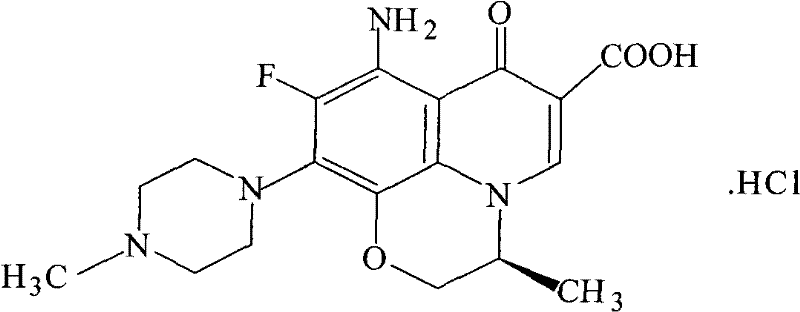

Preparation method of high-purity antofloxacin hydrochloride

A technology of sandacin and hydrochloric acid, which is applied in the field of preparation of high-purity Antofloxacin hydrochloride, can solve the problems of high production cost, unreachable purity, waste of raw materials, etc., and achieve the effect of low production cost and less waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is further illustrated below by way of examples.

[0009] (S)-9,10-difluoro-2,3-dihydro-3-methyl-8-amino-7-oxo-71H-pyrido[1,2,3-de][1,4 ] benzoxazine-6-carboxylic acid (abbreviated as amino levocarboxylate), N-methylpiperazine and pyridine are charged according to the weight ratio of 2.56kg: 4.9kg: 52kg, after stirring and dissolving, the steam is heated to reflux, and the heating temperature React at 115°C±2°C for 10 hours, evaporate pyridine under reduced pressure, put the residue into 10.8kg of ethanol, filter, wash the filter cake with ethanol, and dry under normal pressure or vacuum at 60-100°C for 8 hours to obtain crude Antofloxacin. Put the crude Antofloxacin obtained above and water into an enamel-jacketed reactor at a weight ratio of 2.68kg: 80kg, slowly add hydrochloric acid under stirring to make the pH of the solution 4.0 to 4.5, and keep it for 30 minutes. Filter through a pore filter, put it in a clean reaction kettle, slowly add am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com