Reflux liquid inlet device for high-load anaerobic reactor

An anaerobic reactor and liquid inlet device technology, applied in the fields of environmental protection engineering and chemical engineering, can solve the problems of slow outlet flow rate, complicated pipelines, adverse reactions of microorganisms, etc., to improve the outlet pressure and flow rate, and increase the pH buffer capacity. , beneficial to the effect of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

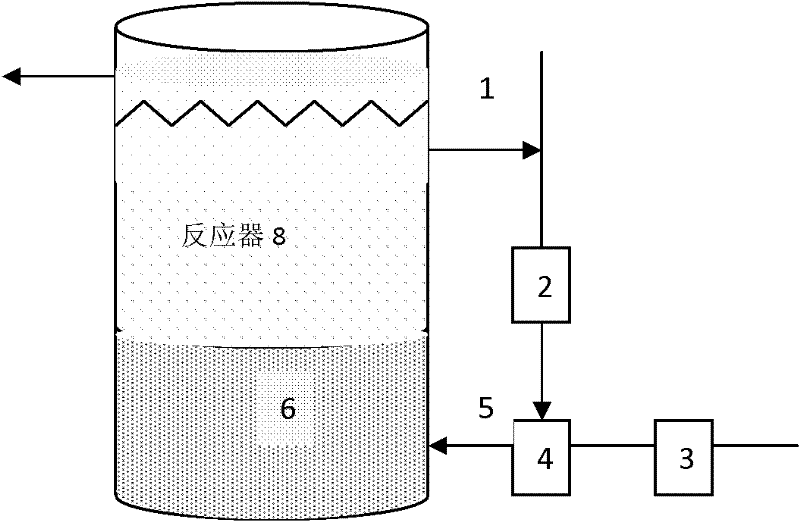

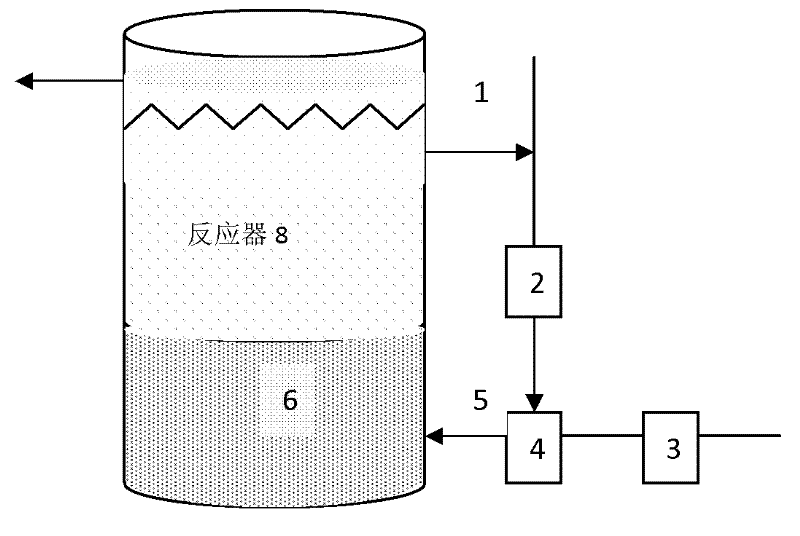

[0019] refer to figure 1 , figure 2 As shown, the upper end of the anaerobic reactor 8 is connected with an outlet pipeline 1, and the outlet pipeline 1 is connected to the pipeline circulation pump 2, and the circulation pump 2 is connected to the mixing device 4 through the pipeline, and the mixing device 4 enters the anaerobic reactor through the liquid inlet pipe 5. At the bottom 6 of the oxygen reactor 8, the anaerobic feed pump 3 is connected to the mixing device 4 through a pipeline.

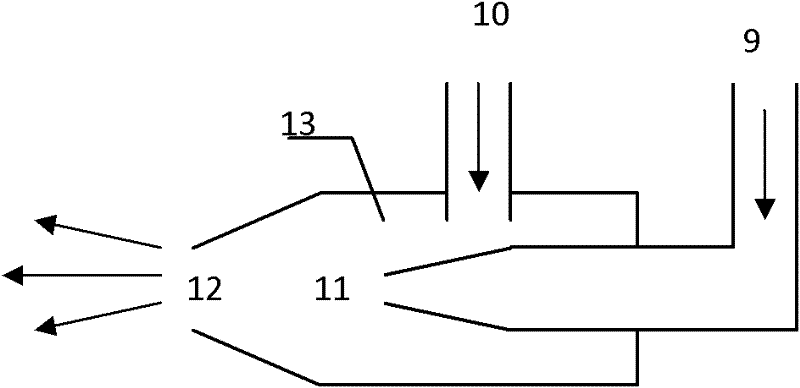

[0020] The mixing device 4 includes a mixing chamber 13, the top center of the mixing chamber 13 has a waste water inlet 10 to be treated, and the right middle part has a circulating water inlet 9, and the liquid inlet 9 is connected to the nozzle 11 located in the mixing chamber 13, and the outside of the mixing chamber 13 An external spout 12 is provided.

[0021] In order to ensure that the wastewater can be evenly distributed when it enters the reactor, and to overcome the shortcom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com