Automatic substrate transport system and method

A technology for conveying systems and substrates, which is applied in the fields of electrical components, printed circuit manufacturing, photolithography process exposure devices, etc., can solve problems such as reducing production efficiency and prolonging manufacturing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following description is intended to enable those skilled in the art to reproduce and utilize the invention and to implement it using the best mode described by the inventors. There are various modifications to the invention which will be apparent to those skilled in the art. Any of these modifications, equivalent replacements and substitutions are within the inventive idea and scope of the present invention.

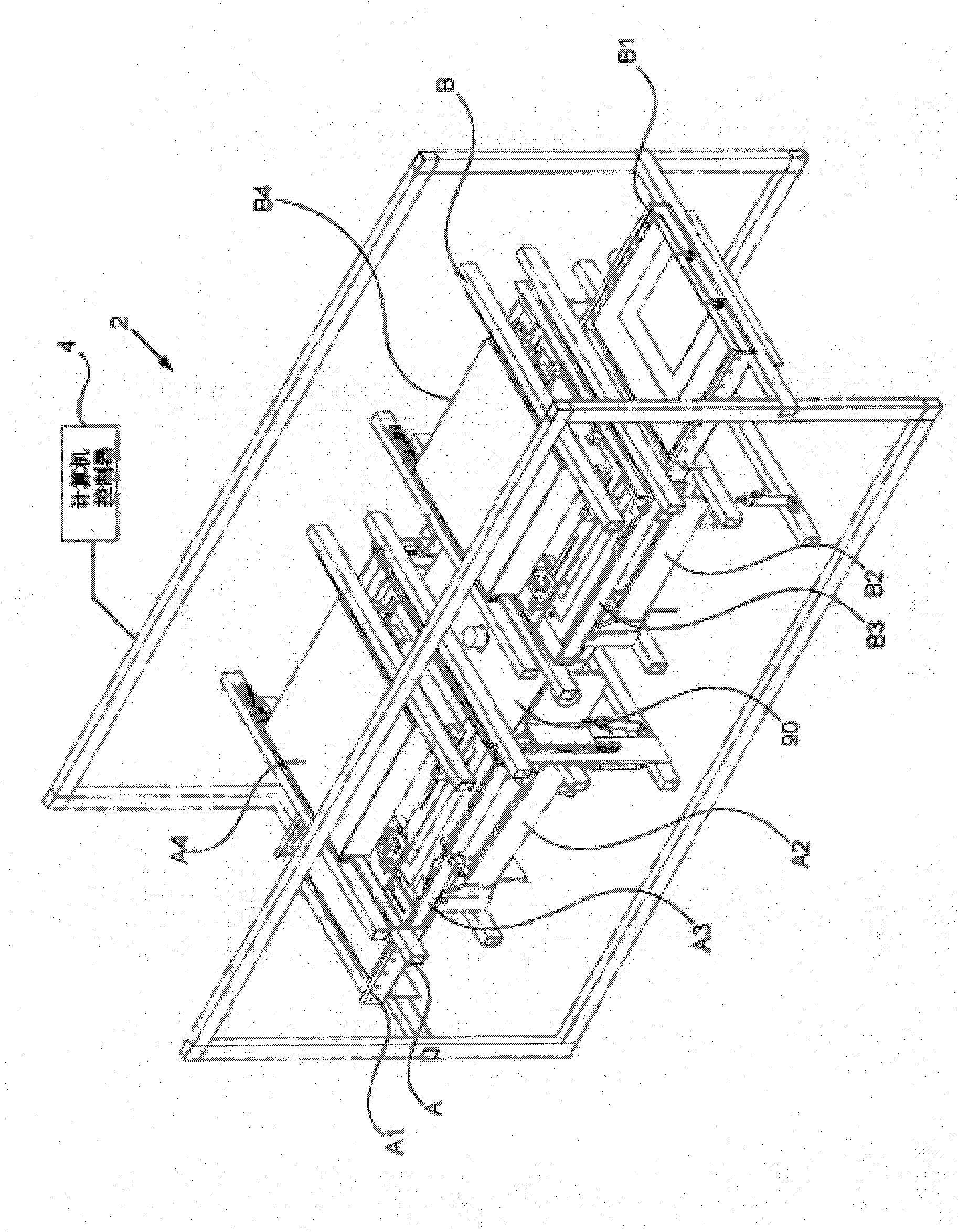

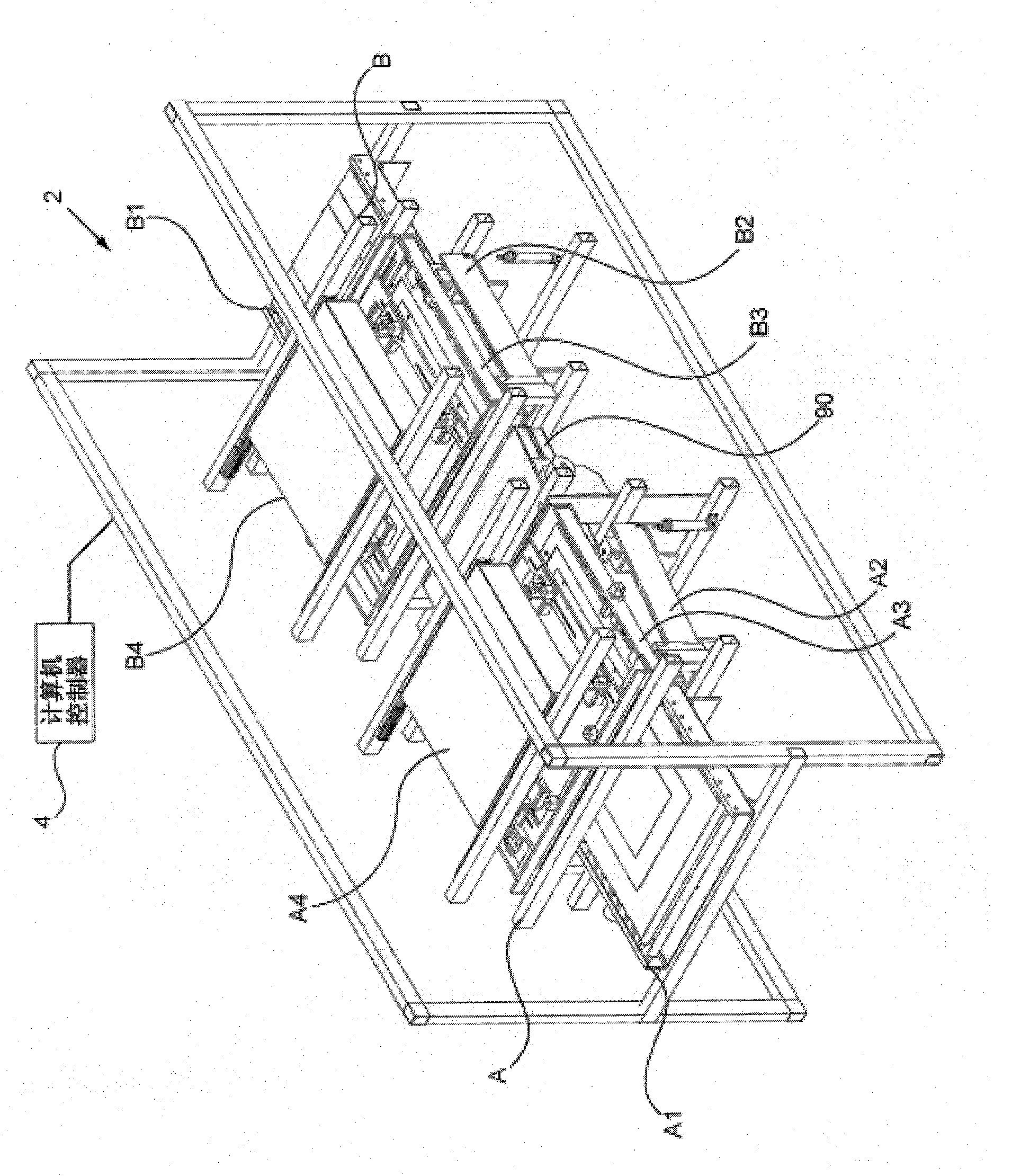

[0047] figure 1 An embodiment of the automatic substrate transfer system of the present invention is given. The automatic substrate transfer system 2 is mainly described as a specific system for processing PCB substrates. The teachings of the present invention can be applied to any substrate with photopolymerizable substances that needs to be treated with a UV exposure system. The System 2 can handle substrates ranging in size from 356mm x 356mm to 610mm x 720mm. Of course, the system can be adjusted to handle larger or smaller substrates as required. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com