Bevel edge type liquid level measurement method and device based on isosceles right triangular prism

A liquid level measurement device, isosceles right angle technology, applied in the direction of measuring device, liquid/fluid solid measurement, lubrication indicating device, etc., can solve the problems such as difficult system error, and achieve the effect of small precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

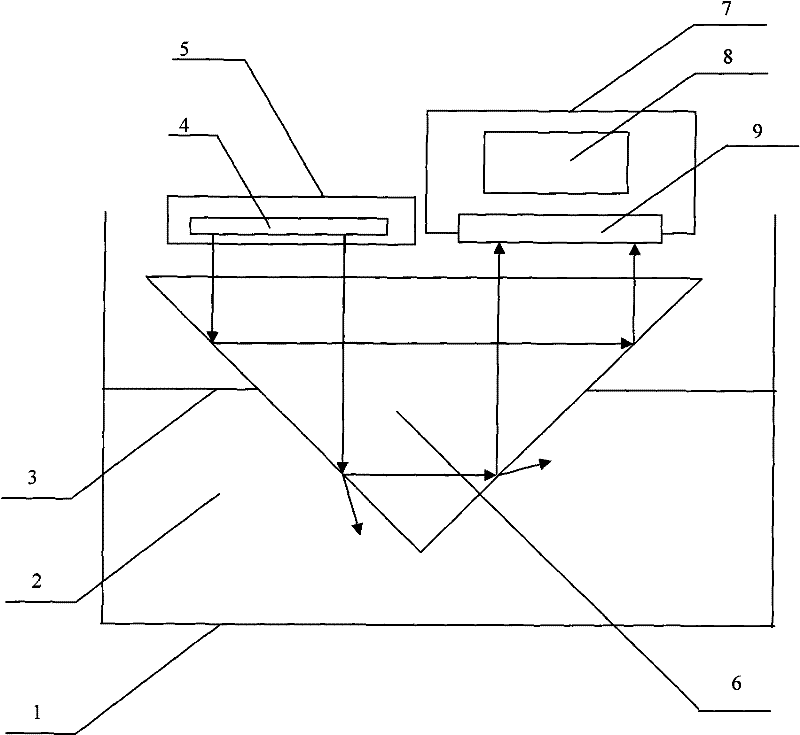

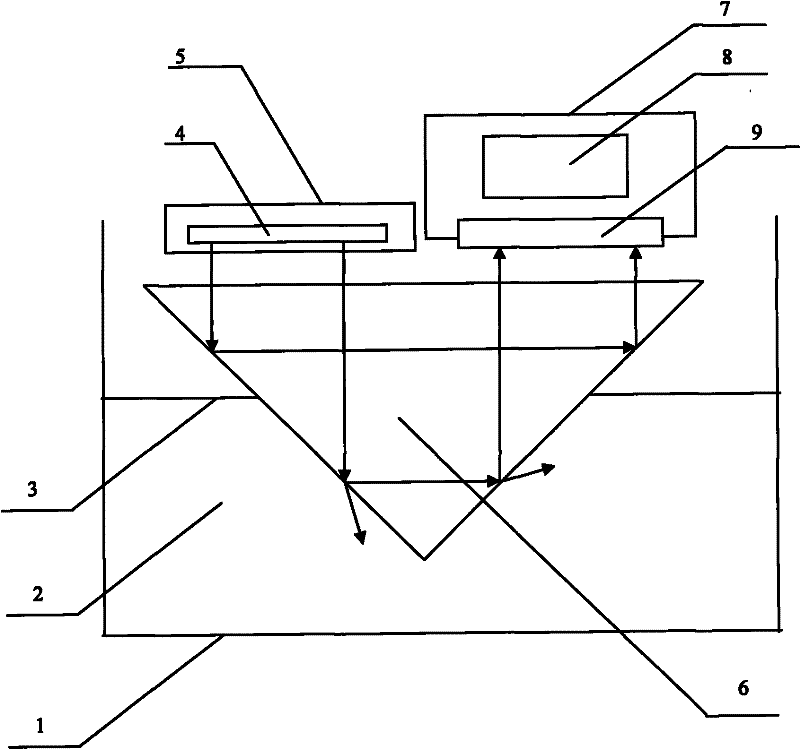

[0015] combine figure 1 The hypotenuse liquid level measuring device based on the isosceles rectangular prism includes a line light source 4 and a transparent protective cover 5, an isosceles rectangular prism 6, an airtight box 7, a linear array CCD9, and a circuit unit 8 (including: a linear array CCD9 drive circuit , data acquisition and processing circuit and data transmission circuit), the linear array CCD9 is embedded in a slot whose width and length are slightly larger than the width and length of the CCD9 chip on a certain side of the airtight box 7 and is slotted on both sides inside and outside the airtight box 7 Seal the gap with the CCD9, while ensuring that the protective glass of the CCD9 protrudes slightly from this side of the airtight box 7, and the line light source 4 and the linear array CCD9 are arranged above the hypotenuse plane of the prism 6 and parallel to the plane. At the same time, it is required that the line light source 4 and the linear array CCD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com