Three-degree of freedom under-actuated robot wrist device

An under-actuated, degree-of-freedom technology, used in manipulators, manufacturing tools, joints, etc., can solve the problems of complex mechanical structure, high cost and large volume, and achieve the effect of small size, low cost and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

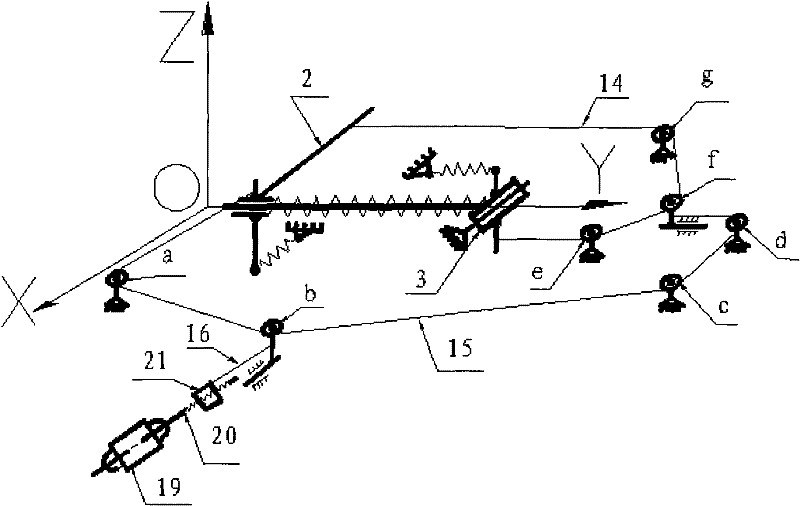

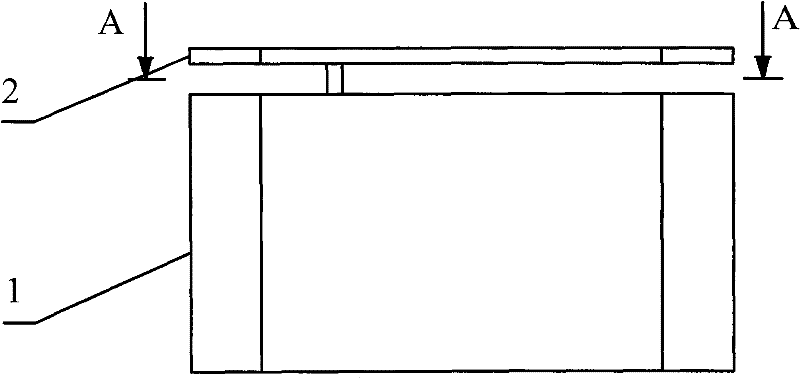

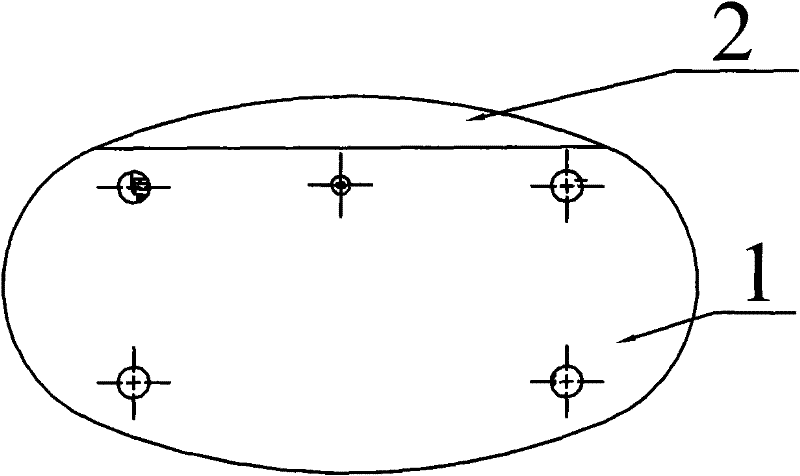

[0053] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , the three-degree-of-freedom underactuated robot wrist device includes a box body 1, an output end with three degrees of freedom and a power source input end; the power source is a single power source, which is connected to the box body through a rope 316; the output The end is an end link 2 connected to the box body 1; an underactuated system is installed in the box body 1, and the rope three 16 is connected to the end link 2 through the underactuated system; the linear motion of the rope three 16 is transmitted through the underactuated system, Drive the end link 2 to move in three degrees of freedom. The single power source can be that the output end of a motor 19 is connected with a screw mandrel 20, and the screw mandrel 20 is screwed with a nut sleeve 21, and the nut sleeve 21 is connected with the rope three 16.

Embodiment 2

[0054] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: see figure 1 , Figure 5 , Figure 6 , Figure 7 , the structure of the underactuated system is: the rope three 16 is connected to a sliding guide wheel b in the vertical direction, and after a rope two 15 bypasses the sliding guide wheel b in the vertical direction, one end goes around a fixed The guide wheel a is connected to the end connecting rod 2 and inserted into the lower end of the box, which can pull the end link 2 to swing, while the other end bypasses a fixed guide wheel 2 c and a fixed guide wheel 3 d and then connects to a horizontal The sliding guide wheel f in the direction can pull the sliding guide wheel f to move horizontally; after a rope-14 walks around the sliding guide wheel f in the horizontal direction, one end of the rope-14 walks around a fixed guide wheel 4e Connect one side of rotating connecting rod 2 to make rotating connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com