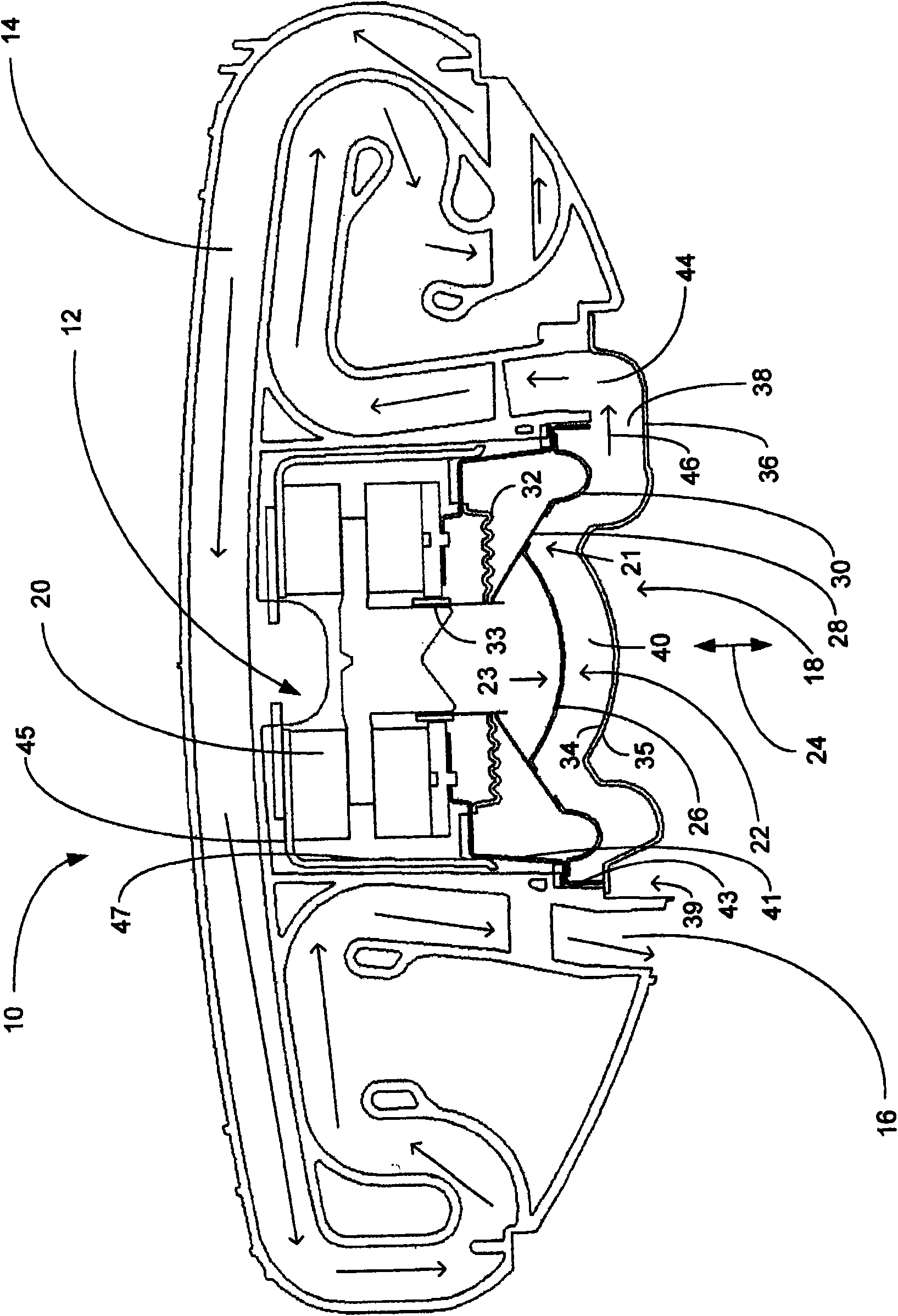

[0014] refer to figure 1 , shows a sound generation system 10 for playing audio out loud. The housing of system 10 has been removed for ease of viewing. System 10 includes an electro-acoustic transducer 12, in this example a woofer. The system has a waveguide 14 which includes a waveguide outlet 16 . The sound waves generated by the system are sent by the waveguide 14 and the waveguide outlet 16 to the listening environment outside the system. A converter housing 18 is positioned adjacent to the converter 12 and secured to the frame of the system 10 . The enclosure is a solid airtight structure, preferably made of a magnetically permeable material such as 1.5 mm thick cold rolled steel (CRS). An example of a CRS with a permeability of about 2.5k N / A 2 Grade 1010 (low carbon steel). Other materials from which the cover 16 can be made include 2 High magnetic permeability nickel-iron alloy with a magnetic permeability of about 5k N / A 2 Permalloy, with a magnetic permeabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com