Printed wiring board

A printed circuit board and circuit technology, which is applied in printed circuit, printed circuit, printed circuit manufacturing, etc., can solve problems such as poor connection, easy cracks, easy to break the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0098] (1) First, a circuit board (core portion) as a unit constituting a multilayer printed wiring board is fabricated. This circuit board is a substrate that becomes the center of lamination among a plurality of insulating layers to be laminated, and a double-sided copper-clad laminate 10 obtained by laminating prepreg cloth and copper foil and heating and pressing is used as a starting material (see FIG. 4 (a)), this prepreg cloth is obtained by impregnating glass fiber cloth with epoxy resin and making it a B-stage.

[0099] The insulating resin substrate 12 has a thickness of 300 μm, and the copper foil 14 has a thickness of 3 μm. The copper foil of this laminated board uses copper foil with a thickness greater than 3 μm, and the thickness of the copper foil is adjusted to 3 μm by etching.

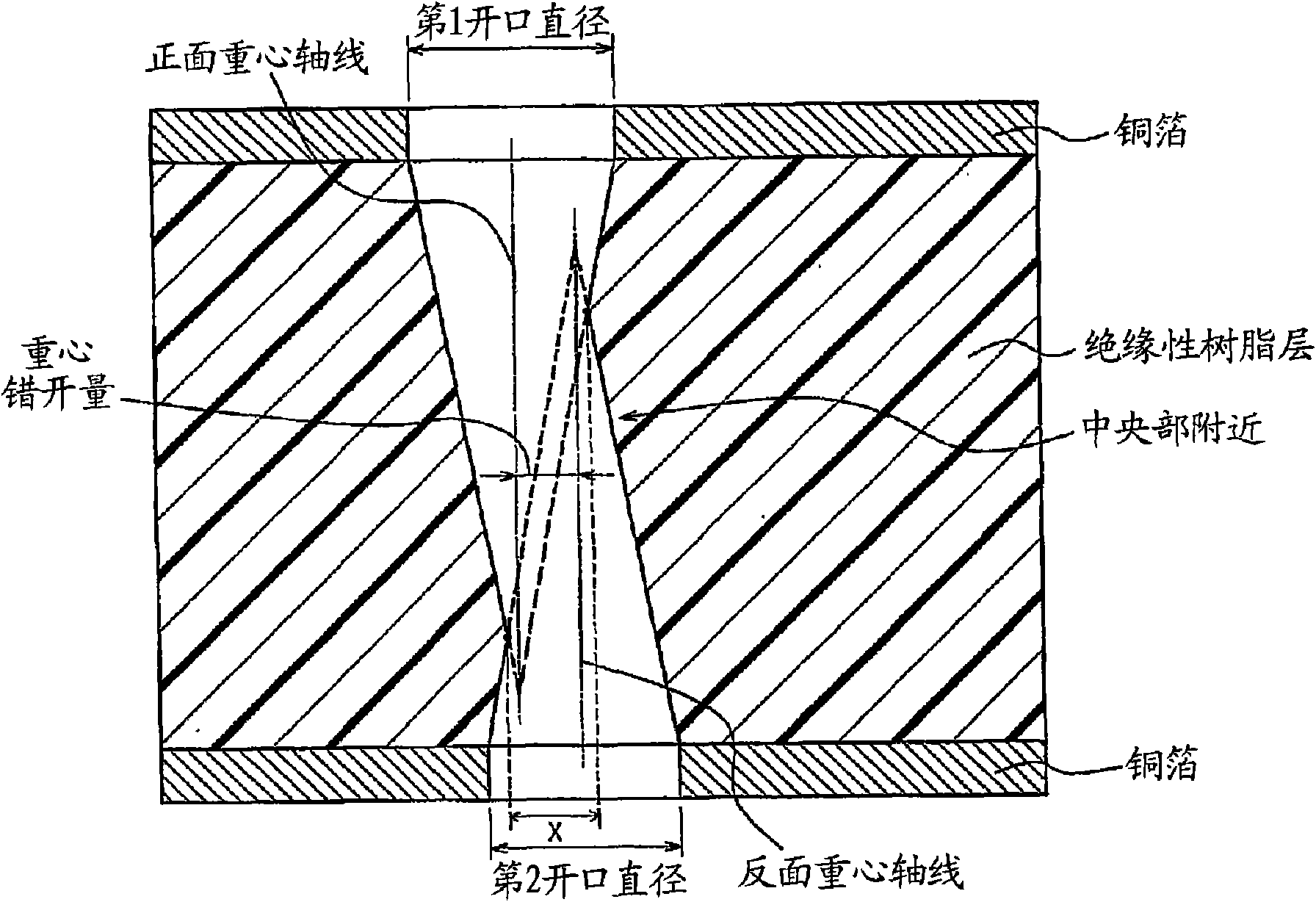

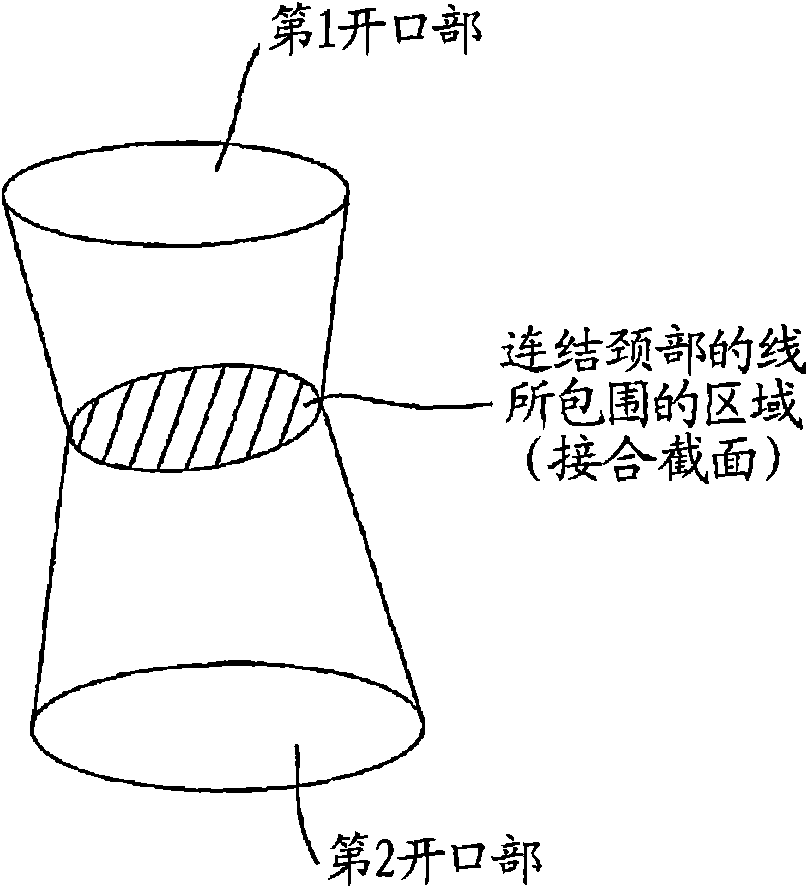

[0100] (2) Carbon dioxide gas laser irradiation is performed on a predetermined position on one surface of the double-sided circuit board 10 to form the first opening 16 (refer to FI...

Embodiment 1-2

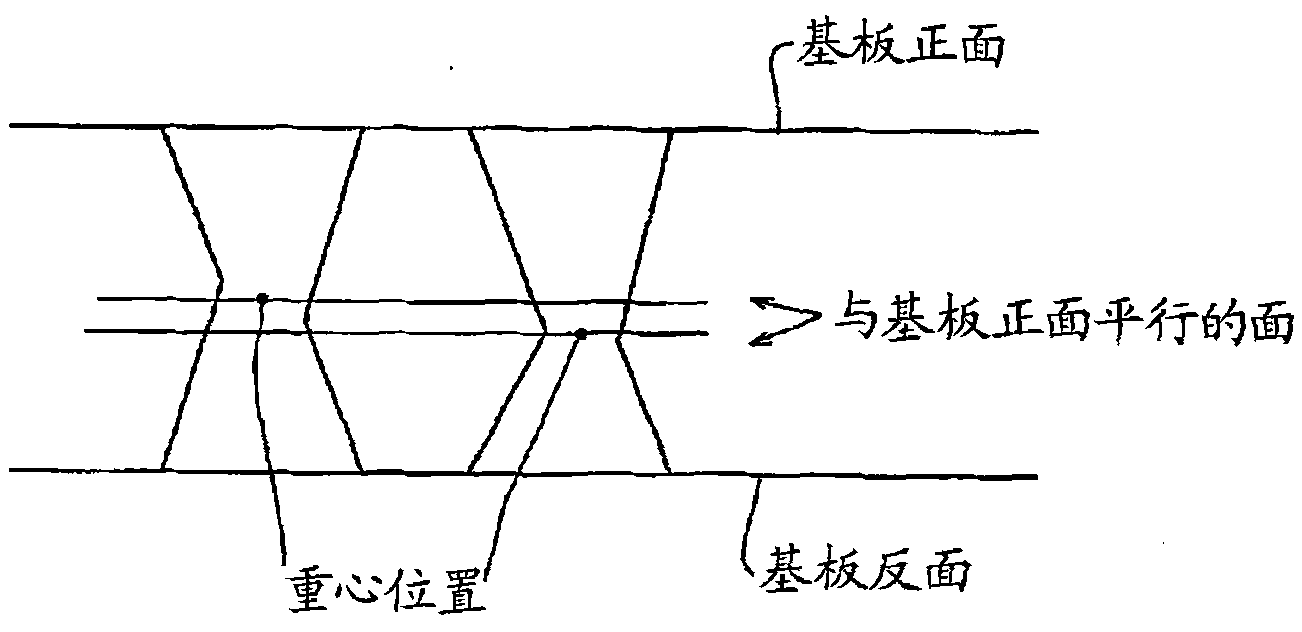

[0170] The through-hole 20 was formed in the same manner as in Example 1-1 except that the first opening 16 and the second opening 18 had a through-hole 20 with a center of gravity offset of 5 μm and a neck diameter of 76 μm by laser irradiation. A multilayer printed circuit board is produced.

Embodiment 1-3

[0172] The through-hole 20 was formed in the same manner as in Example 1-1 except that the center of gravity axis of the first opening 16 and the second opening 18 was shifted by 10 μm and the neck diameter was 80 μm by laser irradiation. A multilayer printed circuit board is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com