Juicer

A technology for a juicer and a crushing mechanism, applied in the field of juicers, can solve the problems of affecting the juice yield, high motor speed, and short residence time, and achieve the effects of improving the juice yield, reducing the speed and reducing the juice foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

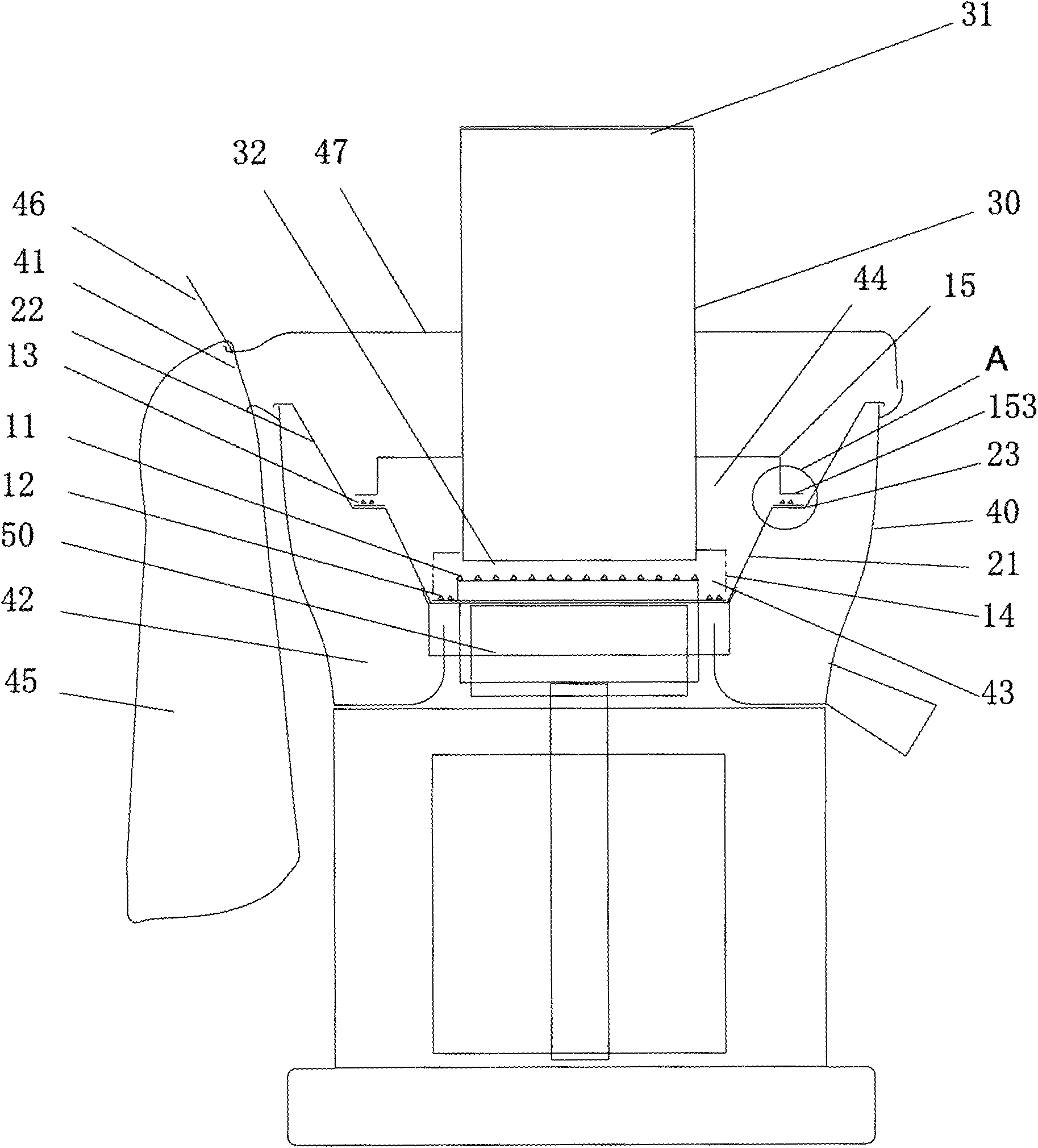

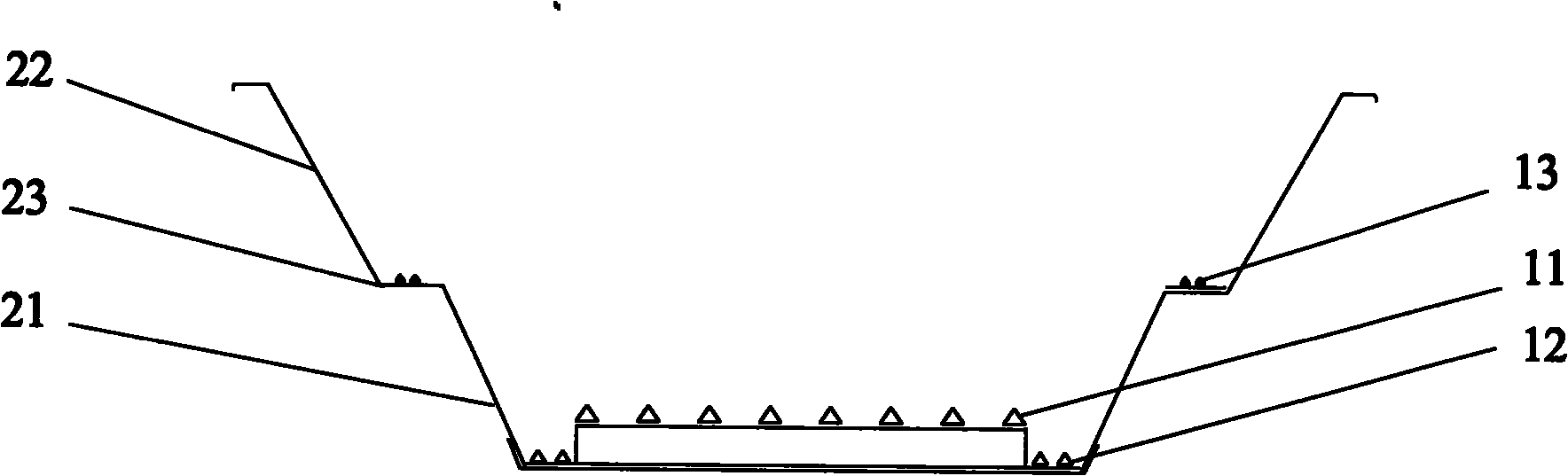

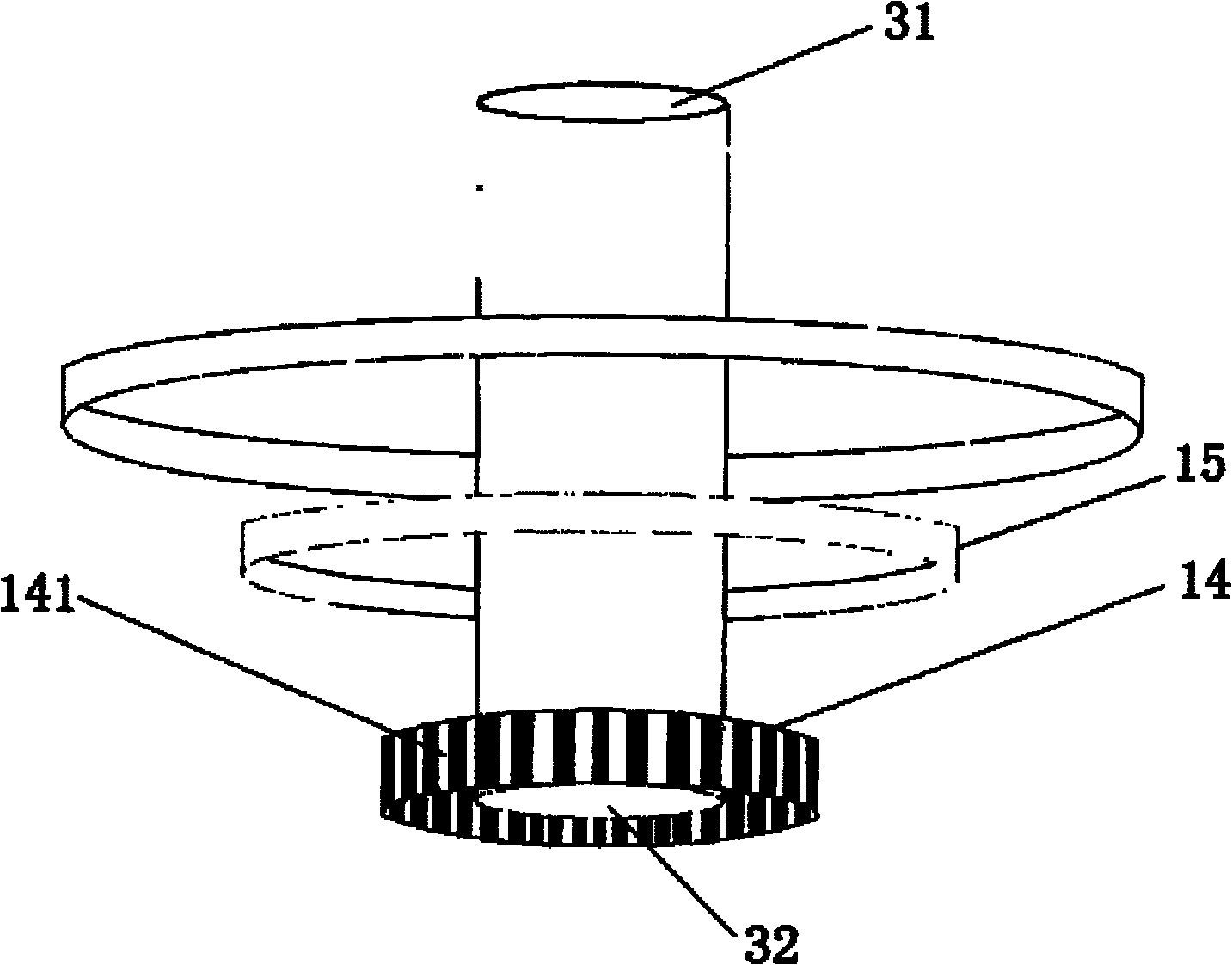

[0027] Such as Figure 1 to Figure 6 As shown, the juice extractor in this embodiment includes a crushing mechanism, a filter screen, a feeding cylinder 30, a driving device 50 for driving the crushing mechanism, a collector 40, and a slag outlet 41. The mouth 41 is located at the top of the inner cavity and communicates with the inner cavity. The slag outlet 41 is provided with an openable door 46 and a pomace bag 45 , and the pomace bag 45 is detachably hung on the slag outlet 41 . When there are few fruits and vegetables for squeezing the juice, the door 46 on the slag outlet 41 can be closed to directly squeeze the juice without using the pomace bag 45 to collect the pomace. Fruit residue bag 45 can be selected common environmental protection bag for use. The collector 40 can collect vegetable juice when the juice extractor is squeezing the vegetable juice; the collector 40 can also be used to collect soybean milk when squeezing soybean or five-grain soybean milk.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com