High power direct current switching power supply system and power cabinet

A technology of DC switch and power supply system, which is applied in the direction of pull-out switch cabinet, DC power input conversion to DC power output, output power conversion device, etc. Reduce the work efficiency of the inspection and maintenance process to achieve the effect of ensuring continuous operation, convenient inspection and maintenance, and avoiding the disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

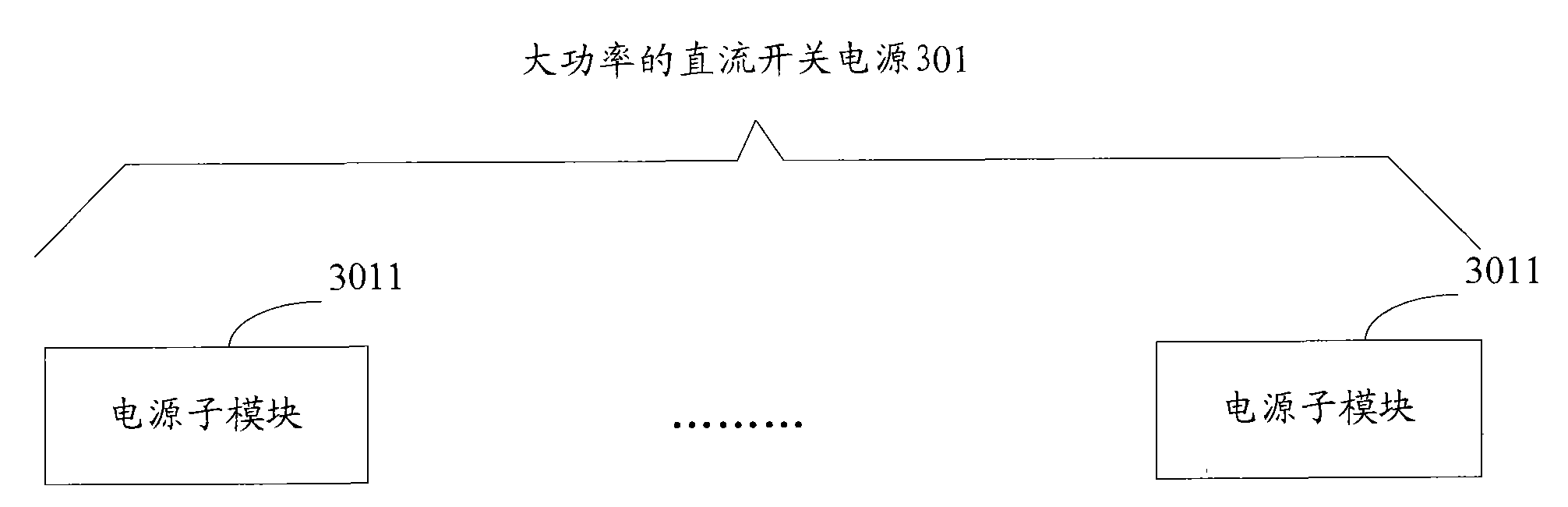

[0023] An embodiment of the present invention provides a high-power DC switching power supply system. The high-power DC switching power supply system includes: a high-power DC switching power supply and a power supply cabinet. The power supply cabinet is a drawer-type drawer cabinet. Wherein, the power cabinet is equipped with industrial sockets and power switch connectors, the input power is connected to the industrial socket through the plugs, and the output power is connected to the vertical busbar through the power switch connectors.

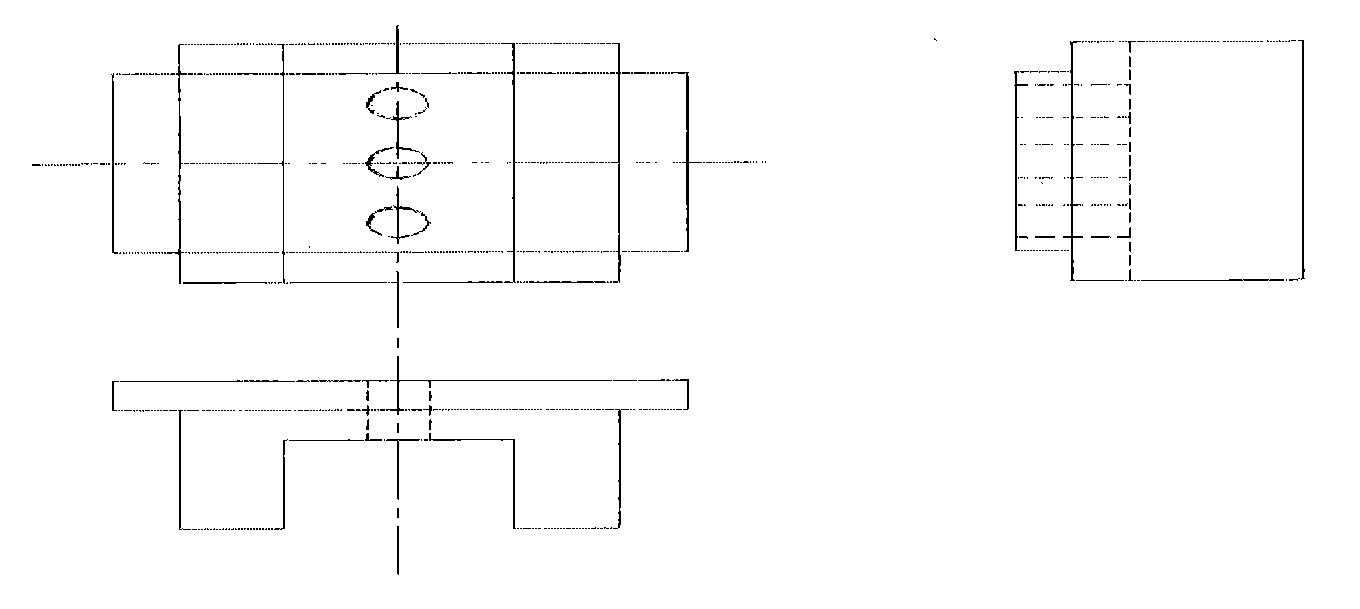

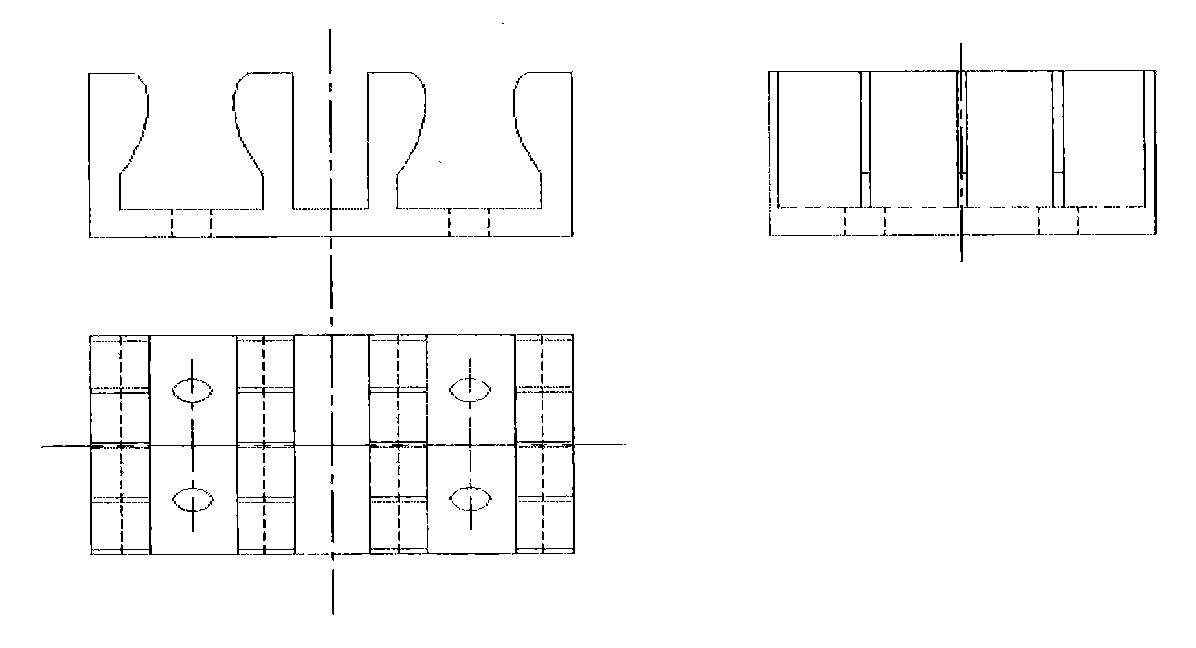

[0024] Among them, the high-power DC switching power supply converts 380 volts of AC power into a range of 5-30 volts of DC power output, and the input AC power is connected to the industrial socket on the power cabinet through a plug. Please refer to figure 1 , which is a schematic diagram of an input power supply connected to an industrial socket through a plug in the present invention. The output DC power is connected to the vertical busb...

Embodiment 2

[0033] Corresponding to the above-mentioned high-power DC switching power supply system, an embodiment of the present invention also provides a power supply cabinet. see Figure 4 , which is a schematic structural diagram of a power supply cabinet in the present invention, and the power supply cabinet 401 is a drawer cabinet.

[0034] It should be noted that, the embodiment of the present invention does not limit the number of drawers in the power cabinet. A preferred embodiment includes: at least two drawers 4011, each drawer is respectively equipped with a power sub-module, and each power sub-module includes a power unit and a control unit.

[0035] The power cabinet 401 is equipped with industrial sockets and power switch connectors. The input power is connected to the industrial socket through the plugs, and the output power is connected to the vertical busbars through the power switch connectors.

[0036] It can be seen from the above-mentioned embodiments that when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com