Washing machine

A washing machine and washing container technology, applied in the field of washing machines, can solve the problems of large assembly cost and component cost, and achieve the effect of simplifying assembly and reducing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

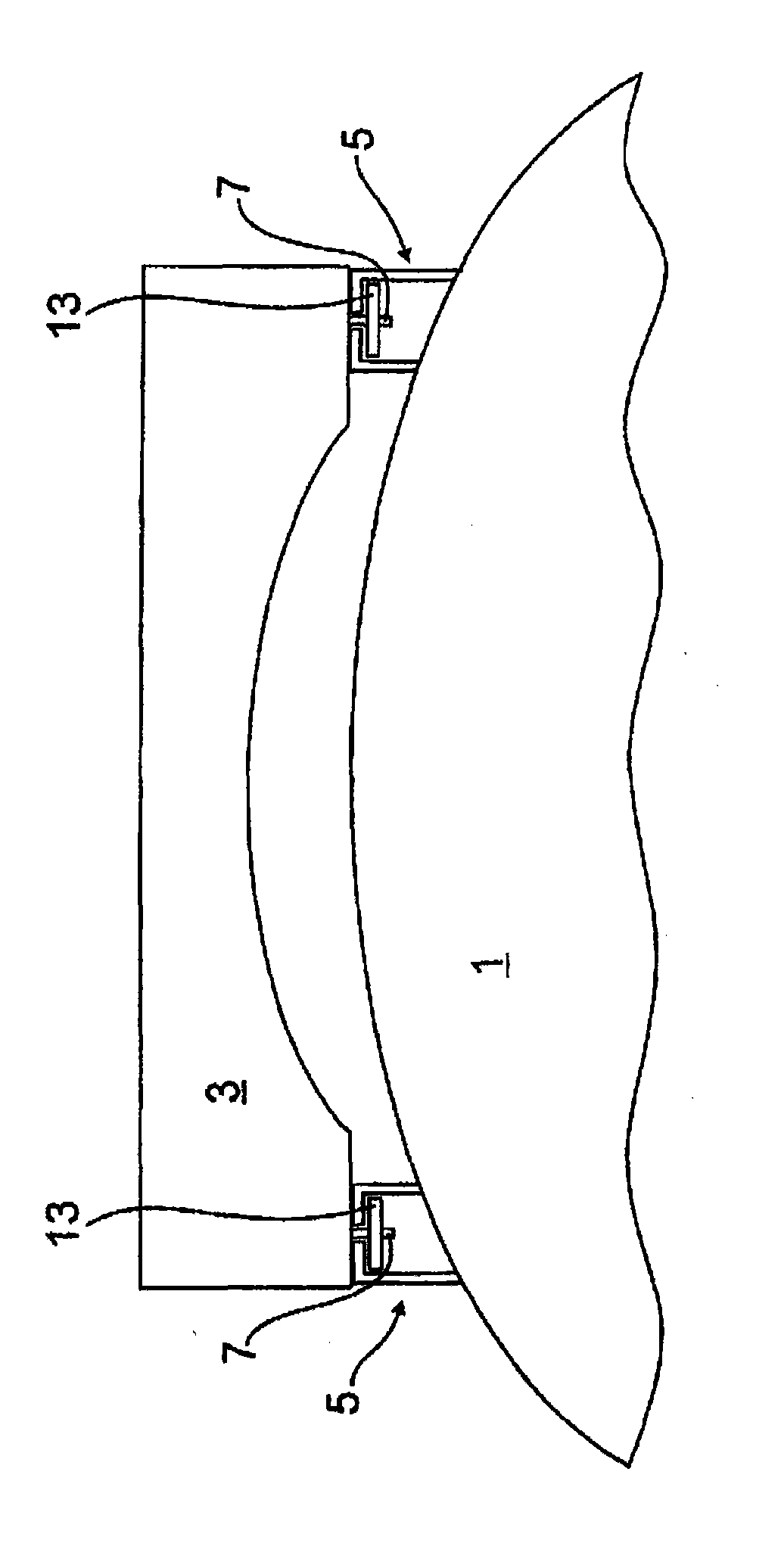

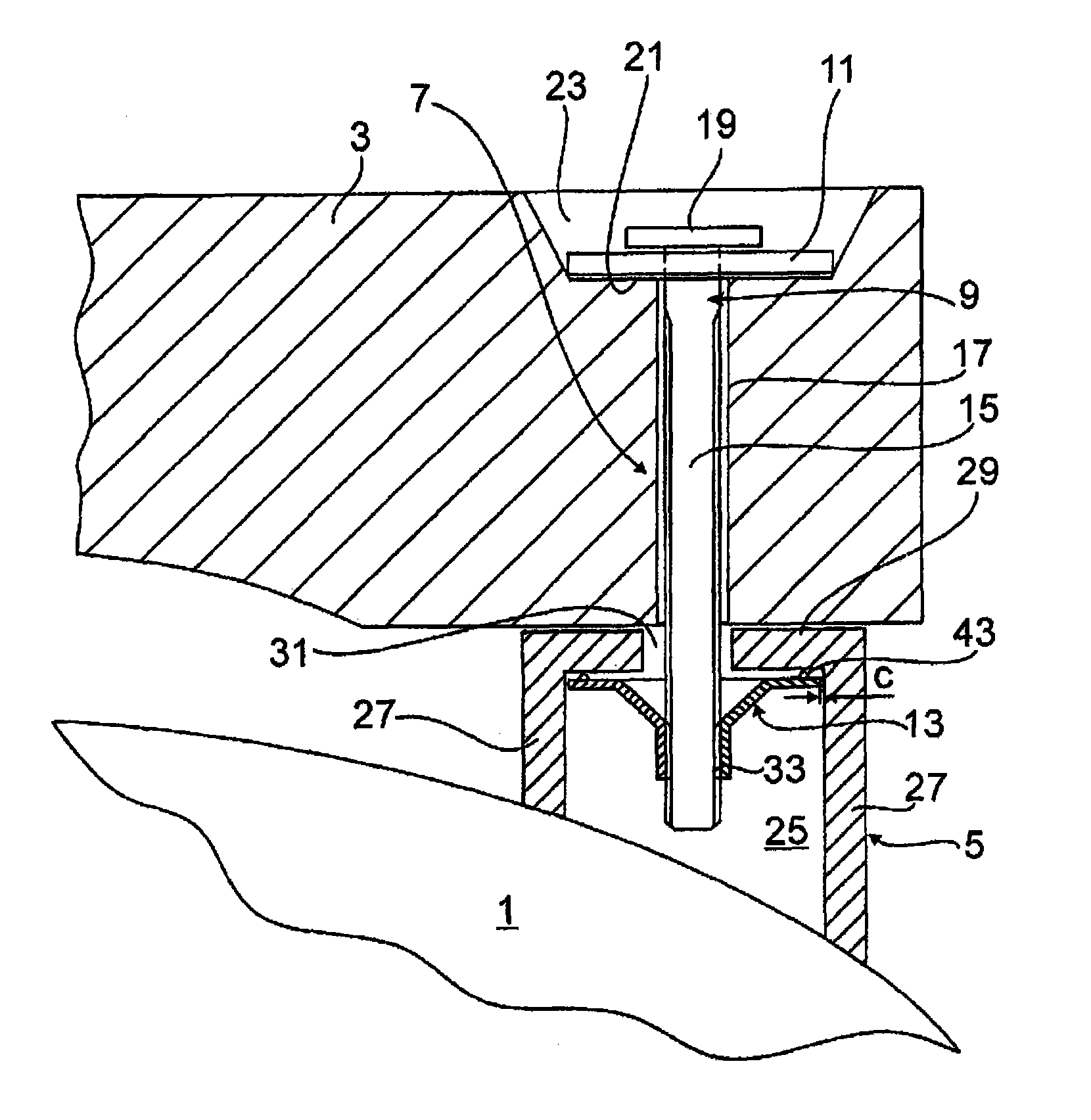

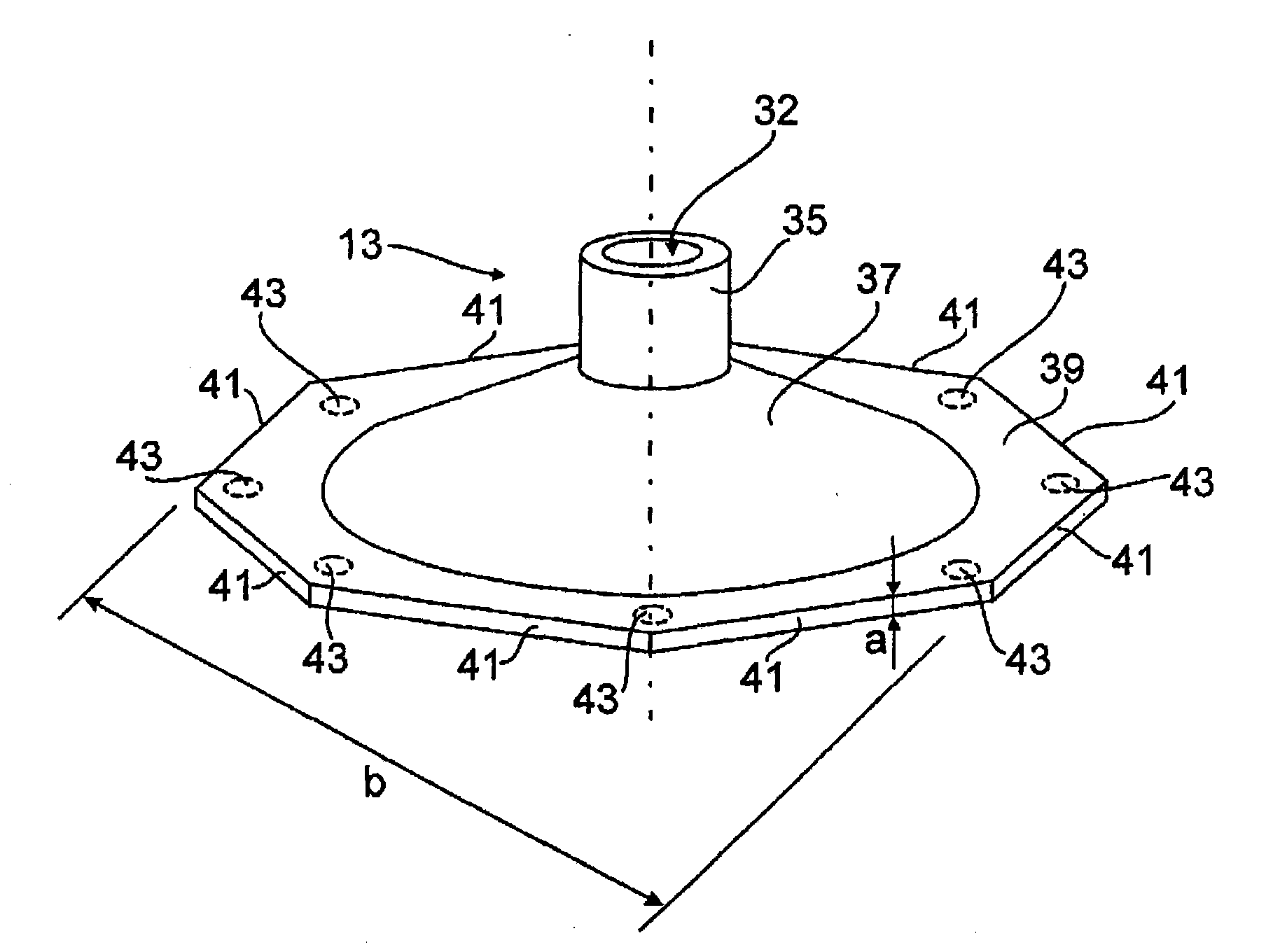

[0031] exist figure 1 shows in a schematic side view a partial area of a washing container 1 of a washing machine and a counterweight 3 fastened to the washing container 1 on the upper side, which balance weight ensures a balanced washing operation. The elongated counterweight 3 extends transversely to the center axis (not shown) of the hollow-cylindrical washing container 1 and rests at its two opposite ends on a hollow-profile support 5 of the washing container 1 . The balancing weights 3 are attached at their longitudinal ends each via a screw connection 7 to an associated hollow-profile support 5 of the washing container 1 .

[0032] The balancing weight 3 is produced in a known manner from a cast material such as cast iron or concrete or another suitable material. The washing container 1 is an injection molded part of synthetic material. The hollow profile support 5 is molded integrally on the washing container 1 in a simple manner in terms of production technology. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com