Glycosyl polyethers, preparation method thereof and use thereof

A technology of sugar base and synthesis method, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve problems such as limited synthesis methods, and achieve the effects of easy availability of raw materials, easy control of conditions, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

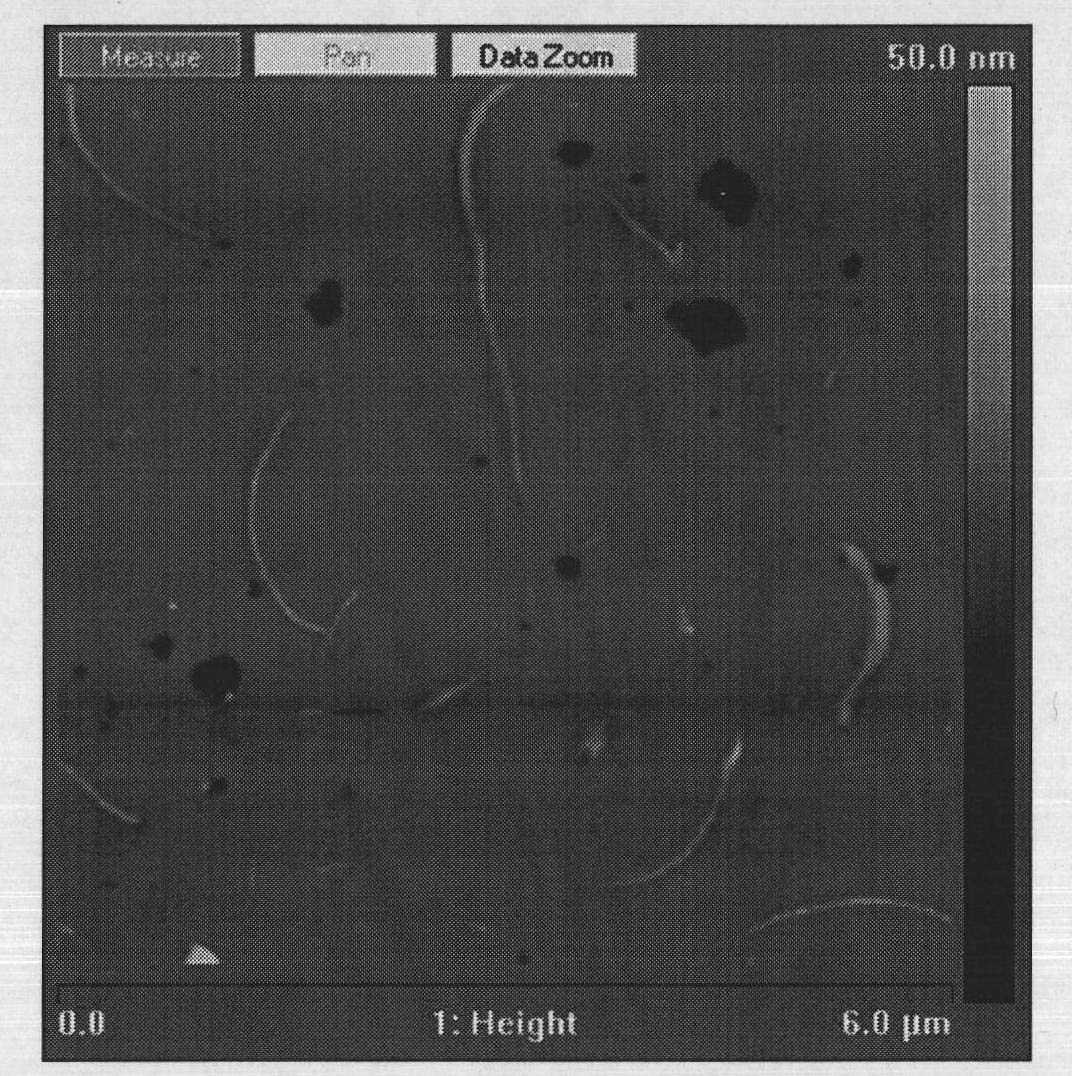

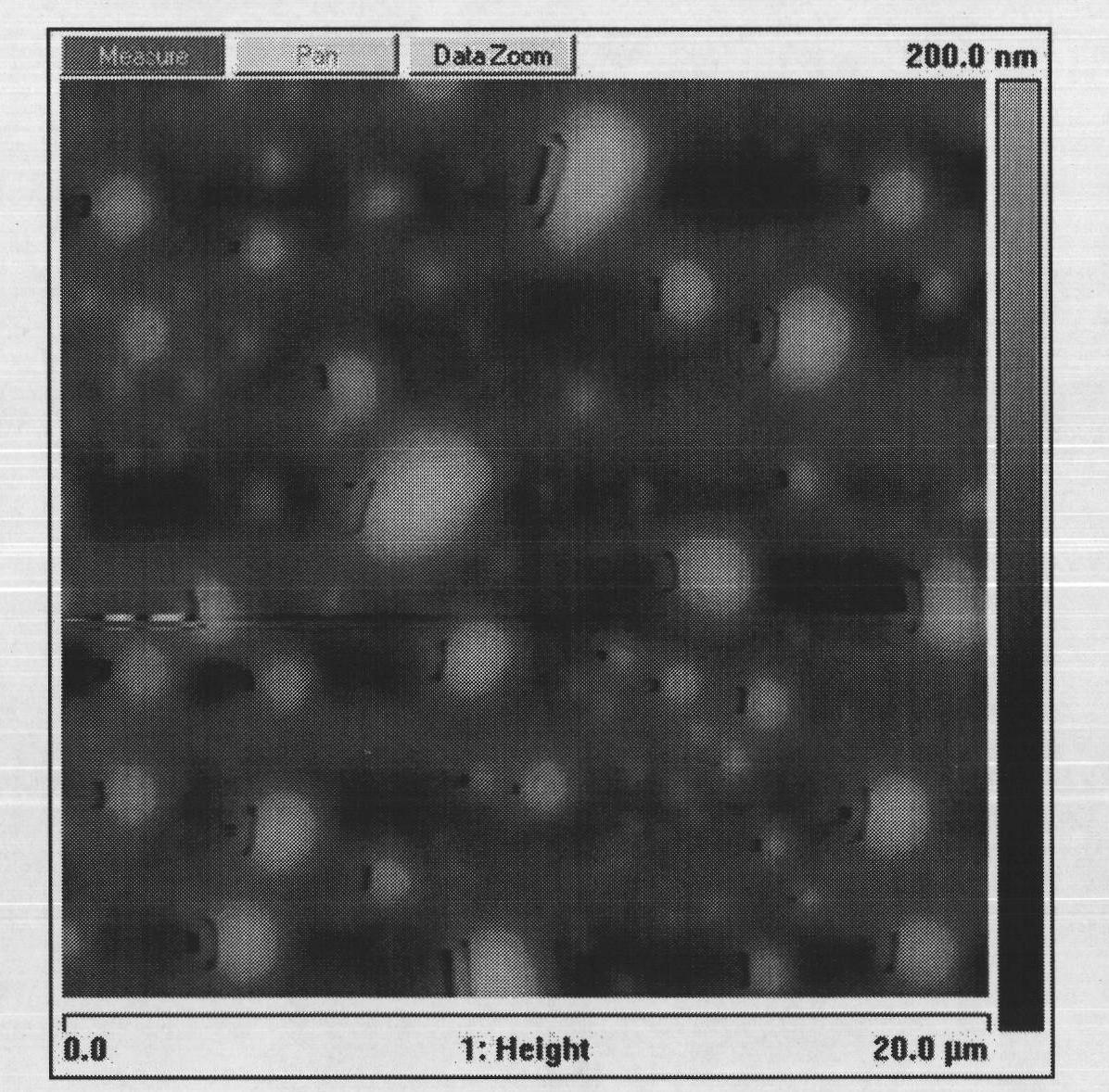

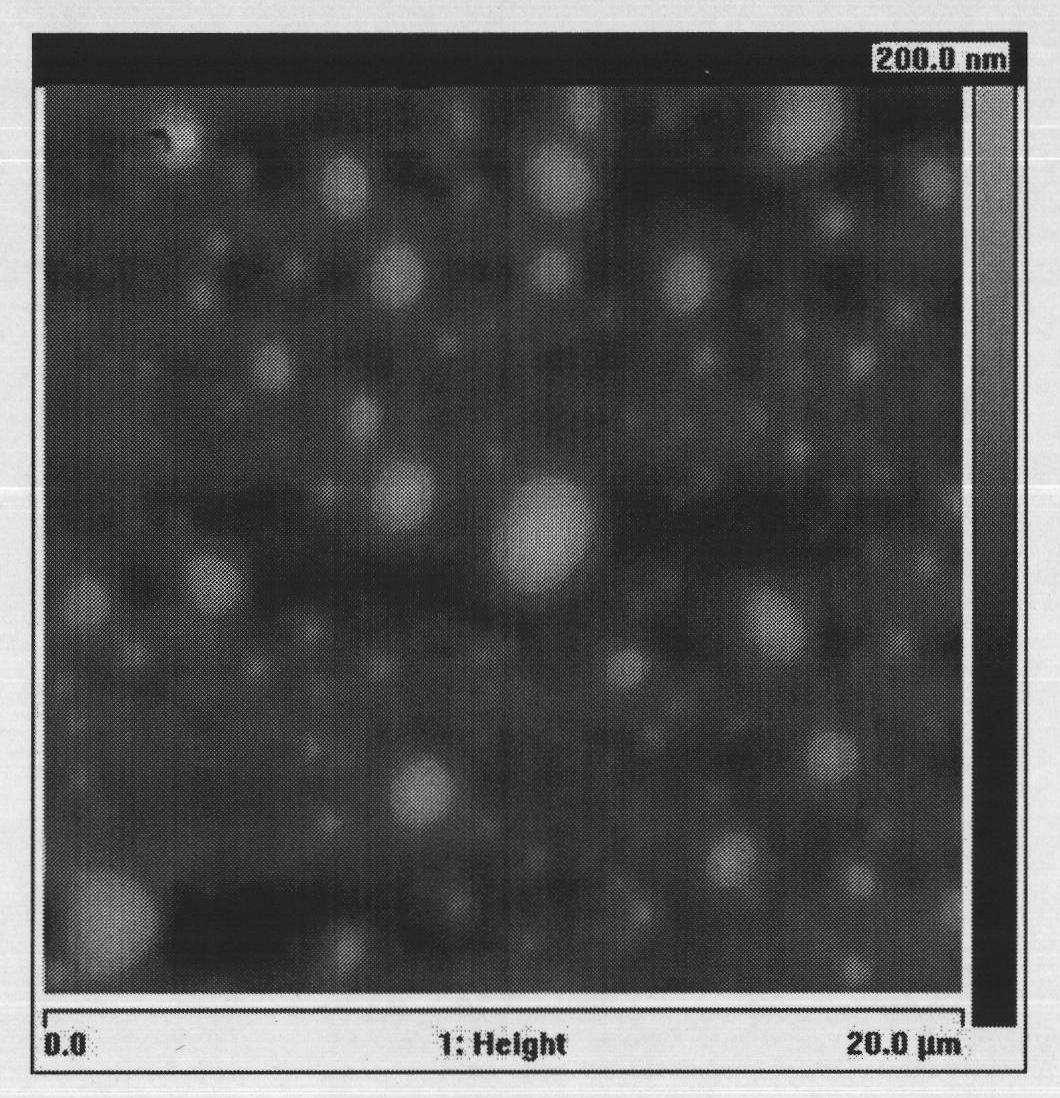

Image

Examples

Embodiment 1

[0049] Will help to understand the present invention by following example, but content of the present invention can not be limited:

[0050]

[0051] Compound 1 (142 mg, 0.30 mmol) was dissolved in 30 mL of dry tetrahydrofuran, TMSOTf (14 uL, 0.06 mmol) was added, stirred at room temperature for 15 min, and then poured into ice water to obtain a white suspension, which was filtered and dried to obtain a white solid 2 (THF conv: 4.7%). 1 H NMR (400MHz, CDCl 3 ): δ5.48(dd, 0.55H, J=10.0, 0.8Hz, H4α), 5.09-4.95(m, 2H, H1α, H3α, H4β, H3β), 4.39(d, 0.46H, J=8.0Hz, H1β), 4.29(dd, 1H, J=12.4, 4.4Hz, H6β, H6α), 4.15-4.00(m, 1.85H, H6β', H5α, H6α'), 3.41(m, 390H,), 2.05-1.99 (m, 9H, Ac), 1.62(m, 390H). 13 C NMR (75MHz, CDCl 3 ): δ170.4, 169.9, 169.6, 102.0, 97.8, 71.4, 70.7, 70.5, 68.8, 68.5, 67.9, 67.5, 63.7, 62.5, 61.8, 60.8, 26.5, 20.6.

[0052]

Embodiment 2

[0054]

[0055] Compound 3 (197 mg, 0.30 mmol) was dissolved in 30 mL of dry tetrahydrofuran, AgOTf (85 mg, 0.33 mmol) was added, stirred at room temperature for 9 minutes, and then poured into ice water to obtain a white suspension, which was filtered and dried to obtain a white solid 4 (THF conv: 4.6%). 1 H NMR (400MHz, CDCl 3): δ8.03-7.80(m, 8H), 7.59-7.25(m, 12H), 5.90(t, 1H, J=9.6Hz), 5.68(t, 1H, J=9.6Hz), 5.52(t, 1H, J=8.0Hz), 4.65(dd, 1H, J=12.4, 2.8Hz), 4.51(dd, 1H, J=12.0, 5.2Hz), 4.16(m, 1H), 3.41(m, 700H,) , 1.63(m, 700H). 13 C NMR (75MHz, CDCl 3 ): δ166.1, 165.8, 165.0, 133.4, 133.1, 133.1, 129.9, 129.8, 129.7(2C), 128.8, 128.4, 128.3(2C), 101.2, 72.9, 72.2, 71.9, 70.8(2C), 70.6, 70.4 (2C), 70.2, 70.1, 70.0, 69.8, 63.2, 62.7, 26.9, 26.7, 26.5, 26.3, 26.2, 26.0.

[0056]

Embodiment 3

[0058]

[0059] Compound 5 (167 mg, 0.30 mmol) was dissolved in 30 mL of dry tetrahydrofuran, 2,6-di-tert-butyl-4-methylpyridine (DTBMP) (123 mg, 0.60 mmol) was added, stirred at room temperature for 5 min, and AgPF was added 6 (113mg, 0.45mmol), stirred at room temperature for 15min and then poured into ice water to obtain a white suspension, which was filtered and dried to obtain a white solid 6 (THF conv: 6.6%). 1 H NMR (400MHz, CDCl 3 ): δ8.00(d, 2H, J=7.6Hz), 7.59-7.05(m, 18H), 5.25(t, 1H, J=8.0Hz), 4.83-4.70(m, 2H), 4.69-4.45( m, 5H), 3.90-3.70(m, 5H), 3.40(m, ~1092H,), 1.62(m, ~1092H). 13 CNMR (75MHz, CDCl 3 ): δ165.1, 138.1, 137.9, 137.8, 134.2, 134.0, 132.9, 132.0, 130.0, 129.7, 129.3, 129.1, 128.4, 128.3(2C), 128.2, 128.0, 127.8, 127.7, 127.6, 1208. ,75.2,75.0,73.8,73.5,71.4,70.7,70.6,70.4,70.1,69.7,69.4,68.8,67.4,62.6,30.2,29.6,27.3,26.8,26.6,26.5,26.3,26.0.

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com