Variable graphic anti-counterfeiting method with laser holographic effect

A technology of laser holography and graphics, which is applied to stamps, instruments, identification devices, etc., can solve the problems of complex process, low technical content of telephone anti-counterfeiting system, random numbers without anti-counterfeiting technology, etc., and achieve the effect of ensuring uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

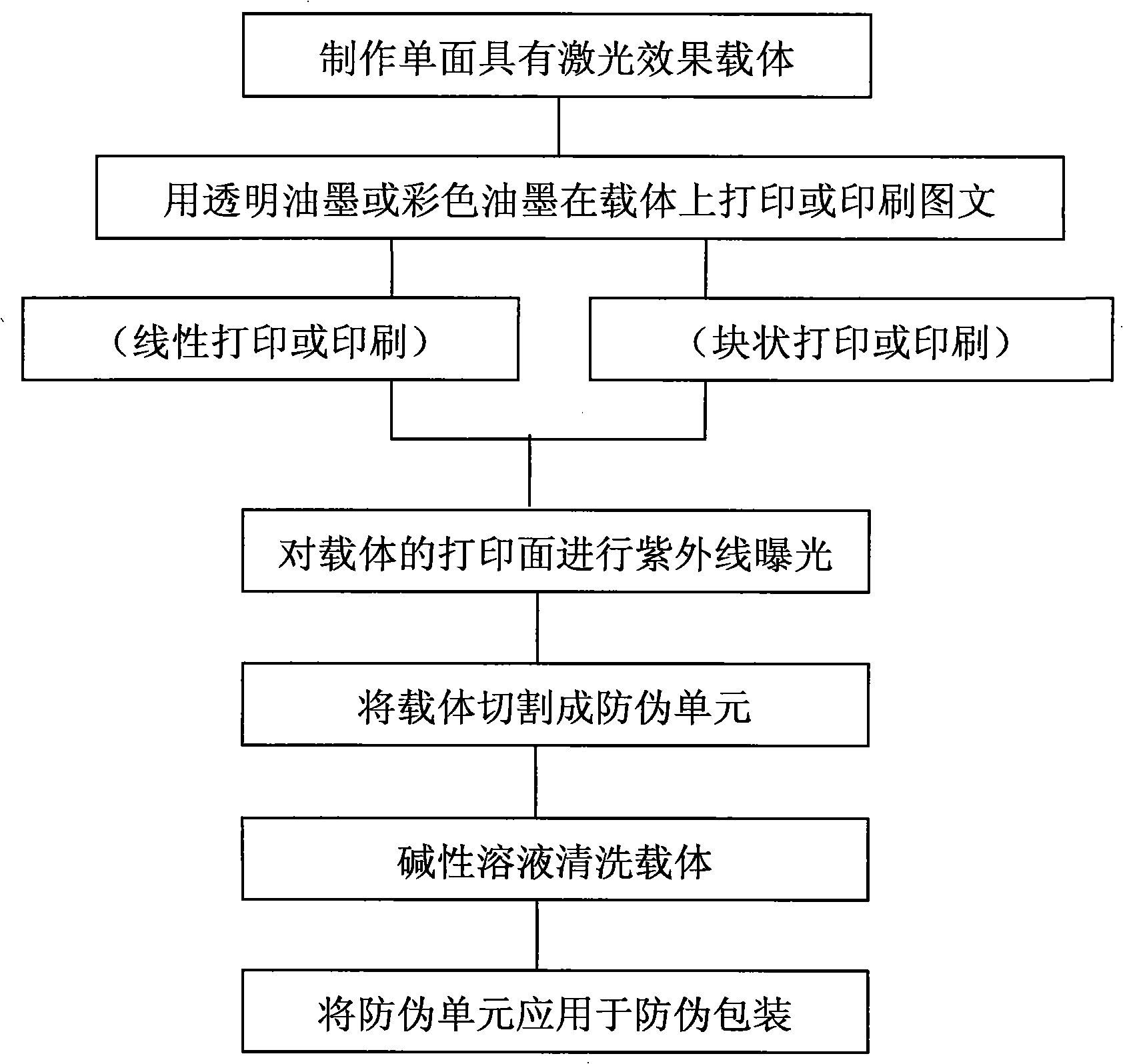

[0029] like figure 1 As shown, the anti-counterfeiting method in this embodiment specifically includes the following steps:

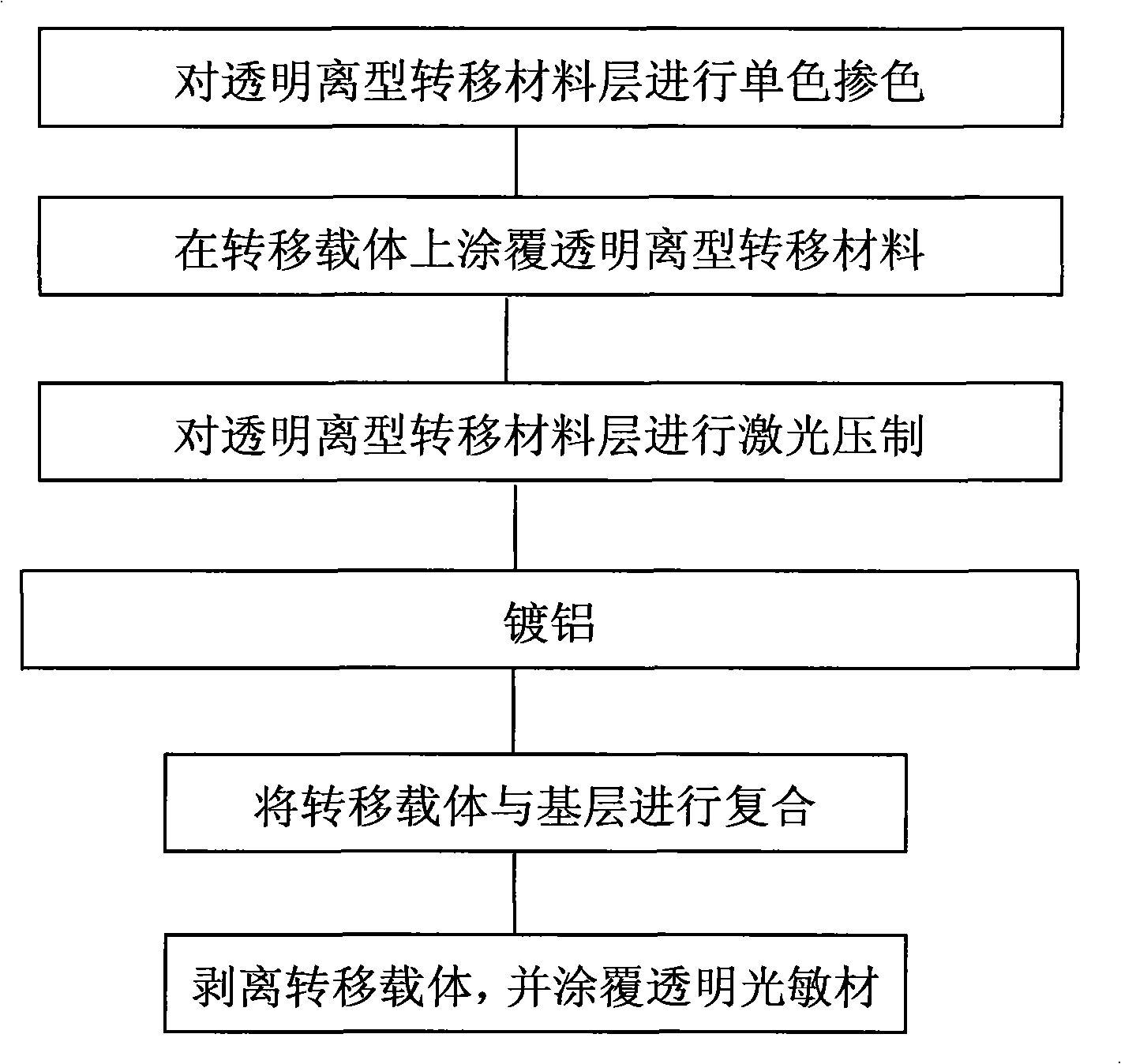

[0030] Step 1, making a carrier with a laser holographic effect on one side, the carrier at least includes a base layer, a metal layer and a transparent photosensitive material layer from bottom to top, and the side where the transparent photosensitive material layer is bonded to the metal layer is a laser pressing surface;

[0031] In step 2, digital printing or digital printing is used to print transparent ink or colored ink on the same surface of the transparent photosensitive material layer, and the printed or printed graphic units are different. If linear printing or graphic unit printing is adopted in step 2, then after step 5, the packaging pull line of linearly arranged graphic unit will be obtained; if block printing or graphic unit printing is adopted in step 2, then step 5 Before, it was necessary to coat the adhesive layer on the other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com