Glue spraying mechanism of perfect adhesive binding machine

A perfect binding machine and glue spraying technology, which is applied in the field of the glue spraying mechanism of the wireless perfect binding machine, can solve the problems of uneven gluing, irritating smell, affecting the quality of perfect binding, etc., and achieves uniform glue spraying, beautiful appearance, The effect of material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and embodiment.

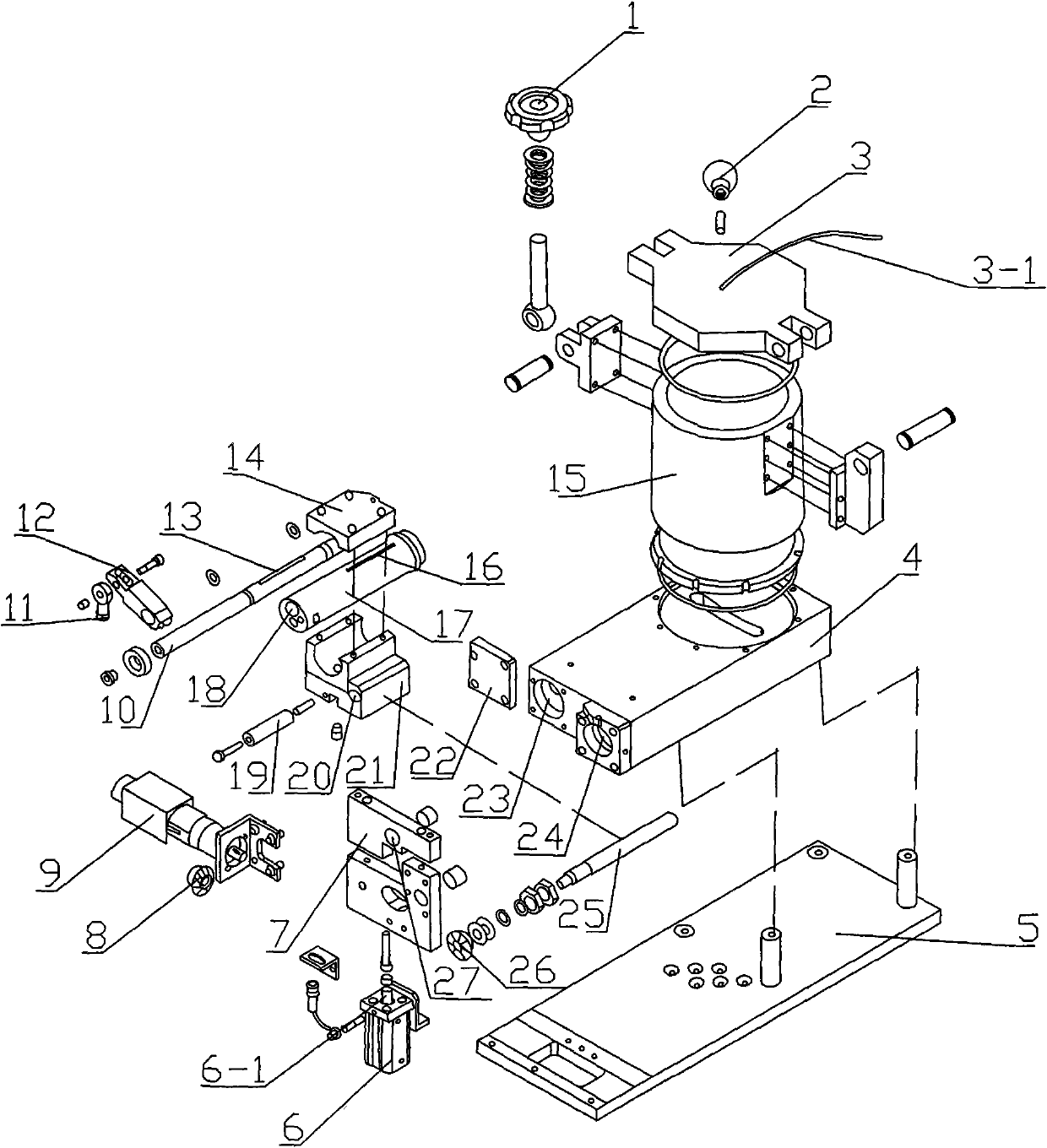

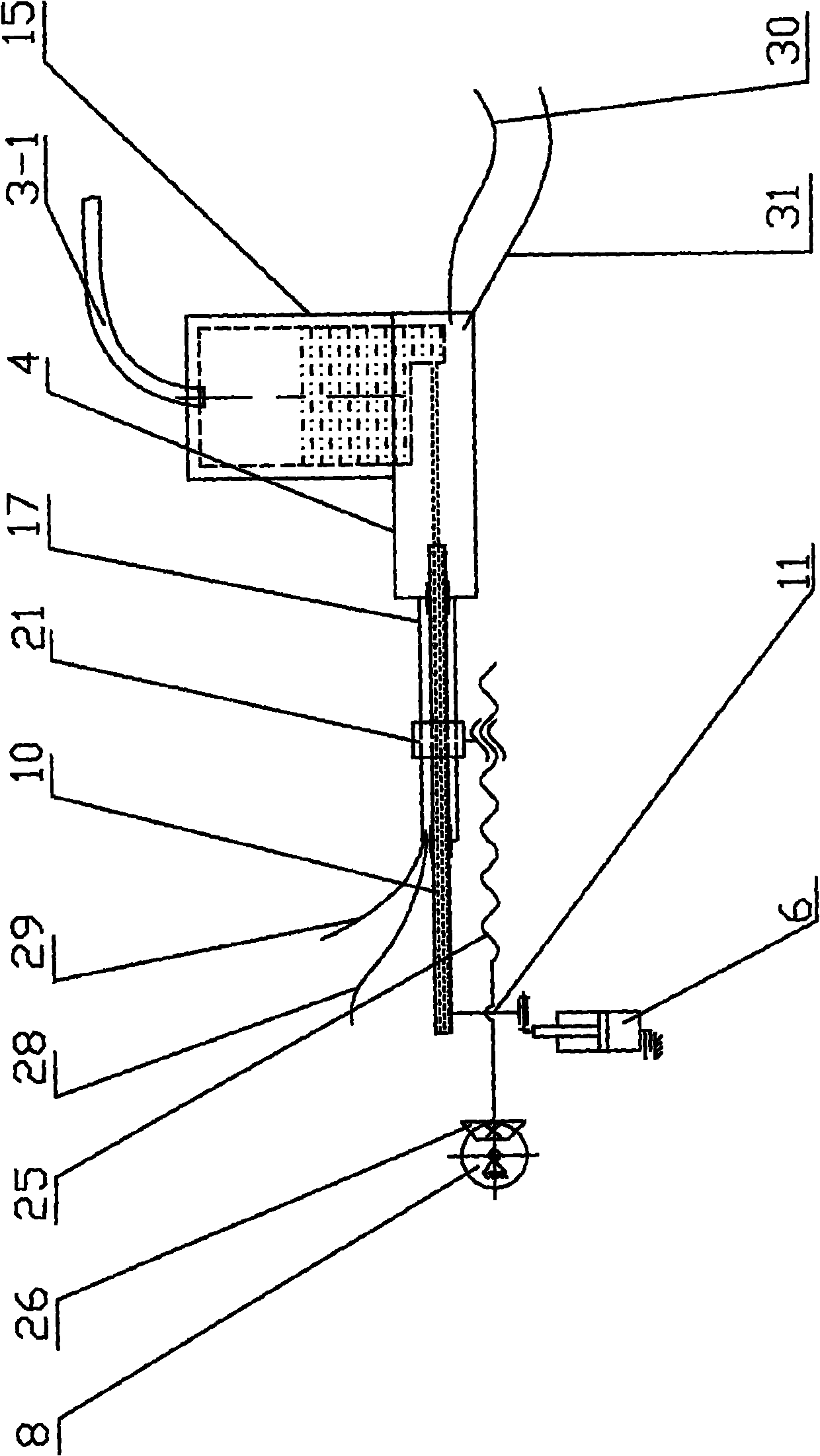

[0013] As shown in the figure, the present invention includes a glue applicator center plate 4 and a glue tank 15 arranged on the glue applicator center plate 4 . A first glue outlet 23 and a second glue outlet 24 are provided on the center plate 4 of the glue applicator. A cover 22 is covered on the second glue outlet 24 . The port of the first glue outlet 23 is equipped with an outer spray glue pipe 17 . The top of the outer glue spray pipe 17 is provided with an outer glue spray tank 16 . Inside the pipeline 18 of the outer glue hose 17, the inner glue hose 10 is sleeved. The inner glue spraying pipe 10 is provided with an inner glue spraying groove 13 . The internal spray glue pipe 10 communicates with the glue tank 15 through the first glue outlet 23 . In the state of glue spraying, the inner glue spraying groove 13 faces the outer glue spraying gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com