Device and method for diffusion welding expansion measurement based on quenching dilatometer

A technology of diffusion welding and dilatometer, which is applied in the direction of material thermal expansion coefficient, etc., can solve the problems of real-time measurement of diffusion welding expansion measurement, etc., and achieve the effect of simple and easy transformation method, improved performance, and expanded application functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

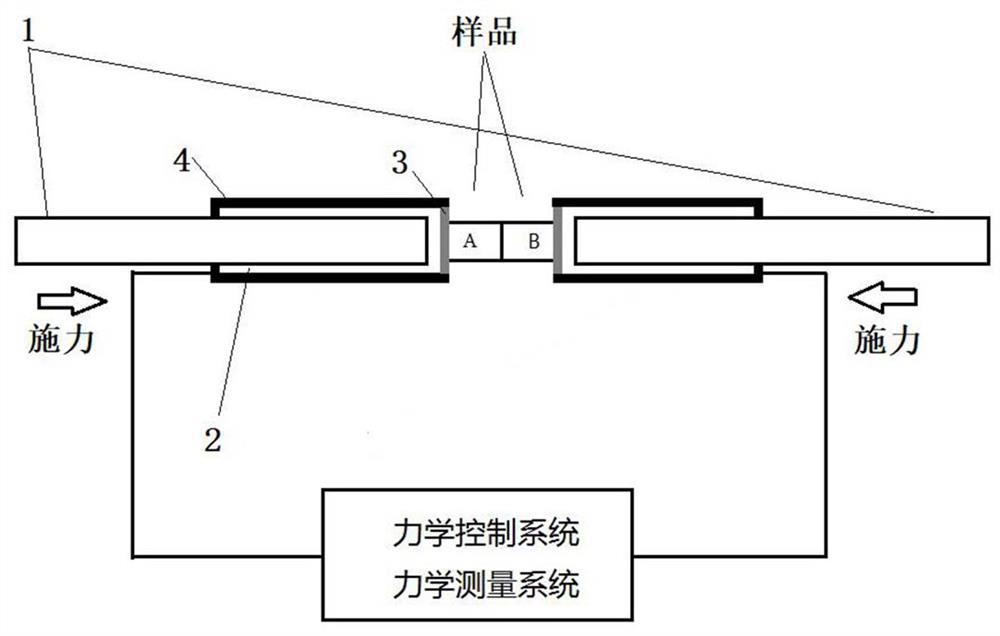

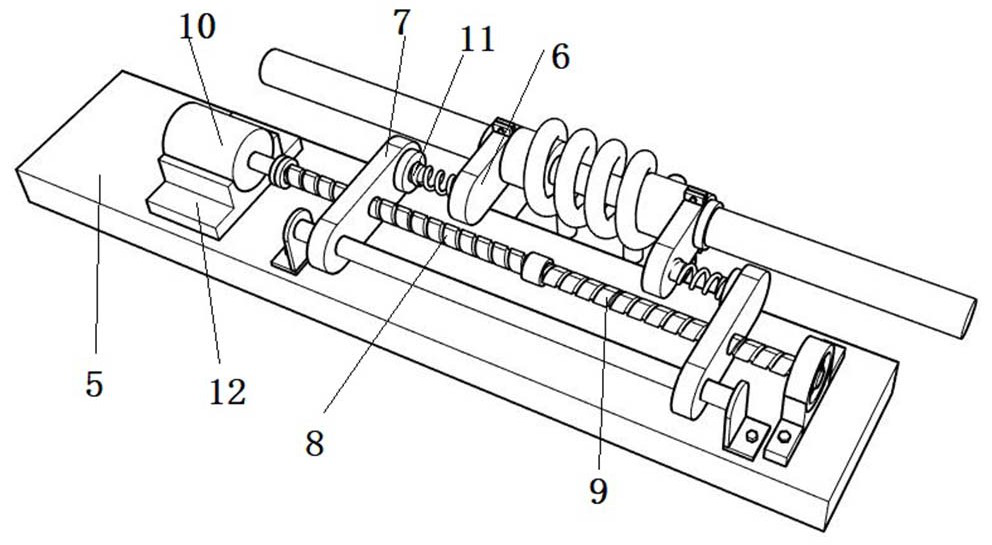

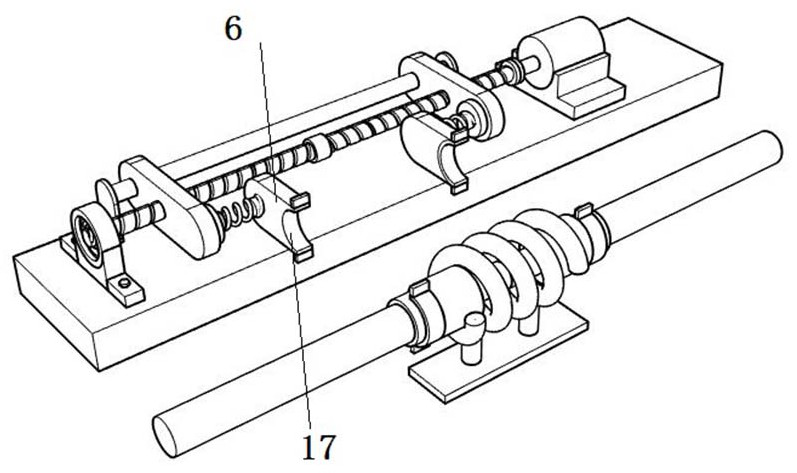

[0049]Example: Detected by L78 quenching thermal dilatometer of LINSEIS, the two standard samples for welding are usually Ф4mm×5mm; the sampling of the samples complies with the People’s Republic of China Ferrous Metallurgical Industry Standard YB / T5127-2018 "Critical Point Measurement of Steel Expansion" The requirements mentioned in 6 Sampling Requirements and 7 Sample Requirements in the Law; the diameter of the support mandrel is the standard Ф4mm, the inner diameter of the unilateral casing part is Ф4mm, the outer diameter is Ф10mm, and the length is 50mm. The casing part is in close contact with both ends of the test sample under the force of the quenching dilatometer support, and the sample is coaxial with the support ejector rod of the additional casing part 2 . The main body material of the sleeve part 2 is made of tungsten carbide, which is used for pressure transmission; the top part of the sleeve part 2 is covered with a tantalum layer 3, which is used to isolate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com