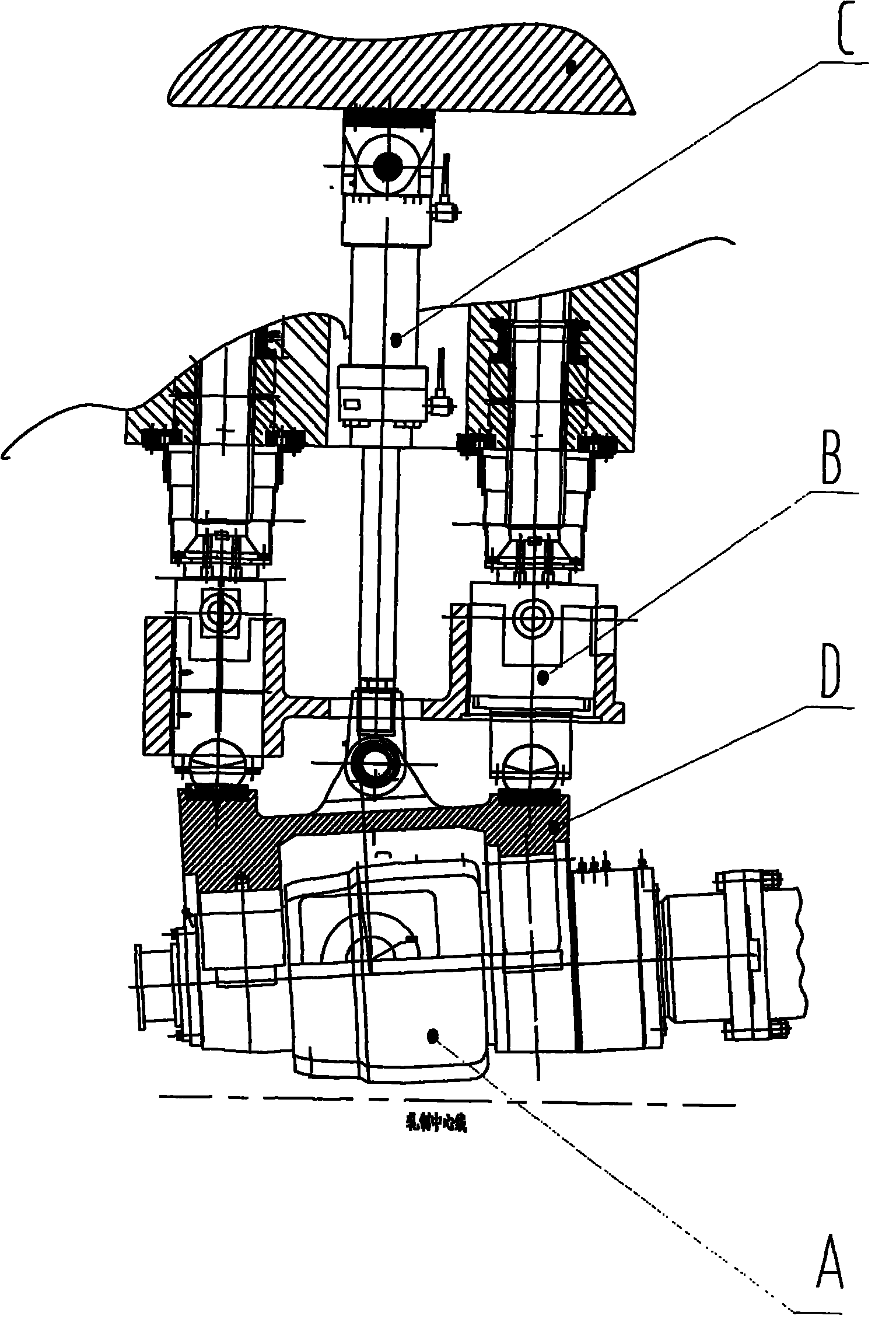

Hydraulic control system for king roller quick-opening device of pipe mill

A hydraulic control system, the technology of the main roll, applied in the direction of rolling force/roll gap control, etc., can solve the problems of not being able to maintain the original position and the fast opening speed is slow, and achieve the effect of improving the fast opening speed and the pressure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

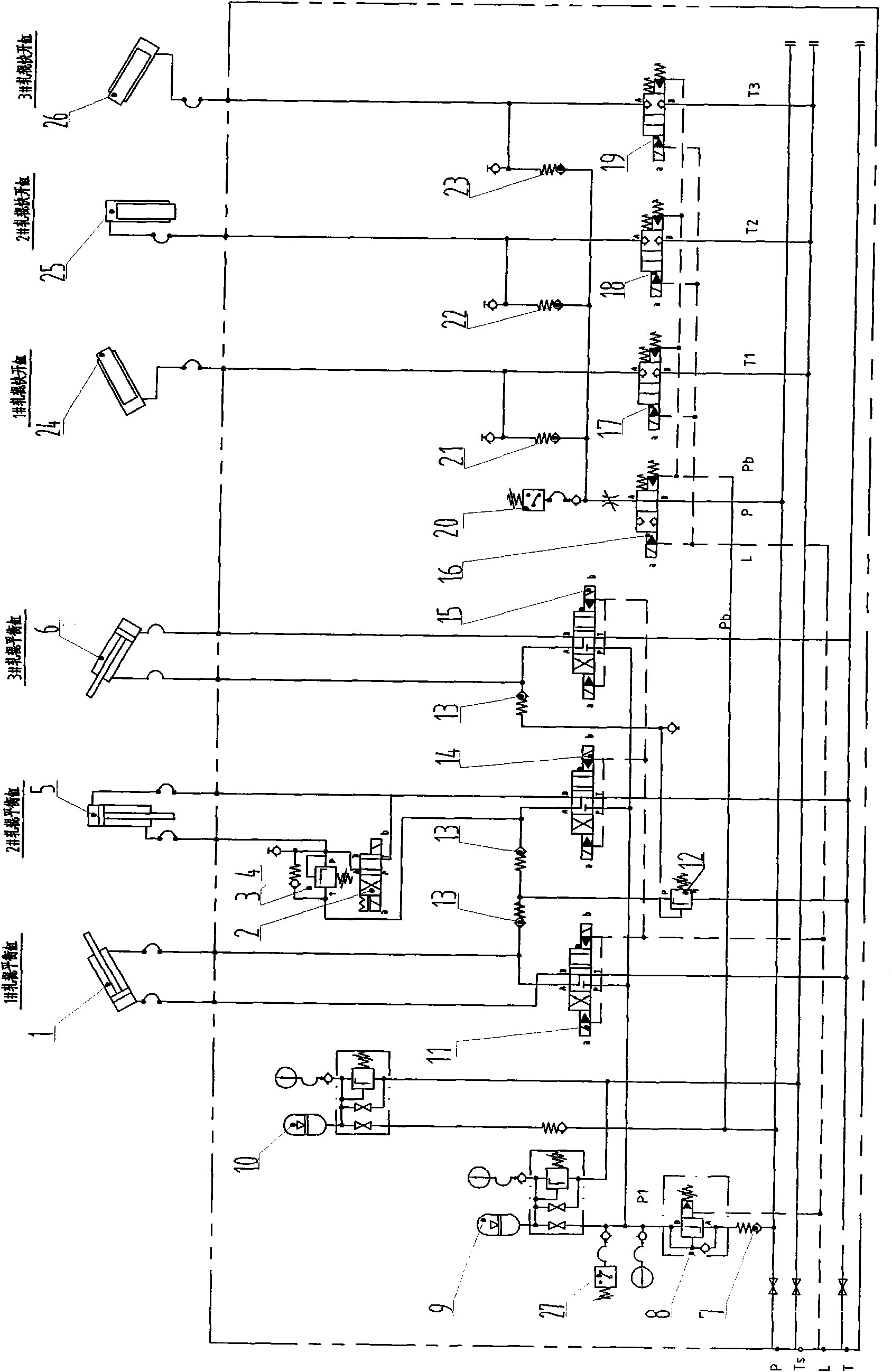

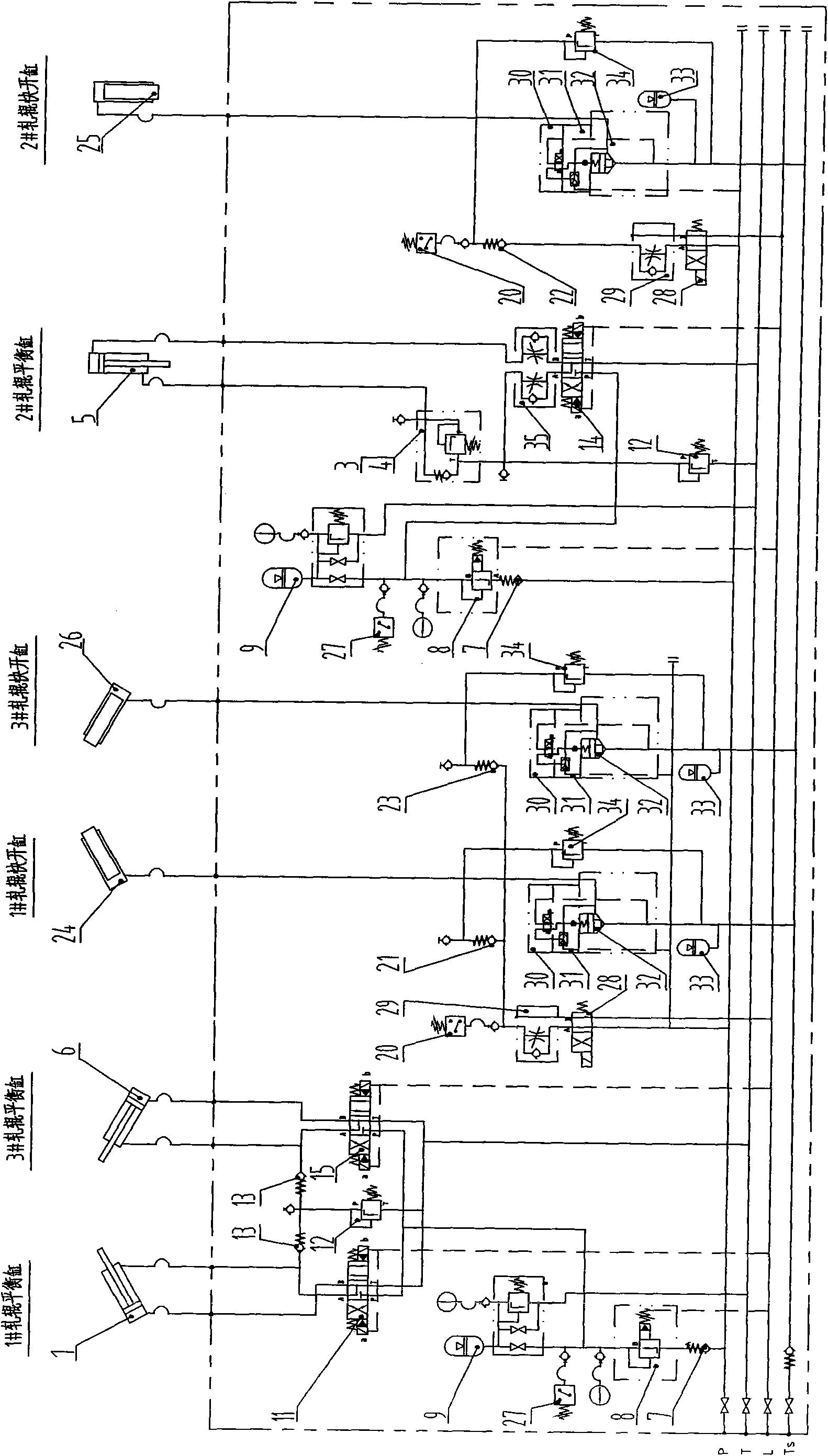

[0018] like image 3 As shown in the figure, a hydraulic control system of the quick-opening device for the main roll of a pipe rolling mill is composed of a pressure reducing valve 8, a one-way valve 7 and an accumulator 9 to form a pressure reducing and stabilizing circuit of the balance cylinder balance circuit, and the 1# roll balance cylinder 1 and 3# roll balance cylinders 6 are controlled by Y-type functional directional valves 11 and 15, and 2# roll balance cylinder 5 is composed of Y-type functional directional valve 14, one-way throttle valve 35, overflow valve 3, and one-way valve 4 The low-pressure balance block control, the one-way valve 13 and the safety valve 12 form a high-pressure protection circuit, and the one-way valves 21, 22, 23, the directional valve 28, and the one-way throttle valve 29 respectively form the 1# roll quick opening cylinder 24, 2 The oil inlet circuits of #roll quick opening cylinder 25 and 3# roll quick opening cylinder 26, the cartridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com