Concrete stirring and mixing equipment

A technology for mixing and mixing concrete, applied in mixers, mixer accessories, cement mixing devices, etc., can solve the problems of raw material waste, affecting the production environment, etc., to reduce raw material waste, rinse thoroughly, and automatically rinse the mixing box and mixing rod. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

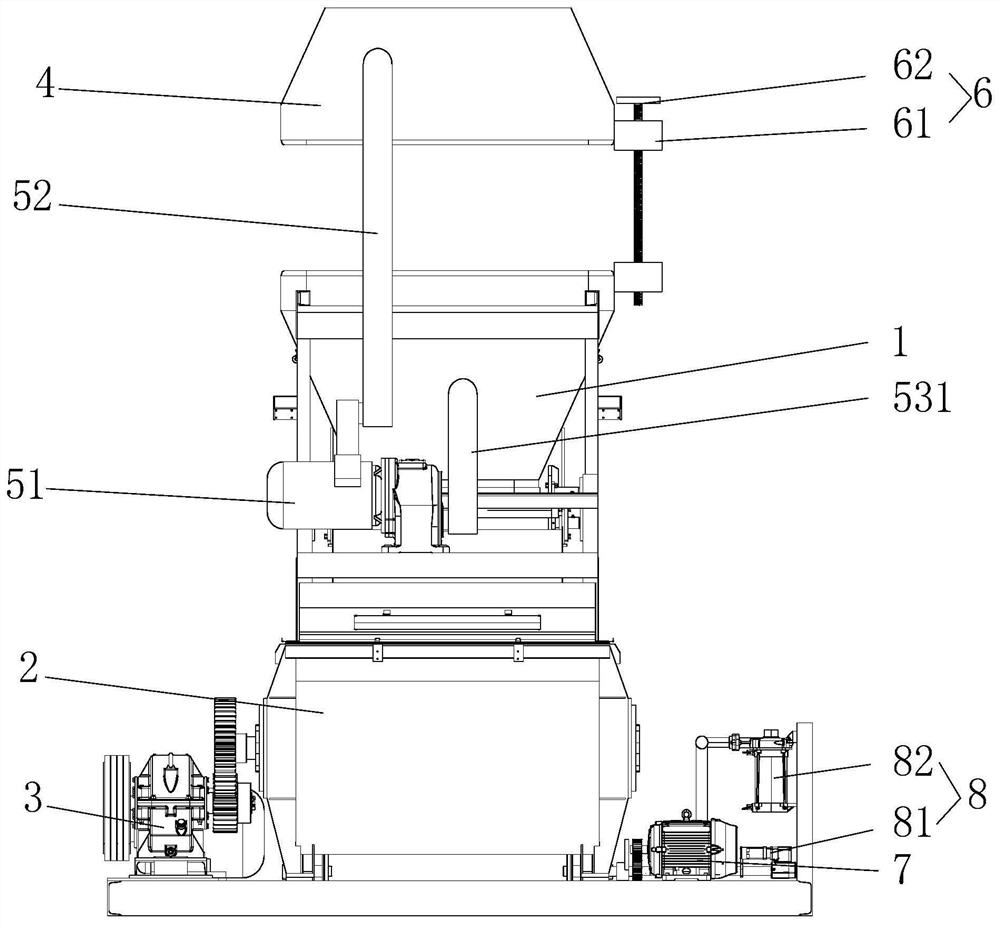

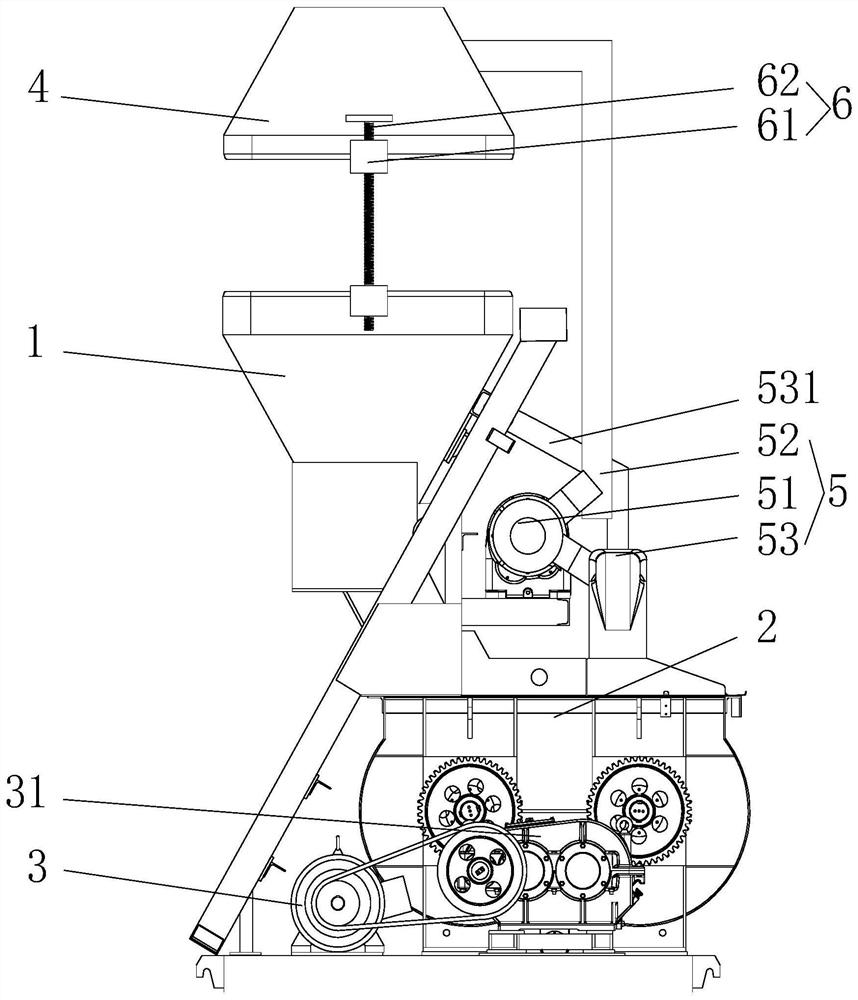

[0029] like Figure 1-5 As shown, the concrete mixing and mixing equipment includes a feed hopper 1, a mixing box 2, a dust removal mechanism 5 and a cleaning mechanism 8. A dust collection hood 4 is arranged above the feed hopper 1, and the dust collection hood 4 is connected to the feed hopper through a connecting piece 6. 1 is connected, and there is a gap between the suction hood 4 and the feed hopper 1 for feeding.

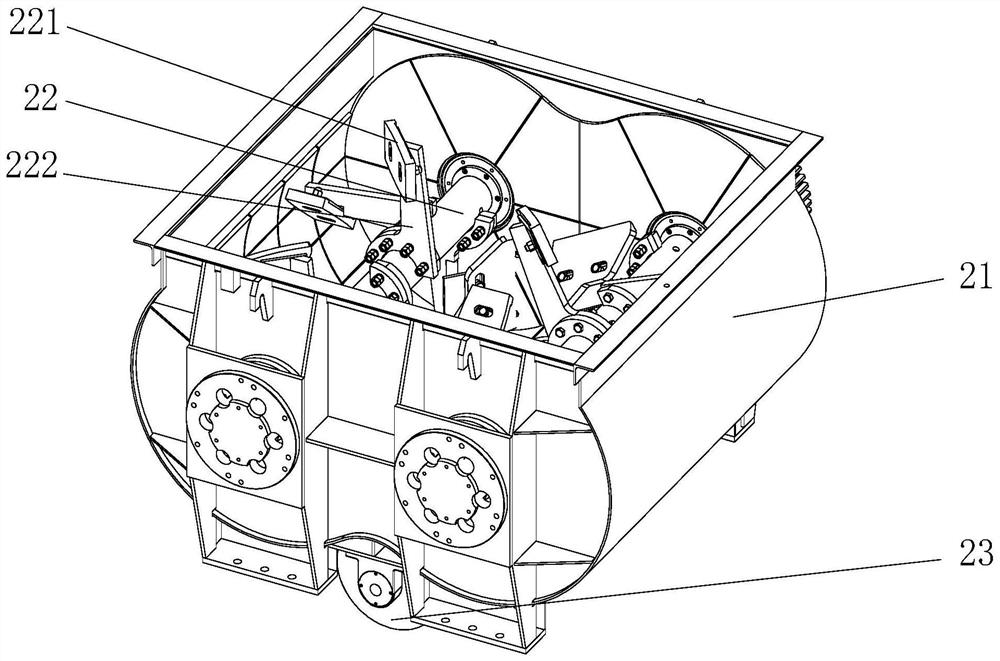

[0030] The mixing box 2 includes a box body 21, a stirring shaft 22 and a discharge mechanism 23. The upper end of the box body 21 is an open structure and is connected with the feed hopper 1, so that the raw materials in the feed ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com