Kelvin probe force microscopy and measuring method thereof

A Kelvin probe force and microscope technology, which is applied in scanning probe microscopy, measuring devices, scanning probe technology, etc., can solve the problems of Kelvin probe force microscope application limitations and achieve the goal of improving spatial resolution and sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

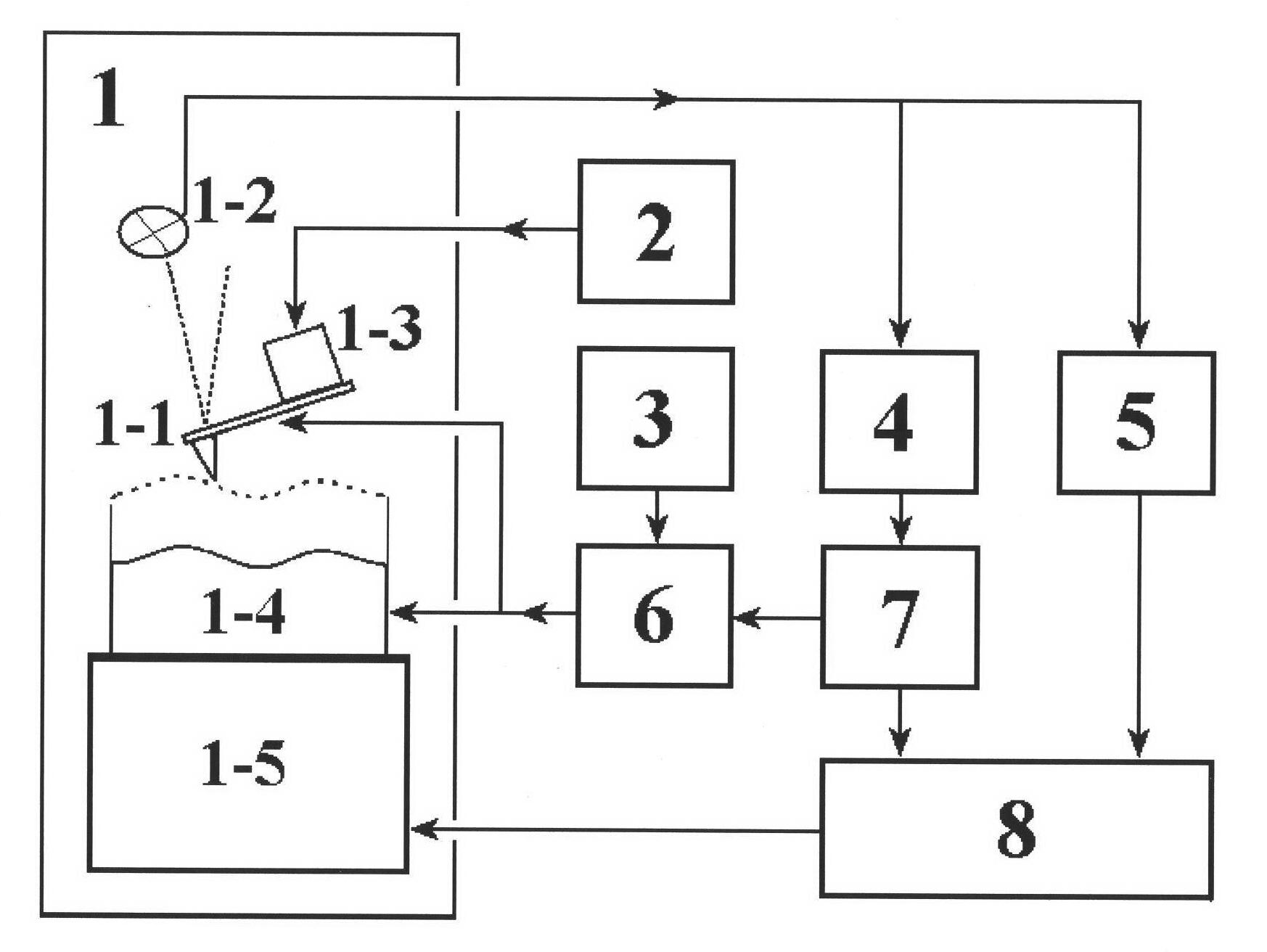

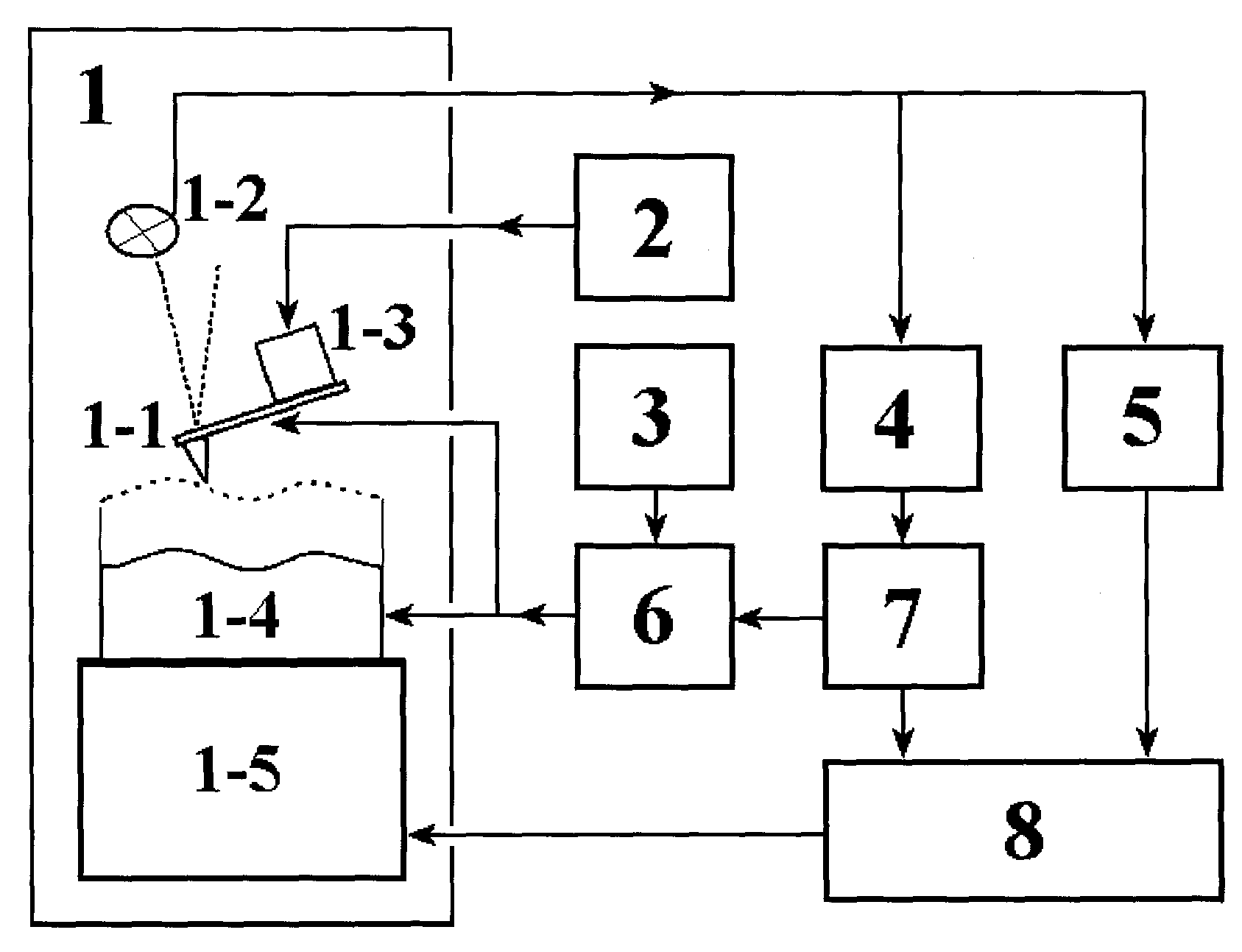

[0027] The structure of the present invention is as attached figure 1 As shown, it includes scanning head 1, low-frequency voltage signal generator 2, high-frequency voltage signal generator 3, high-frequency vibration signal detector 4, low-frequency vibration signal detector 5, high-frequency voltage and compensation voltage signal superimposer 6, Kelvin Feedback controller 7, controller 8, wherein the scan head 1 includes a conductive microcantilever probe 1-1, a probe position sensor 1-2, a piezoelectric vibrator 1-3, a sample 1-4, and a piezoelectric scanner 1-5, the Kelvin feedback controller 7 is used as a compensation voltage controller, and the controller 8 is used as a main controller.

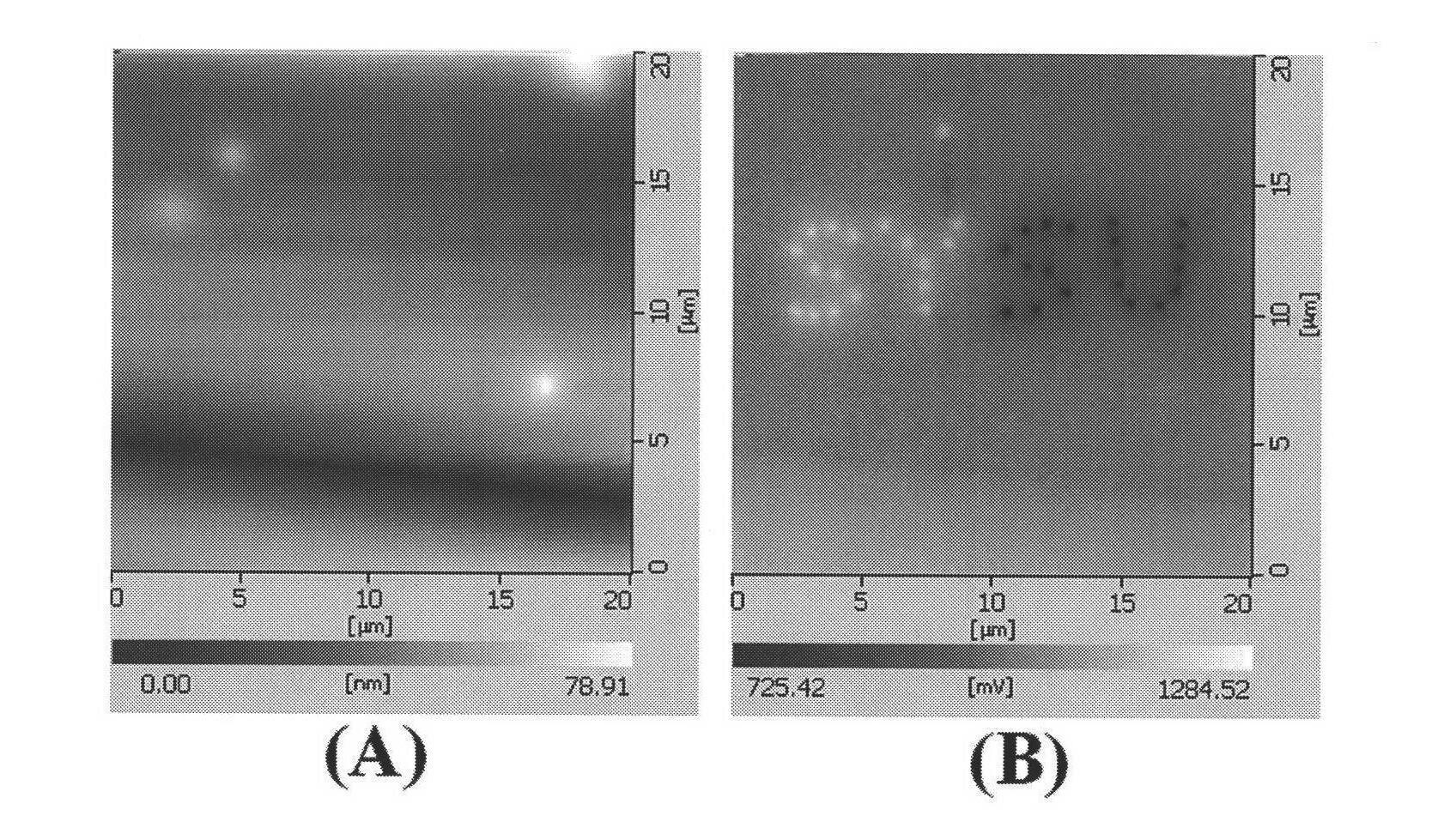

[0028] The measurement method of the invention does not affect the original measurement function of the static atomic force microscope. Before scanning the surface potentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com