A continuous casting crystallizer centering measuring device

A technology of continuous casting mold and measuring device, which is applied in the directions of measuring ruler, measuring point mark, movable mark, etc., to achieve the effects of convenient operation, saving adjustment time and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

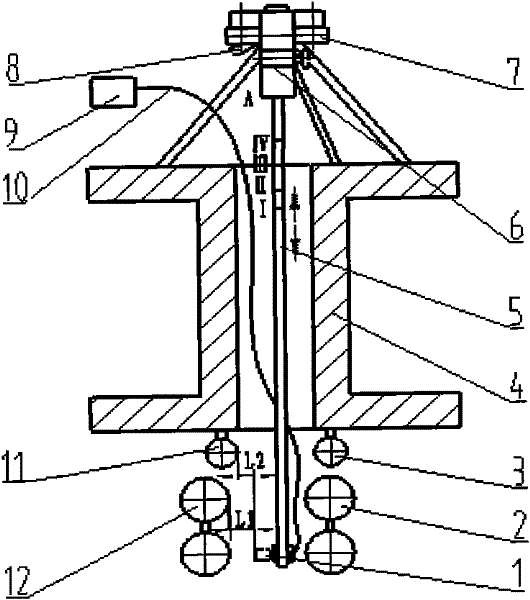

[0023] A continuous casting crystallizer centering measuring device and a measuring method thereof. The structure of the device is as figure 1 Shown: the device includes a sensor 1, a detection rod 5, a sliding device 6, a support adjustment frame 7 and a digital display table 9. The mounting plate 18 is fixed on the housing 13 in the sliding device 6, the lower plane of the mounting plate 18 is perpendicular to the center line of the housing 13, and the mounting plate 18 is fixed on the platform supporting the adjustment frame 7 by fastening bolts; It is installed in the housing 13 concentrically with the worm wheel 16 , and the sensor 1 is installed at the lower end of the detection rod 5 , and the sensor 1 is connected with the digital display meter 9 through the cable 10 .

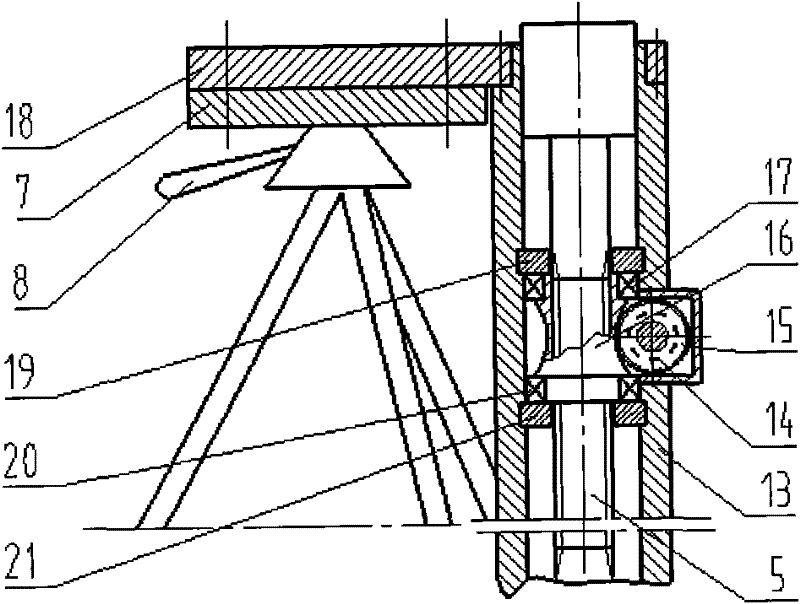

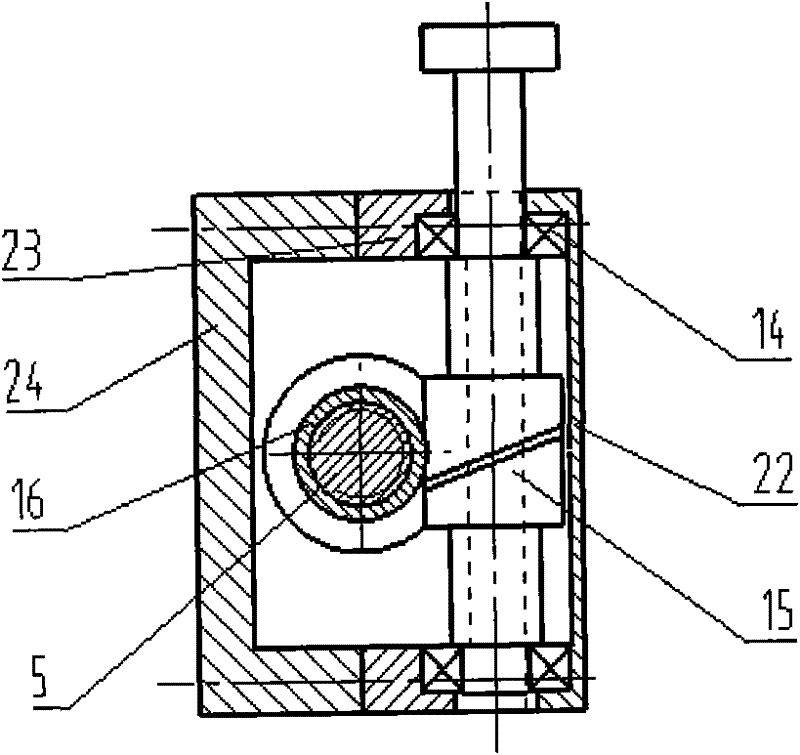

[0024] The structure of the sliding device 6 is as figure 2 , ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com