Method for adjusting roll axial direction of multi-diagonal roll straightener

A technology of axial adjustment and straightening machine, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of inability to fix, overturn, and heavy upper roll device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

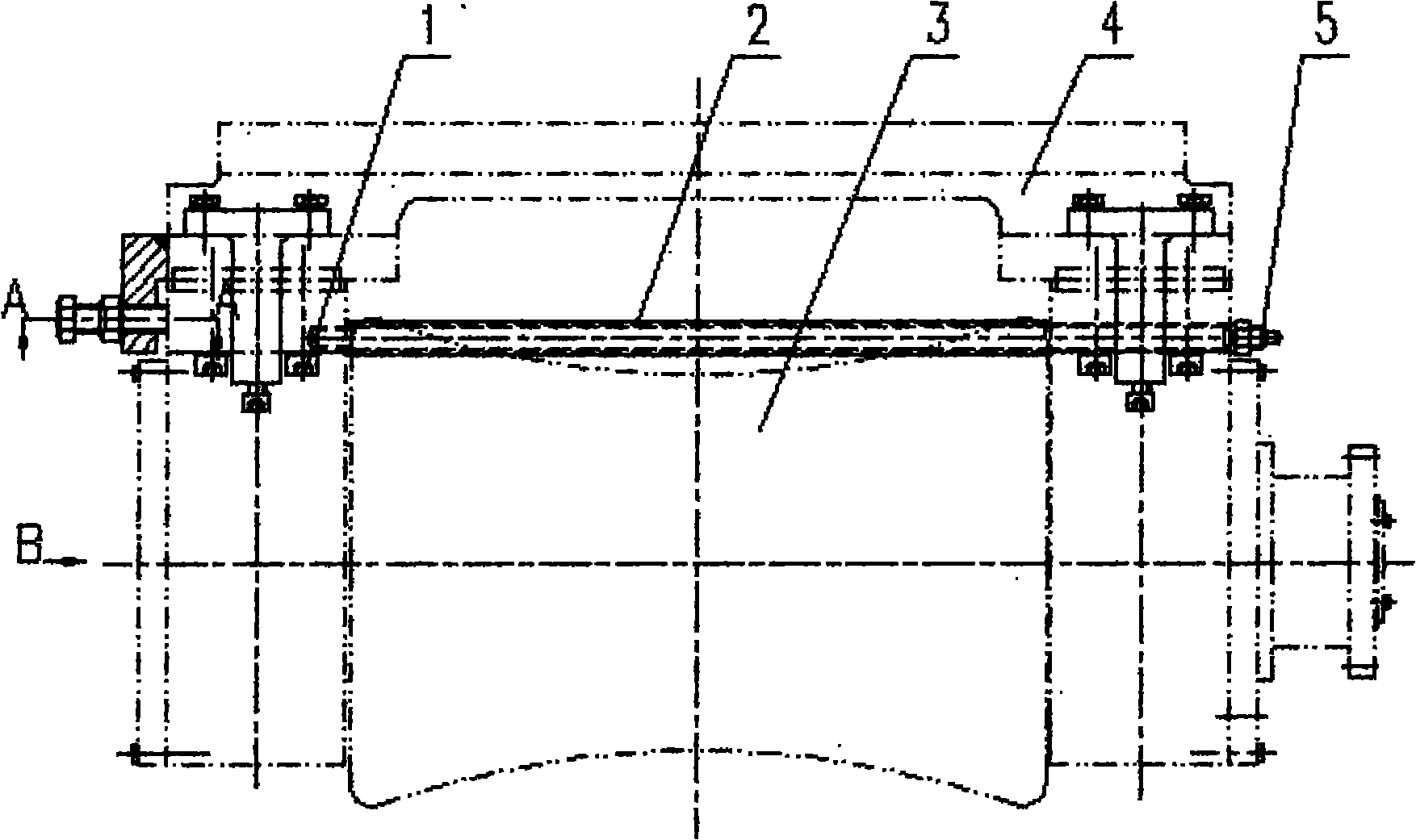

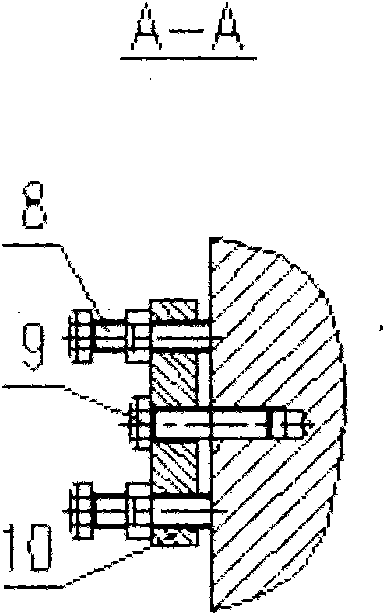

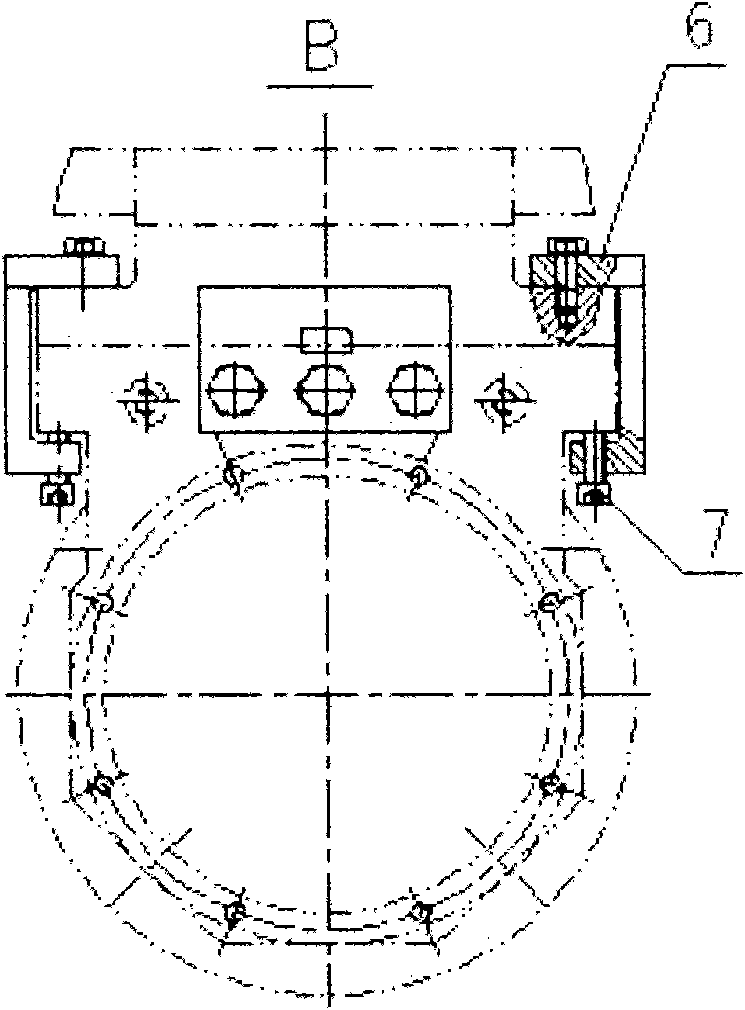

[0016] Such as figure 1 , 2 , shown in 3: a method for axial adjustment of the upper roller of a multi-skewed roller leveler, the adjustment device of the upper straightening roller of the leveler is set to an axial adjustment form and a lateral fixed and vertical adjustment form, and the axial adjustment form The end surface of the axial adjustment bolt bracket is provided with an axial adjustment bolt for adjusting the axial direction of the upper straightening roller device. The side of the turntable of the straight roller device; the lateral fixation and vertical adjustment form, the upper and lower ends of the C-shaped frame are provided with vertical adjustment bolts to withstand the bearing seat; the C-shaped frame and the turntable of the upper straightening roller device are fixed Fixed, stuck on the outer edge of the bearing seat and the turntable. The axial adjustment device of the upper roll of the straightening machine consists of a bolt (1), a distance tube (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com