Pressure actuated fuel injector

A technology of fuel injectors and injection valves, which is applied in the direction of fuel injection devices, injection devices, injection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following description is merely exemplary in nature and is in no way intended to limit the invention, its application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts or features.

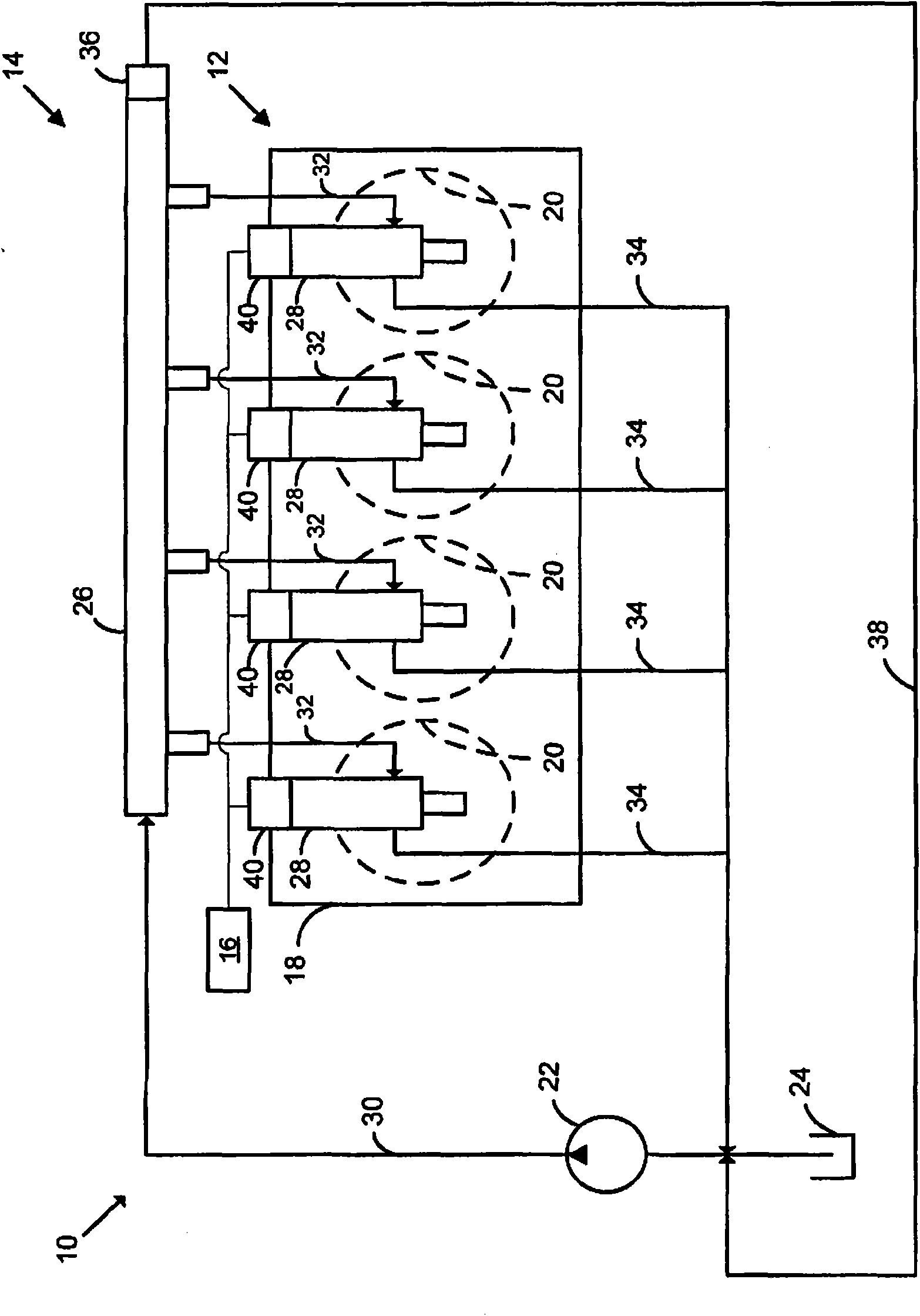

[0013] refer to figure 1 , an exemplary engine assembly 10 is schematically shown. Engine assembly 10 may include engine 12 and a control module 16 in communication with fuel system 14 . In the illustrated example, the engine 12 may include an engine block 18 that defines a plurality of cylinders 20 in communication with the fuel system 14 . Although engine 12 is shown as a four-cylinder engine in this disclosure, it should be understood that the present teachings apply to various engine configurations and are in no way limited to the configuration shown.

[0014] The fuel system 14 may include a fuel pump 22 , a fuel tank 24 , a fuel rail 26 , fuel injectors 28 , a main fuel supply line 30 , a seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com