Integrated horizontal vibration machine and manufacturing method thereof

A vibrating machine, integrated technology, used in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of large error range of component characteristics, products with difficult resonance frequency, etc., and achieve subtle changes in component characteristics. Achieve single product, excellent effect on stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

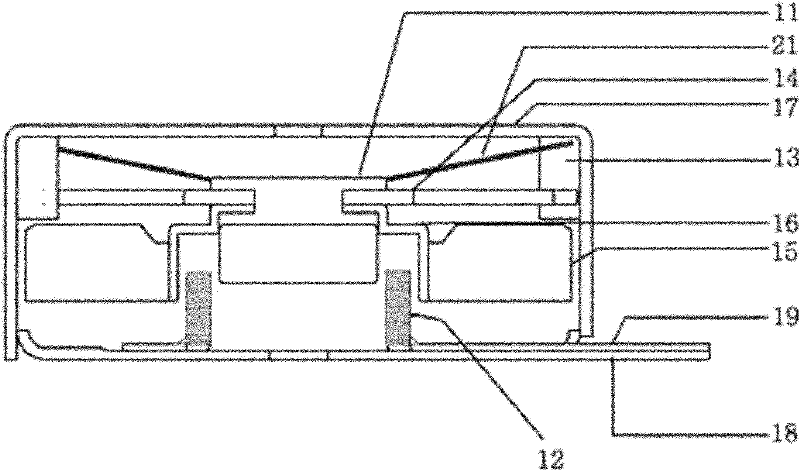

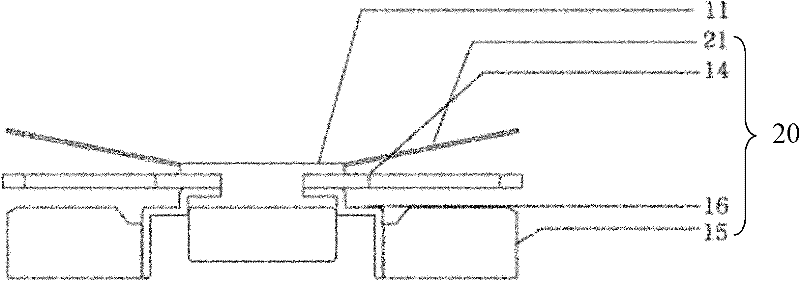

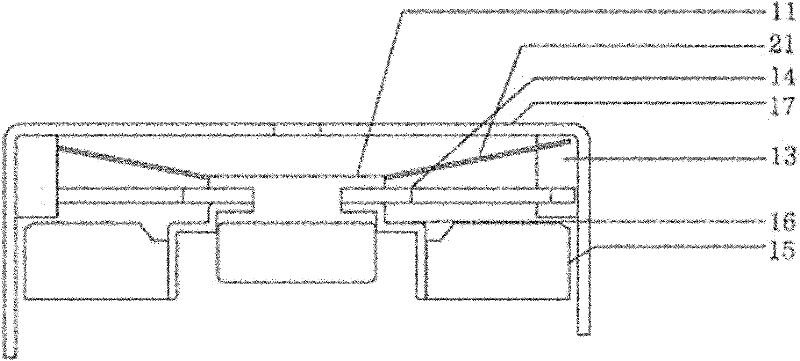

[0023] Such as Figure 1-3 As shown, a kind of integrated horizontal vibrating machine comprises the vibrating part 20 mainly made of annular permanent magnet 15, annular balance weight 16, leaf spring 14 and annular auxiliary spring 21, vibrating part fixed shell 17 and frequency applying part (not As shown in the figure); and the vibrating part 20 is integrated with the ring permanent magnet 15, the ring balance weight 16, the leaf spring 14 and the annular auxiliary spring 21 through the injection molding member 11; the integrated vibrating part 20 and The vibrator fixing case 17 is integrally formed by the secondary injection molding member 13 .

[0024] A method of manufacturing an integrated horizontal vibrating machine, which is to injection mold the combined part of the ring-shaped permanent magnet 15 constituting the vibration part 20, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com