Device for grinding two end surfaces of arc spring

A two-end surface and arc-shaped technology, which is applied in the direction of grinding machines, grinding/polishing equipment, and machine tools suitable for grinding workpiece planes, etc., to achieve high efficiency, reasonable process design, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further specifically described below through examples.

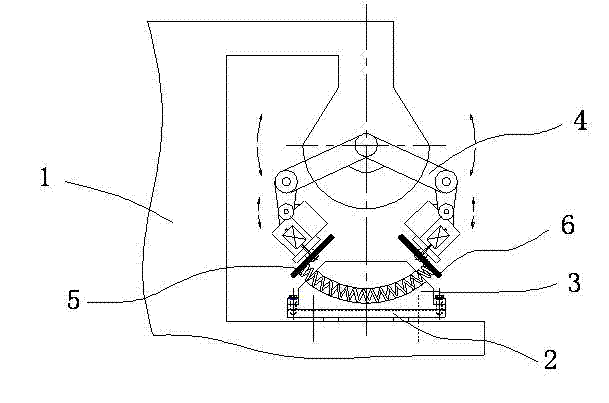

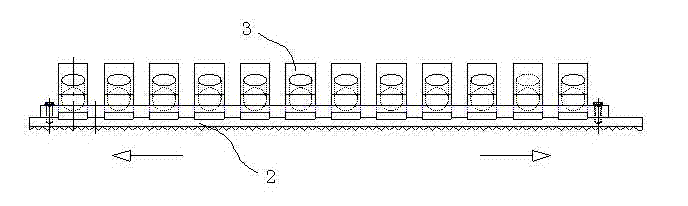

[0018] In this embodiment, a device for smoothing both ends of an arc-shaped spring is provided with a machine base 1, and a single beam is arranged above the machine base 1, see figure 1 , the bottom of the single beam is a strip-shaped workbench, which is provided with a rack grinding plate 2, and the stroke of the workbench can be adjusted, such as image 3 As shown, 12 pairs of clip spring devices 3 are assembled in parallel on the rack grinding plate 2, and the rack and pinion transmission mechanism is arranged under the rack grinding plate 2 and is connected with the driving device.

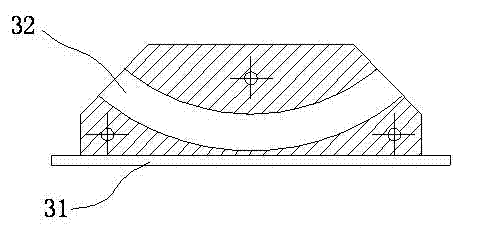

[0019] The clamp spring device 3 is provided with a clamp spring base 31, an arc-shaped positioning groove 32 and a one-way pressing device, and the clamp spring base 31 is provided with a mounting hole through which the clamp spring device 3 is fixed on the workbench. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com