Hydroxyapatite nanotube and preparation and application thereof in bone repair

A technology of hydroxyapatite and nanotubes, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effect of simple process, low cost, and superior biomedical application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

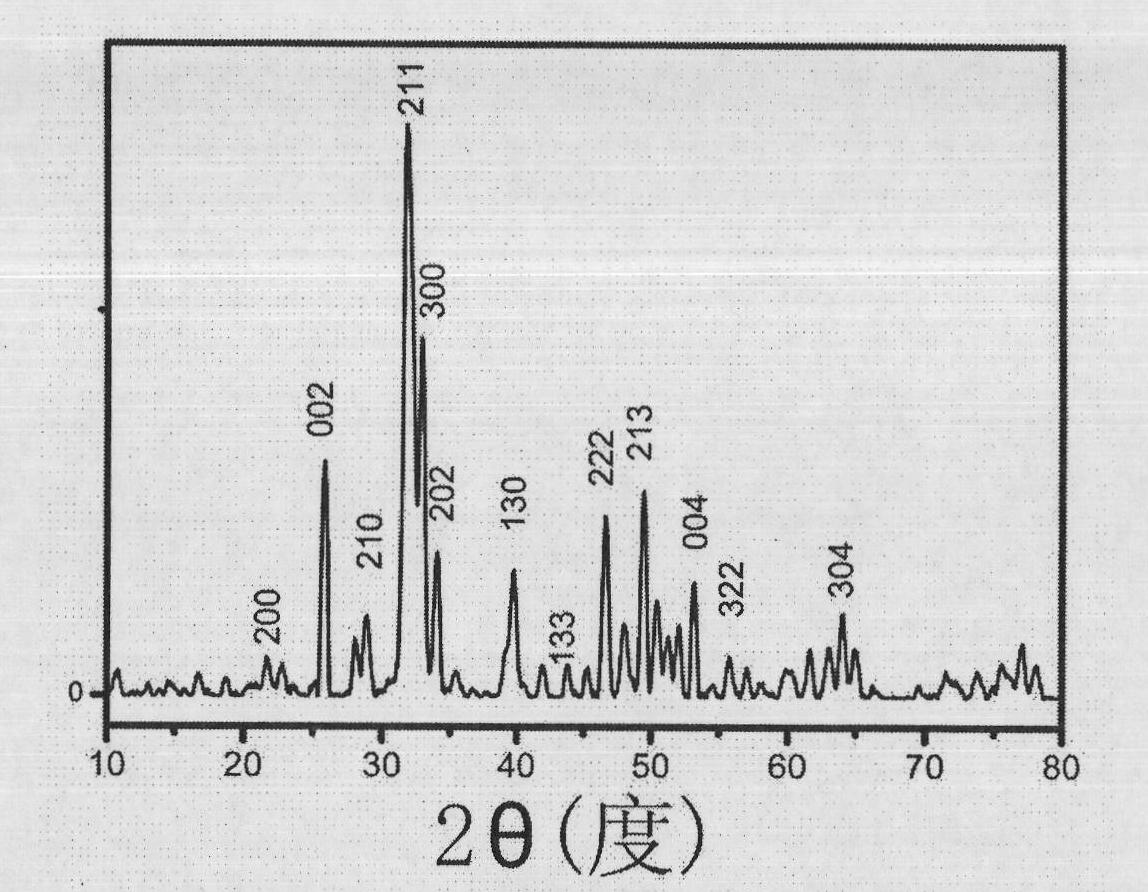

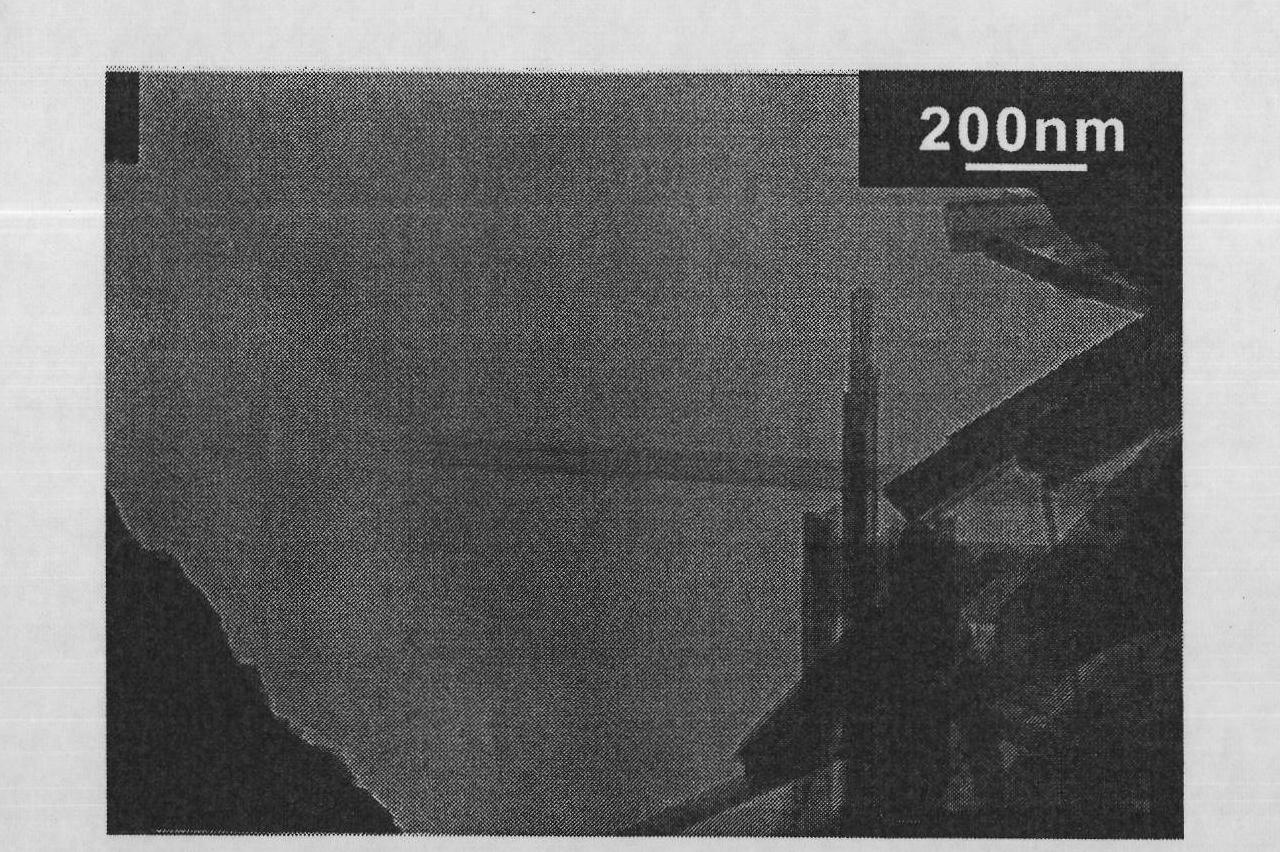

[0037] Dissolve 0.004mol of ammonium dihydrogen phosphate and 0.006mol of calcium chloride in 40ml of water, then add 10ml of ethanol solution containing 0.006mol of octadecylamine, stir for 60 minutes, and transfer the above mixed solution to a stainless steel autoclave , treated at 120° C. for 72 hours, cooled to room temperature after the reaction was complete, and finally centrifuged to obtain a precipitate, which was washed with deionized water and dried to obtain hydroxyapatite nanotubes. The product was identified as hydroxyapatite by X-ray powder diffraction (see figure 1 ), TEM electron microscope inspection product morphology (see figure 2 ).

Embodiment 2

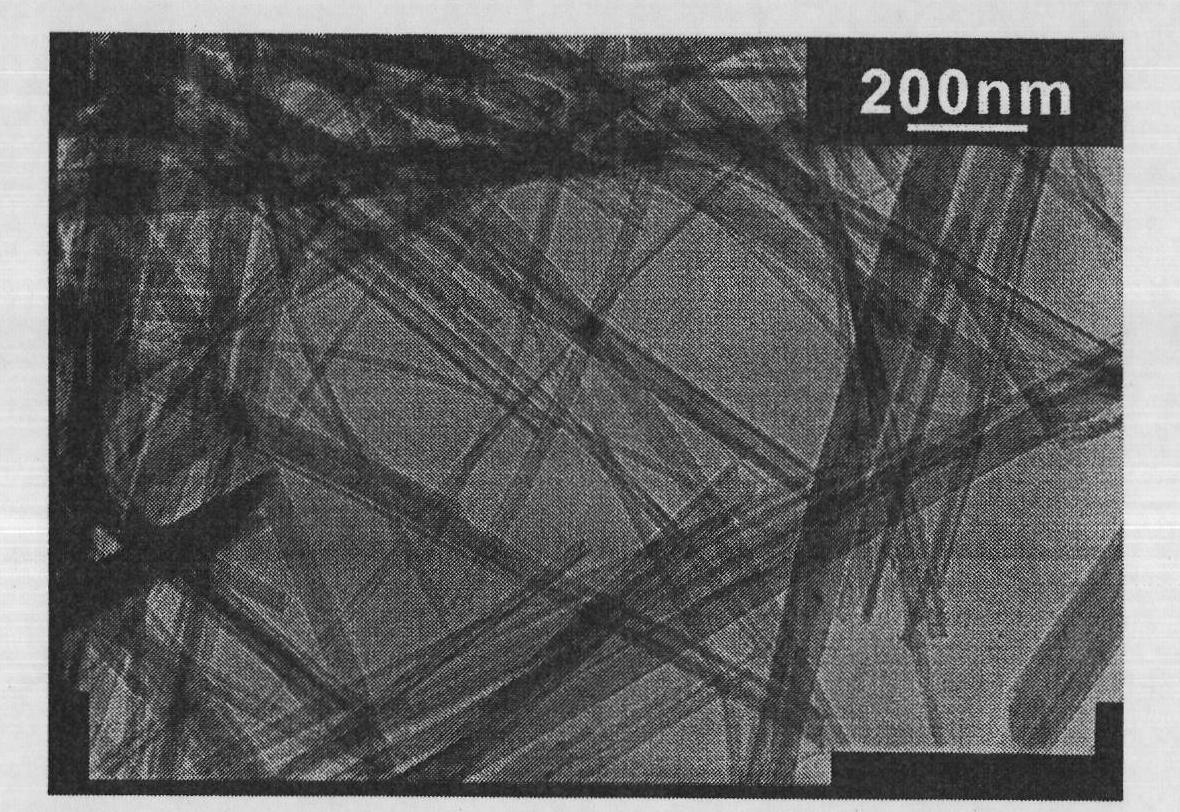

[0039] Dissolve 0.006 mol of sodium dihydrogen phosphate and 0.009 mol of calcium chloride in 40 ml of water, then add 10 ml of decylamine ethanol solution containing 0.01 mol, stir for 60 minutes, transfer the above mixed solution to a stainless steel autoclave, Treat at 110° C. for 48 hours, cool to room temperature after the reaction is complete, and finally centrifuge to obtain a precipitate, which is washed with deionized water and dried to obtain hydroxyapatite nanotubes. The product is identified as hydroxyapatite through X-ray powder diffraction, and the product morphology is detected by TEM electron microscopy (see image 3 ).

Embodiment 3

[0041] Dissolve 0.01 mol of potassium dihydrogen phosphate and 0.015 mol of calcium nitrate in 40 ml of water, then add 10 ml of 0.01 mol of hexadecylamine ethanol solution, stir for 60 minutes, transfer the above mixed solution to a stainless steel autoclave, Treat at 150° C. for 24 hours, cool to room temperature after the reaction is complete, and finally centrifuge to obtain a precipitate, which is washed with deionized water and dried to obtain hydroxyapatite nanotubes. The product is identified as hydroxyapatite through X-ray powder diffraction, and the product morphology is detected by TEM electron microscopy (see Figure 4 ).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap