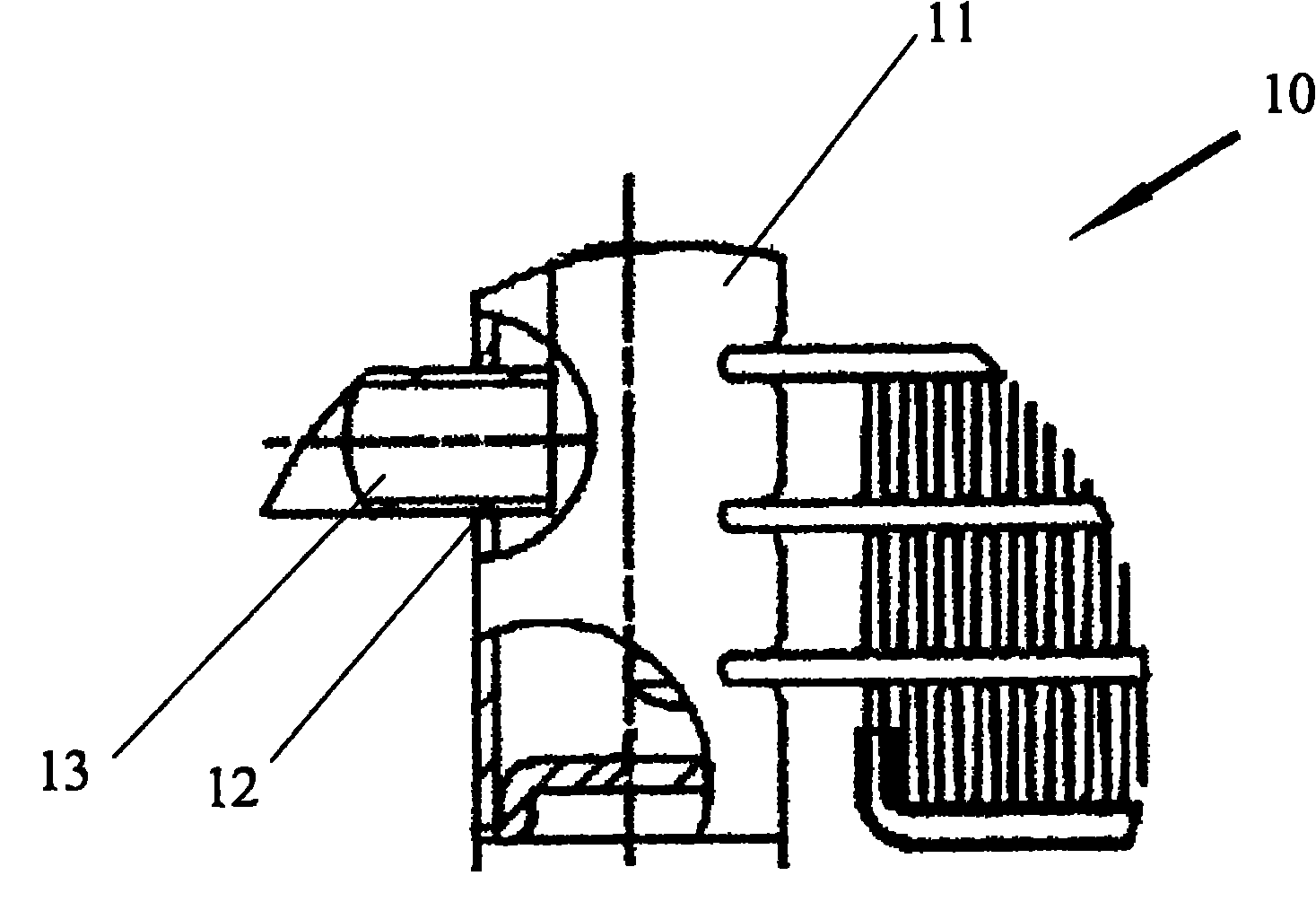

Pipe joint structure

A pipe joint and pipe turning technology, which is applied in the field of pipe joint structure of heat exchangers, can solve the problems of cost and weight increase, high processing cost, and more materials, and achieve the effects of weight reduction, welding strength increase, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

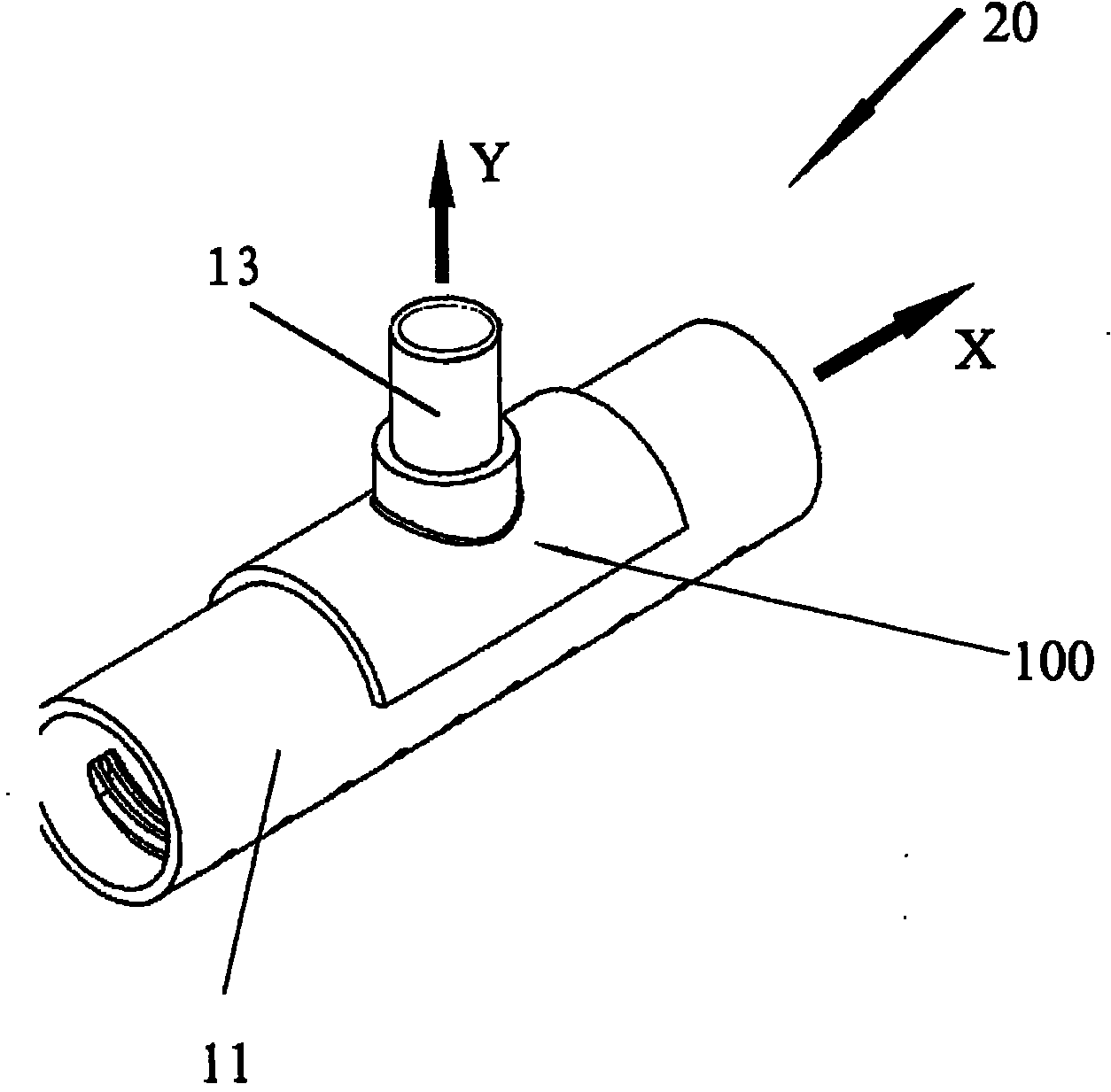

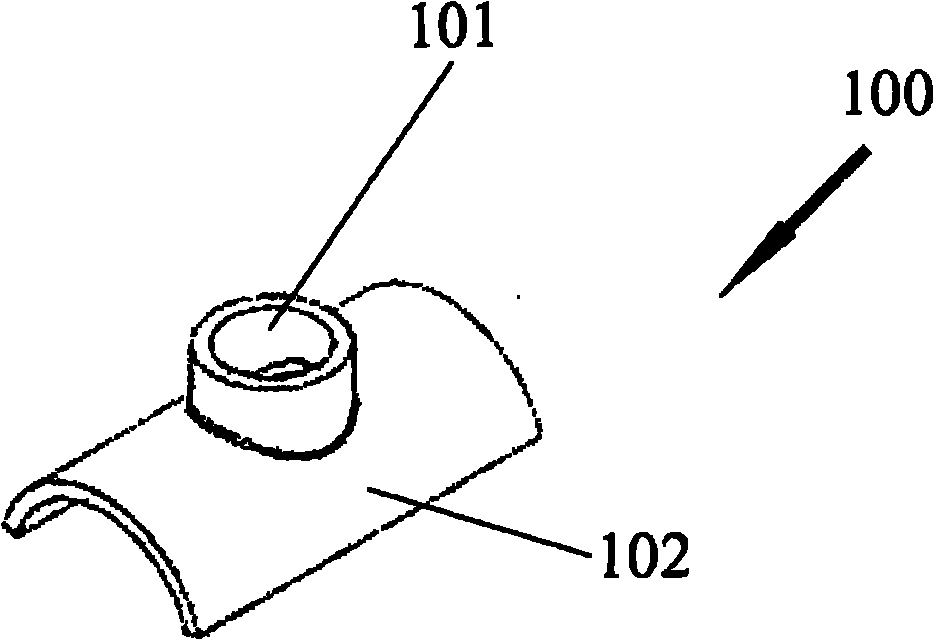

[0029] figure 2 is a perspective view of the pipe joint structure 20 according to the first embodiment of the present invention. The pipe joint structure 20 includes a manifold 11, an inlet and outlet pipe 13 and a pipe joint 100, wherein the manifold 11 is along a first direction (such as figure 2 The x-direction shown in ) transport fluid, the fluid includes but not limited to heat exchange medium such as water, oil, the header 11 has a through hole (not shown) formed in its side wall for Transversely communicate with other pipelines; the inlet and outlet pipes 13 are along the second direction (such as figure 2 The y direction shown in ) transports fluid, usually the first direction is substantially perpendicular to the second direction; the pipe joint 100 is used to sealably engage with the header 11 and the inlet and outlet pipes 13, the pipe joint 100 is hollow, and can It includes a first joint portion 101 that is jointed with one end of the inlet and outlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com