Multispectral uniform surface light source

A multi-spectral, surface light source technology, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of unable to realize spectral responsivity detection, complicated processing of curved reflector, affecting the accuracy of camera measurement, etc., to achieve multi-spectral Color mixing, light weight, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

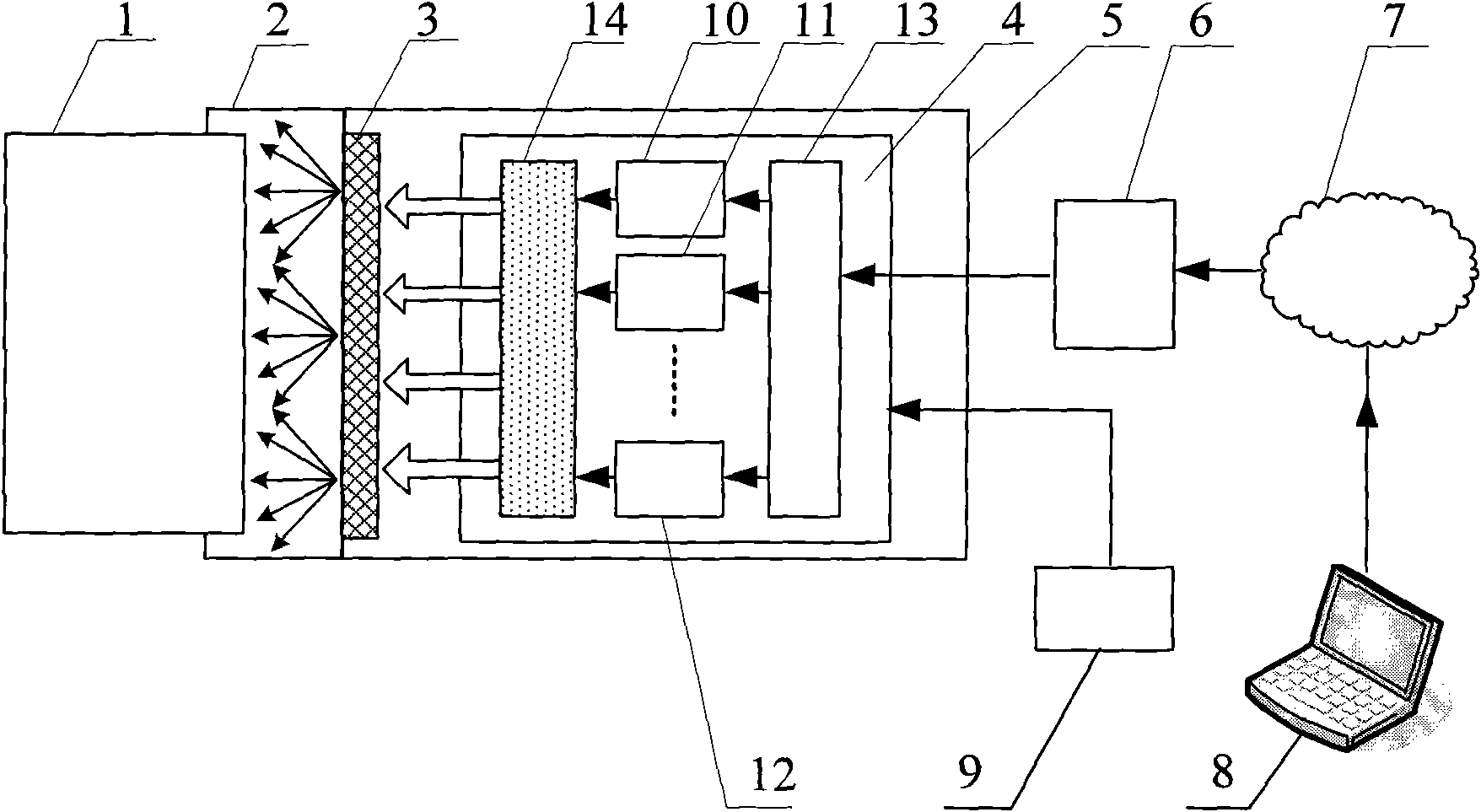

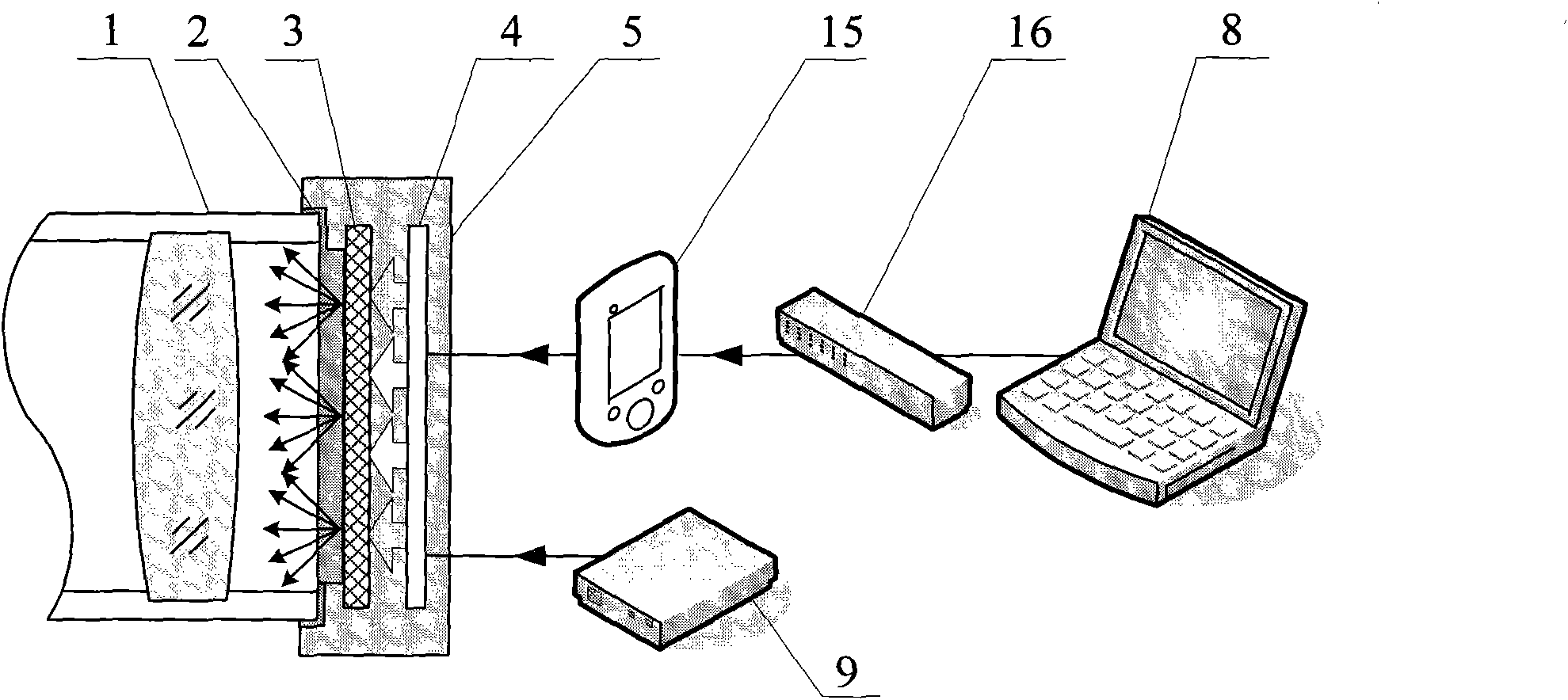

[0042] This embodiment is aimed at the multi-spectral uniform surface light source of the camera under test with a clear aperture of 150mm, which can generate uniform light-emitting surfaces with four spectrums of red, green, blue and near-infrared.

[0043] like image 3 As shown, the multi-spectral uniform surface light source includes a card mounting interface 2, a uniform light system 3, a multi-spectral light source circuit board 4, a casing 5, 15-industrial control human-machine interface, a switch 16, a computer 8, and a power supply 9.

[0044] in:

[0045] The clamping interface 2 is connected with the casing 5, and its inner dimension is the same as the outer dimension of the light inlet 1 of the object under test, so that the entire surface light source can be fixed on the light inlet 1 of the object under test.

[0046] The uniform light system 3 is installed on the light outlet of the casing 5 and is located between the light inlet 1 of the object under test and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com