Liquid crystal device and improvement for tensile strength of liquid crystal screen with circuit board

A liquid crystal display, liquid crystal display technology, applied in static indicators, instruments, nonlinear optics, etc., can solve problems such as abnormal display, reduce product reliability and yield, and liquid crystal display products do not display, and improve quality. and reliability, tensile strength improvement, and the effect of reducing poor connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

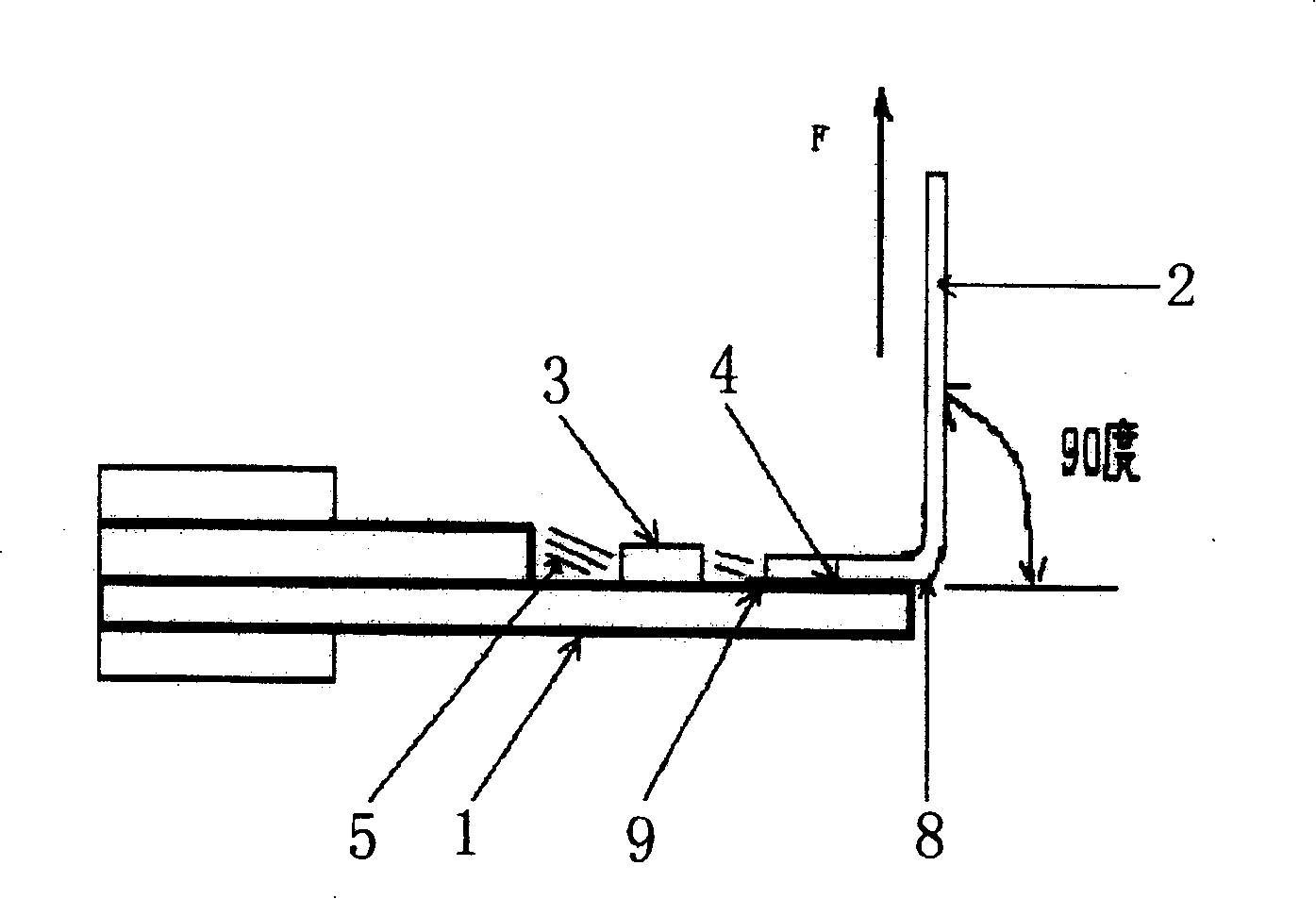

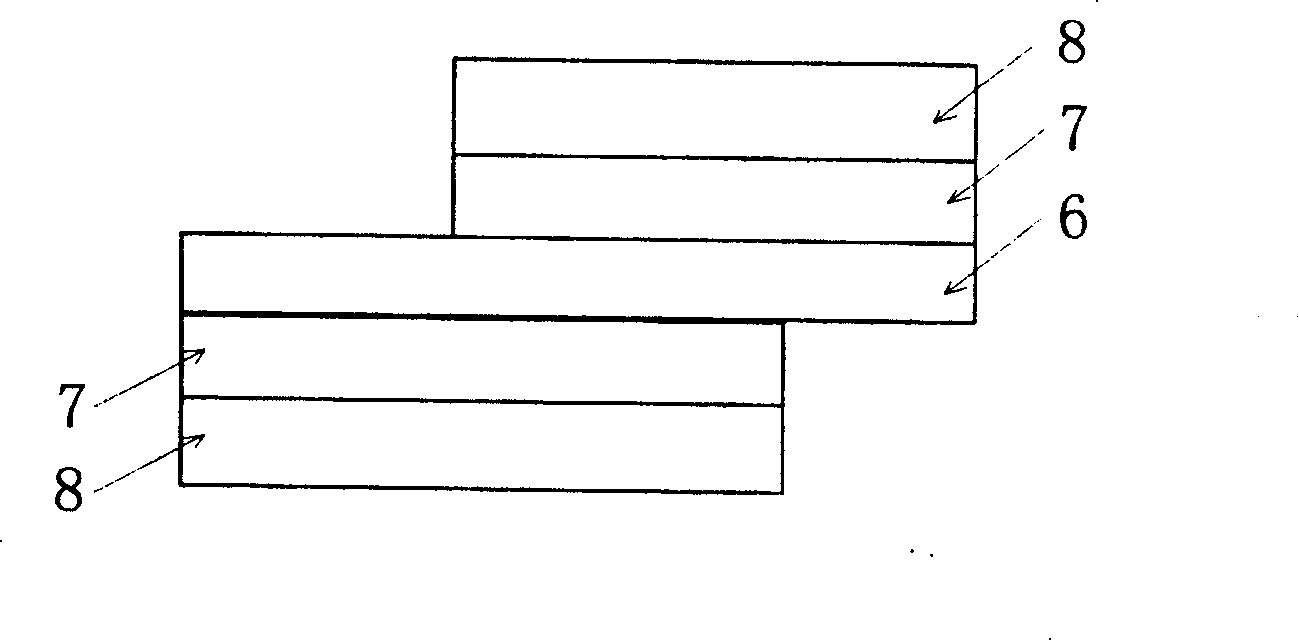

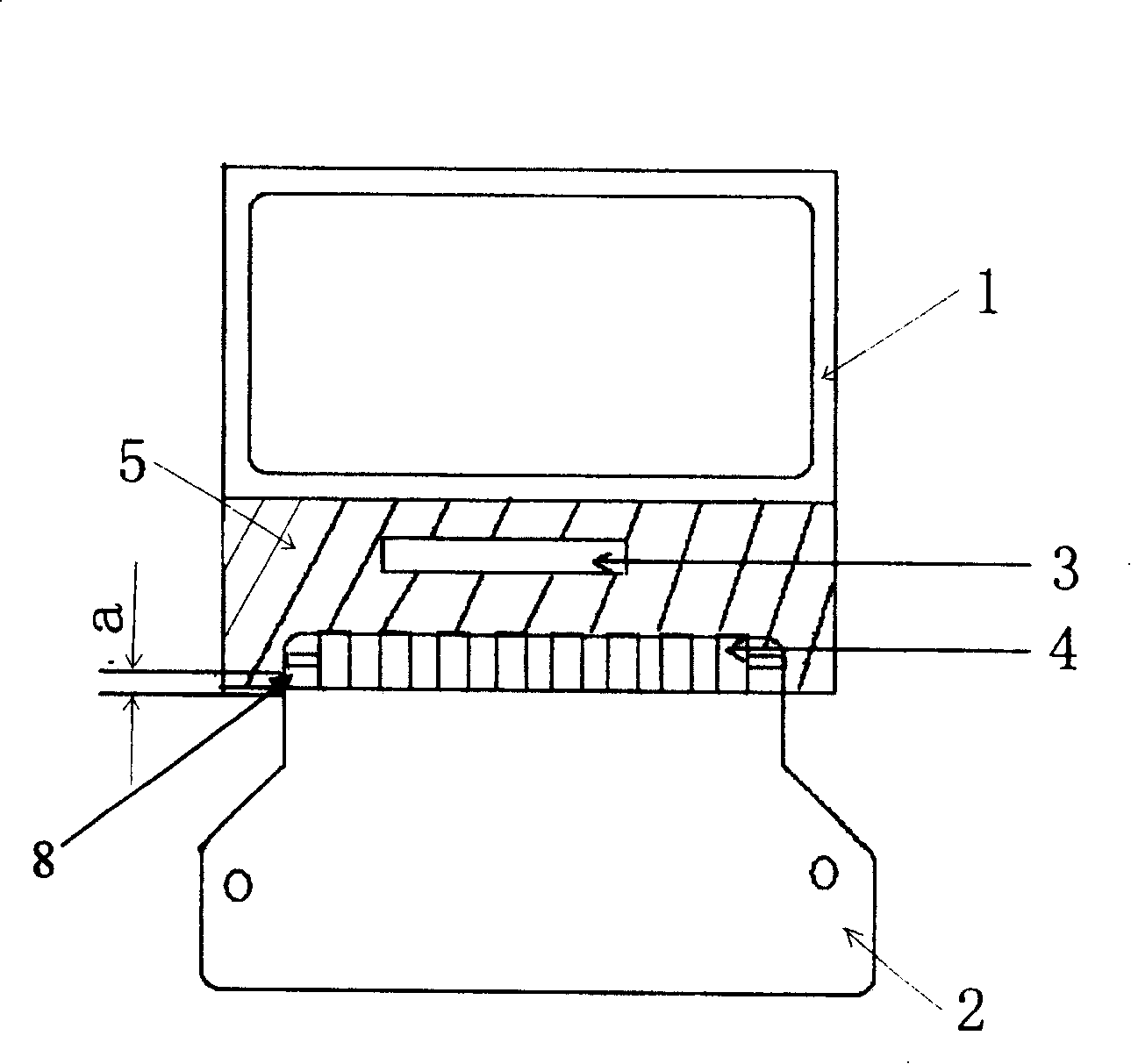

[0011] Embodiment one: if figure 1 with image 3 As shown, a liquid crystal display device includes a liquid crystal display 1, a flexible printed circuit board 2 and an IC drive circuit 3, an anisotropic conductive film 9 (ACF for short) is attached to the electrode of the liquid crystal display 1, and the flexible printed circuit The flexible gold finger 4 on the board 2 and the polyimide protective film 8 (PI protective film for short) located on the flexible gold finger 4 (see image 3 ) is hot-pressed on the electrodes of the liquid crystal display 1, wherein the length of the flexible gold finger 4 on the flexible printed circuit board 2 is selected to be between 0.1 and 1.0 mm, and the polyimide protective film 8 is hot-pressed on the liquid crystal display The width dimension on 1 is between 0.1 and 1.0mm.

[0012] Adopt above-mentioned embodiment, the tensile strength of FPC material can reach more than 800~1000g / cm; The flexible golden finger that has PI protectiv...

Embodiment 2

[0014] Embodiment two: if Figure 1 to Figure 3 As shown, a method for improving the tensile strength of a liquid crystal display with a flexible printed circuit board: comprises the following steps: 1) ACF material (anisotropic conductive film) is attached on the electrode of the liquid crystal display 1, 2 ) The flexible gold finger 4 on the FPC material is selected from a length dimension range of 0.1 to 1.0 mm, and the PI protective film with a width of 0.1 to 1.0 mm on the flexible gold finger and the flexible gold finger 4 of the flexible printed circuit board 2 pass through TAB The pressing machine is hot-pressed on the LCD screen with ACF material, and the range of each process parameter is: hot-pressing temperature (set value): 210±10°C, hot-pressing time: 5~7 seconds, hot-pressing pressure (set value) value): 0.45~0.5MP; 3) Silicone gel 5 is coated on the upper surface of the flexible gold finger 4 and the surface of the electrode of the liquid crystal display that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com