PCB with interconnected blind holes and processing method thereof

A technology for interconnecting blind holes and processing methods, which is applied in the field of communication and can solve the problems of inability to clean, difficult to clean, and residual liquid medicine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

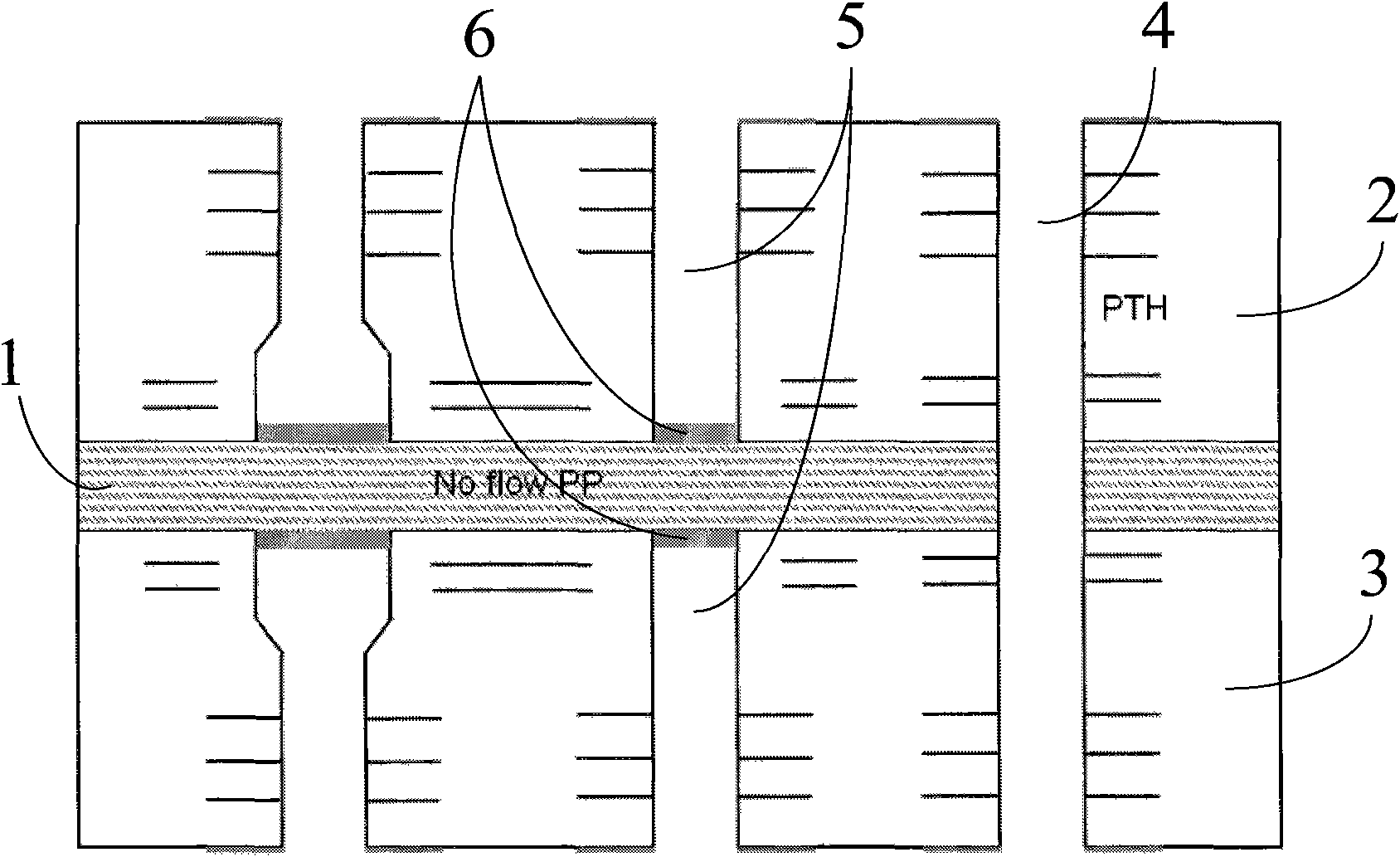

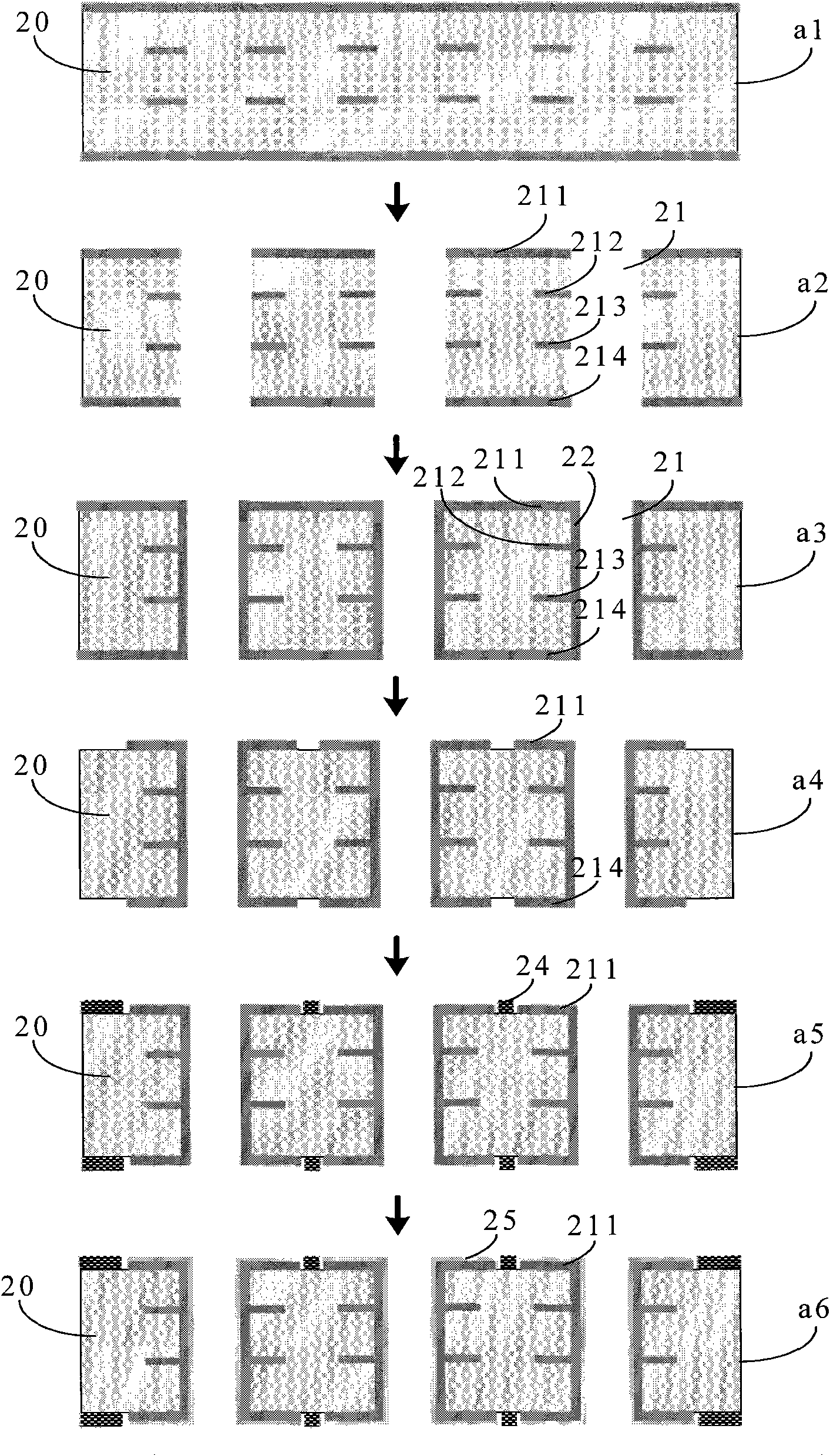

[0021] The embodiment of the present invention provides a PCB processing method with interconnected blind holes, which can be used to process PCBs with interconnected deep blind holes on both sides. The method is to convert two multi-layer sub-boards into a double-sided core board As a connection layer, and cooperate with two prepregs, two prepregs are arranged between two multi-layer sub-boards, and a double-sided core board is arranged between the two prepregs for pressing to obtain double-sided interconnected deep blind holes. PCB, the specific process of the method is as follows Figure 2-Figure 5 shown, including the following steps:

[0022] A. Processing multi-layer sub-boards: use at least two multi-layer sub-boards, process multiple through holes that are not electrically conductive on each multi-layer sub-board, and make the through holes become electrically conductive after electroplating through-holes, the outer layer circuit patterns are processed on the multi-la...

Embodiment 2

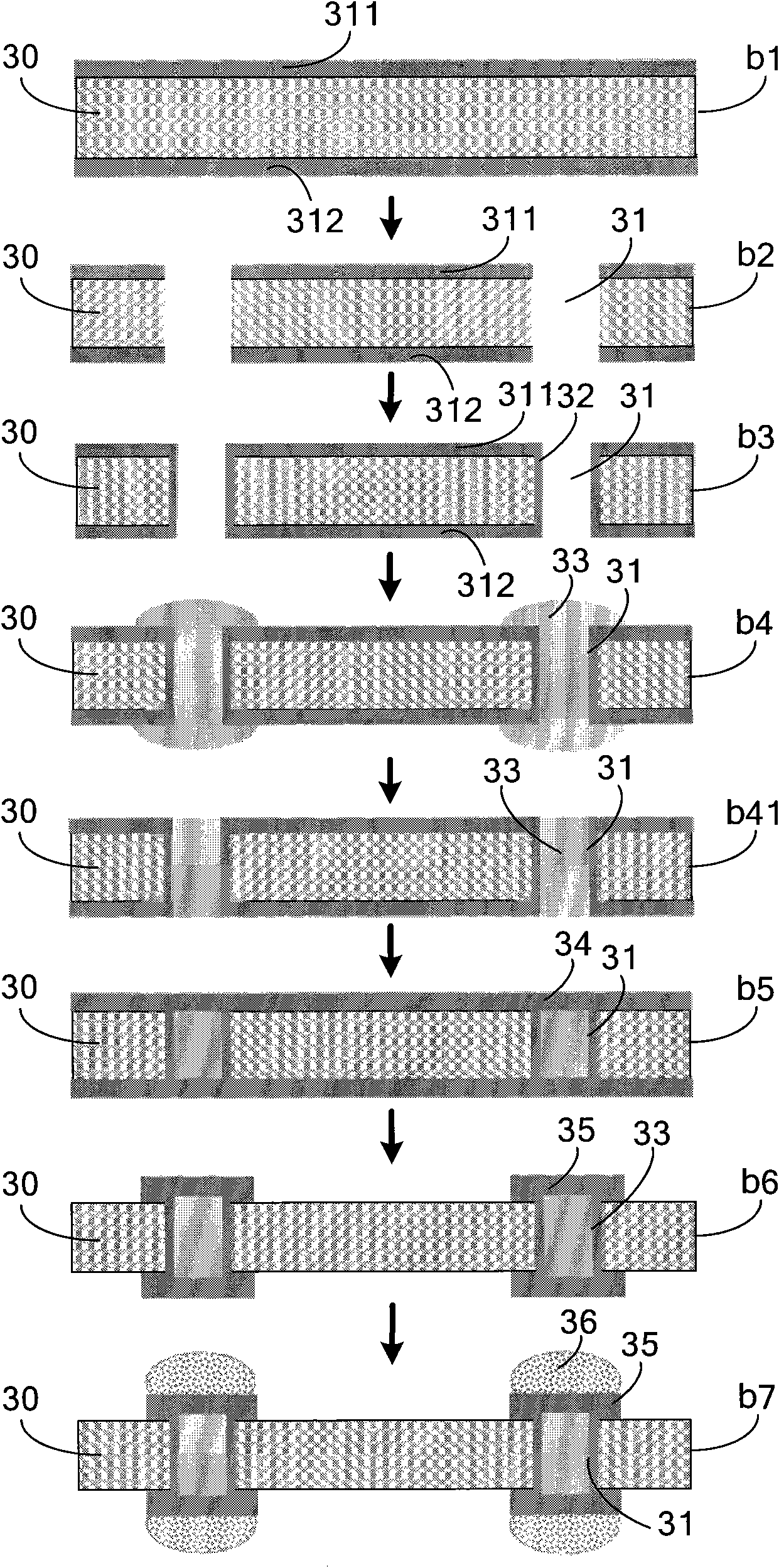

[0050] The embodiment of the present invention also provides a PCB prepared by the processing method of the above-mentioned embodiment 1, such as Figure 5 As shown, the PCB is a multi-layer structure formed by pressing at least two multi-layer sub-boards, at least two prepregs and at least one double-sided core board 30, and the outer layer of the multi-layer structure is two multi-layer sub-boards 20, 200 , a double-sided core board 30 in the middle, and prepregs 40, 400 between the two multi-layer sub-boards 20, 200 and the double-sided core board 30, respectively. In this PCB, a plurality of electrically conductive connecting through-holes 31 are provided on the double-sided core board 30, conductive bosses 35 are provided at both ends of each connecting through-hole, and multi-layer sub-boards 20, 200 are provided with a plurality of electrically conductive Conducted through holes, and form the outer layer circuit pattern, and the multi-layer sub-board after chemical proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com